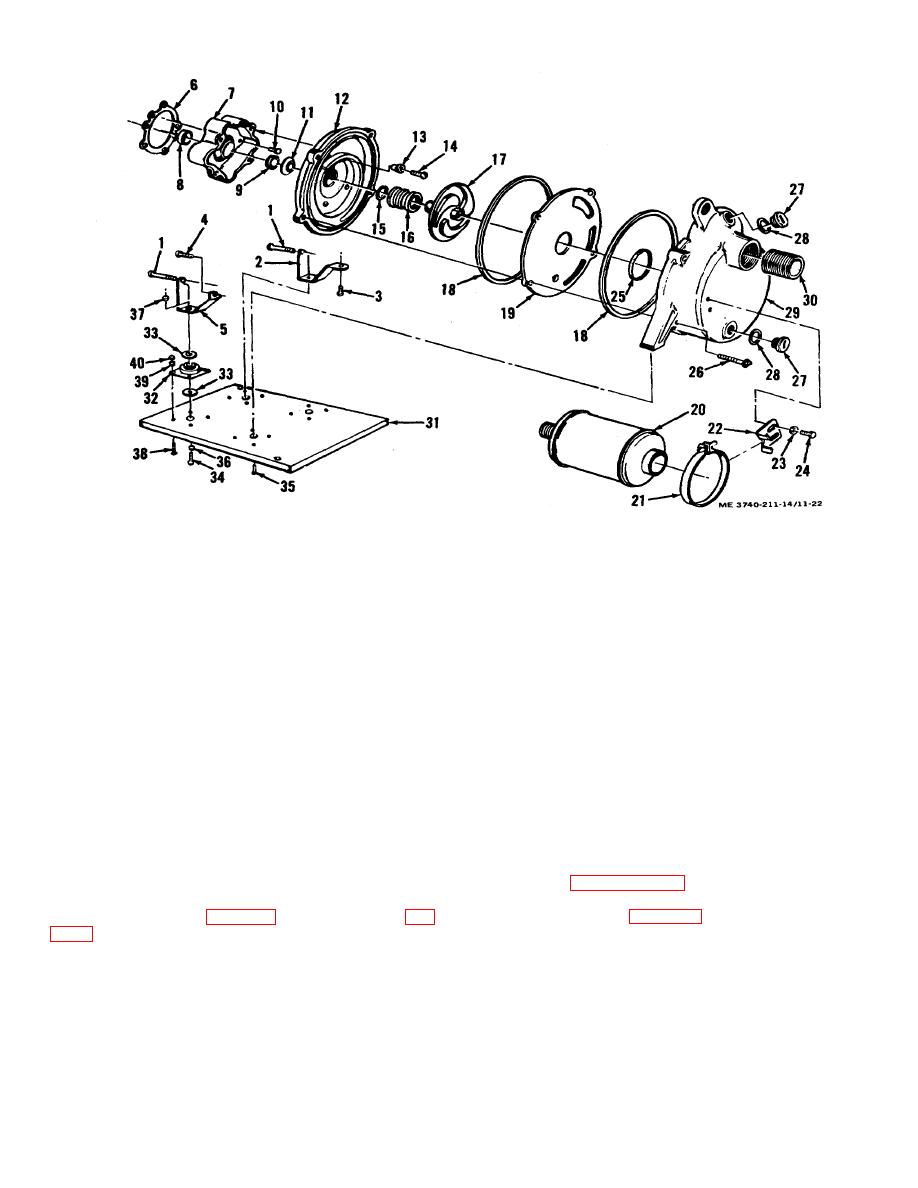

1. Screw, hex hd, 12-24 x

12. Impeller housing

23. Lock washer (2 reqd)

33. Snubbing washer (8 reqd)

1-11/16 (2 reqd)

13. Sealing washer (4 reqd)

24. Screw, hex hd, 1-20 x

34. Screw, Y4-20 x 1-24

2. Left leg

14. Screw, pan hd, 12-24 x

% (2 reqd)

2 reqd)

3. Screw, hex hd, 12-24 x %

% (4 reqd)

25. Gasket

35. Screw, Y4-20 x 1 (2 reqd)

%7

36. Lock washer, 1Y in.

4. Screw, hex hd, 12-24 x

15. Shim (as reqd)

26. Screw, hex hd, %-20 x

5. Right leg

16. Seal assembly

% (4 reqd)

(4 reqd)

6. Gasket

17. Impeller

27. Drain and filler cap

37. Nut, %-20 (2 reqd)

18. Gasket, 6-%s in. ID

7. Bearing housing

(2 reqd)

38. Screw, flat hd, No. 10

8. Needle bearing

(2 reqd)

28. Gasket (2 reqd)

(16 reqd)

9. Seal

19. Wear plate

29. Pump housing

39. Lock washer, No. 10

10. Screw, hex hd, 12-24 x

20. Muffler

30. Fitting, 1-% in

(16 reqd)

9/16 (5 reqd)

21. Muffler strap with screw

31. Pump base

40. Nut, hex No. 10 (16 reqd)

11. Slinger

22. Muffler bracket

32. Vibration mount (4 reqd)

Figure 11-22. Pump assembly - exploded view.

(3) Assembly.

end of fabricated seal assembling plug (fig. 1112), with

(a) Install inlet fitting (30) in pump housing

the open end of the seal facing the needle bearing Install

(29). Use Military Specification MILT27730 teflon tape

the seal from the interior of the bearing housing.

on pipe threads.

(e) Complete installation of pump assembly as

(b) Install gaskets (28), and drain and filler

instructed in paragraph 11-12, step c(2).

caps (27) in pump housing (29).

g. Repair of Ball Shutoff Valve.

(c) Using the short shoulder end of fabricated

(1) Disassembly (fig. 11-23).

bearing and seal tool (fig. 11-11), press bearing (8, fig.

(a) Remove two nuts (1) and handle (2) from

stem (12).

Press against lettered end of bearing only,

(b) Remove bell washer (3), follower (4), and

from outside of bearing housing.

stem seal (5) from stem (12).

(d) Using a new seal (9), greased to protect it

(c) Remove four nuts (6) and four bolts

from damage, place the seal on the long .

11-39