T.O. 1-1A-9

SECTION II

FERROUS (STEEL) ALLOYS

2-1. CLASSIFICATION.

2-2. SAE NUMBERING SYSTEM. A numeral index system is used to identify the compositions of the SAE steels, which

makes it possible to use 'numerals that are partially descriptive of the composition of material covered by such numbers.

The first digit indicates the type to which the steel belongs; for example "1" indicates a carbon steel; "2" a nickel steel;

and "3" a nickel chromium steel. In the case of the simple alloy steels, the second digit generally indicates the

approximate percentage of the predominant alloying element. Usually the last two or three digits indicate the

approximate average carbon content in "points" or hundredths of 1 percent. Thus "2340" indicates a nickel steel of

approximately 3 percent nickel (3.25 to 3.75) and 0.40 percent carbon (0.38 to 0.43). In some instances, in order to

avoid confusion, it has been found necessary to depart from this system of identifying the approximate alloy composition

of a steel by varying the second and third digits of the number. An instance of such departure is the steel numbers

selected for several of the corrosion--and heat resisting alloys.

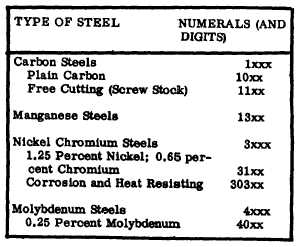

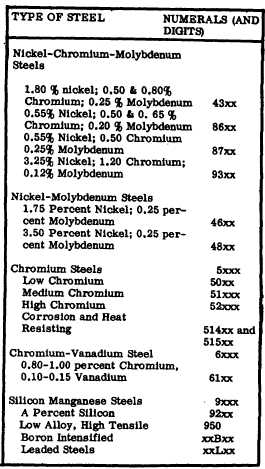

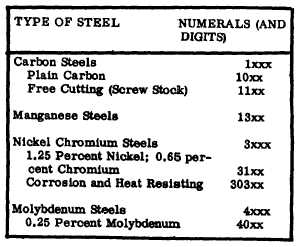

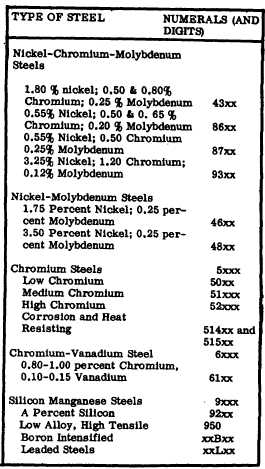

2-3. The basic numerals for the various types of SAE steel are:

2-4. CARBON STEELS, Steel containing carbon in percentages rant from 0.10 to 0.30 percent is classed as low carbon

steel. The equivalent SAE numbers range from 1010 to 1030. Steels of this grade are used for the manufacture of

articles such as safety wire, certain nuts, cable bushing, etc. This steel in sheet form is used for secondary structural

parts and clamps and in tubular form for moderately stressed structural parts.

2-1