(20, fig. 11-22)

to exhaust manifold as instructed in

(3) Push the throttle button (4) all the way in.

step c (5), preceding.

Start engine and pump water at open discharge. When

e. Fuel Line Replacement. If replacement of the

engine is fully warmed up, adjust the main mixture

adjustment needle for the highest pumping speed

flexible fuel line (19, fig. 11-20) is required, heat ends of

obtainable. Then, open the needle 1/8 turn more.

the new fuel line in a pot of boiling water until they are

soft. While soft, stretch ends over the fitting as required.

CAUTION

This softening is required only on new fuel lines. Once

The screws holding the governed

they are stretched, they will retain their shape.

speed adjust clamp (2) should never

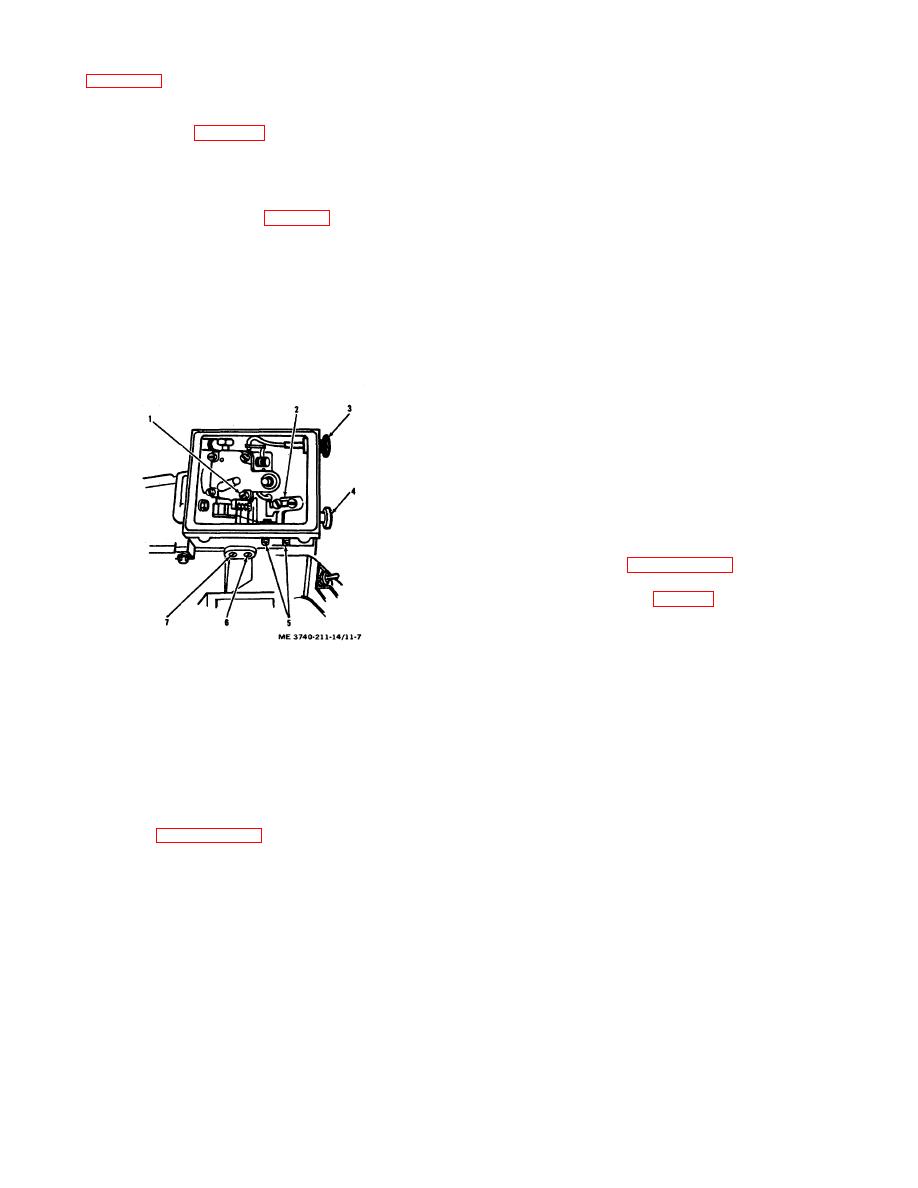

f. Carburetor Adjustment (fig. 11-7).

be loosened, except by direct support

or general support personnel with

Note:

proper test equipment available.

Before changing the carburetor mixture

(4) Pull the throttle button (4) all the way out,

adjustments, be sure the tank is full of

and adjust the idle mixture adjustment needle (7) for the

clean, fresh, properly mixed fuel. Then

smoothest and highest speed obtain-able. If this speed

clean the air filter, and leave the filter

is either too high or too low, adjust speed by means of

and cover off until the carburetor has

the idle speed adjustment screw (1).

been adjusted.

Note:

Because main and idle mixture

adjustment needles are interdependent,

some readjustment under full load

conditions may be necessary.

(5) Recheck adjustments under full load

conditions as in steps (2), (3), and (4), preceding. Be

sure settings are correct before reinstalling the air filter

and cover.

(6) Reinstall air cleaner filter element and

g. Removal and Replacement of Hoses, Couplings,

Strainer, and Ball Valve (fig. 11-1).

(1) All threaded connections of the pump (1),

hoses (8), couplers (4), strainer assembly (11), ball valve

(2), and valved nipples (5), use pipe threads. Removal

and replacement procedures are therefore identical for

1. Idle speed adjustment

5. Throttle rod adjustment

each. To remove, use a pipe wrench, strap wrench, or

screw

screws

vise to hold one part, while unscrewing the mating part

2. Governed speed adjust- 6. Main mixture adjustment

with a second wrench.

ment clamp and screws

needle (HI)

3. Choke button

7. Idle mixture adjustment

(2) Disconnect mated valved couplers by

4. Throttle button

needle (LO)

pulling back the retaining ring of the female half of the

coupler, and pull the coupling halves apart.

Figure 11-7. Carburetor adjustment controls.

(3) Clean threads of all components before

reattaching. Remove all dirt, spray fluid residue, tape, or

(1) Remove and clean the air cleaner element

(4) Apply a new layer of Teflon tape per

CAUTION

Military Specification MILT-27730, to pipe threads before

Use care when adjusting needles not

reattaching.

to jam needles in their orifices.

(5) Connect mating parts and screw down

(2) Very gently turn the idle mixture

fairly snug. Since pipe threads are tapered, it is not

adjustment needle (7), and the main mixture adjustment

necessary to overtighten them. However, do not back

needle (6) until they just close against their seats. Then

threads off from their tightest position, as a leak may

open both needles one turn from the gently closed

occur.

position.

11-12