15. Use a razor knife to remove any frayed hel-

met fibers resulting from drilling.

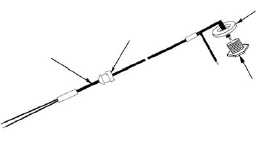

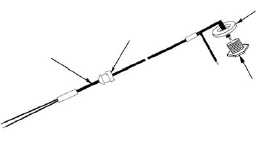

16. Referring to Figure 4-12.3, View, A, slide the

large black spacer over the wires of the inter-

face harness and onto the connector.

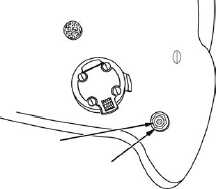

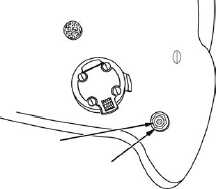

17. From outside the helmet, insert the black and

white wires of the interface harness through

the drilled hole so that the grommet is com-

pletely through hole, the head of the connec-

tor is against the spacer, and the spacer is

against the outside of the helmet as shown

in Figure 4-12.3, View B.

NOTE

The earcup grommet may be difficult to pull

through the helmet shell.

CAUTION

Do not twist the connector. The interface wire

on the back of the connector may

break if you do.

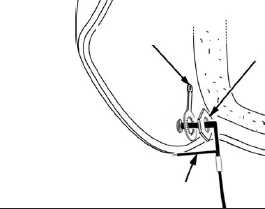

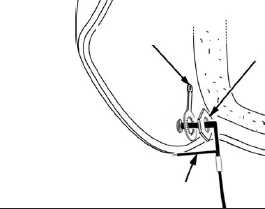

18. From inside the helmet, slide the ground lug

over the wires and onto the connector, fol-

lowed by the nut. Ensure that the unattached

ground wire is pulled through the ground lug

and nut as shown in Figure 4-12.3, View C.

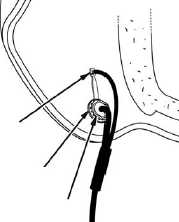

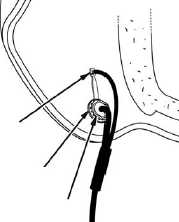

19. Ensure that the ground lug is oriented toward

the crown of the helmet as shown in Figure

4-12.3, View D. Tighten the nut using the

7/16-inch open-end wrench. Ensure that the

nut is tight enough that the ground lug will not

rotate when pushed.

NOTE

In Step 20, ensure that the soldering is per-

formed by qualified personnel, and

in accordance with ANSI/J-STD-001.

20. Using long-nose pliers, carefully bend the

ground lug to about a 45-degree angle from

the shell so that it reaches the unconnected

ground wire. Insert the stripped end of the

unconnected ground wire through the small

hole at the end of the ground lug. Wrap the

exposed part of the wire once around the

end of the ground lug. Solder the wire.

Bend the ground lug flush with the inside

surface of the helmet shell.

Figure 4-12.3. Connector Installation

VIEW A

VIEW C

(INSIDE

HELMET)

VIEW D

(INSIDE

HELMET)

INTERFACE

HARNESS

SPACER

CONNECTOR

EARCUP

GROMMET

VIEW B

(OUTSIDE

HELMET)

CONNECTOR

SPACER

GROUND LUG

NUT

UNATTACHED GROUND WIRE

WIRE TO BE

SOLDERED

GROUND LUG

NUT

Change 3

4-18.3

TM 1-8415-216-12&P