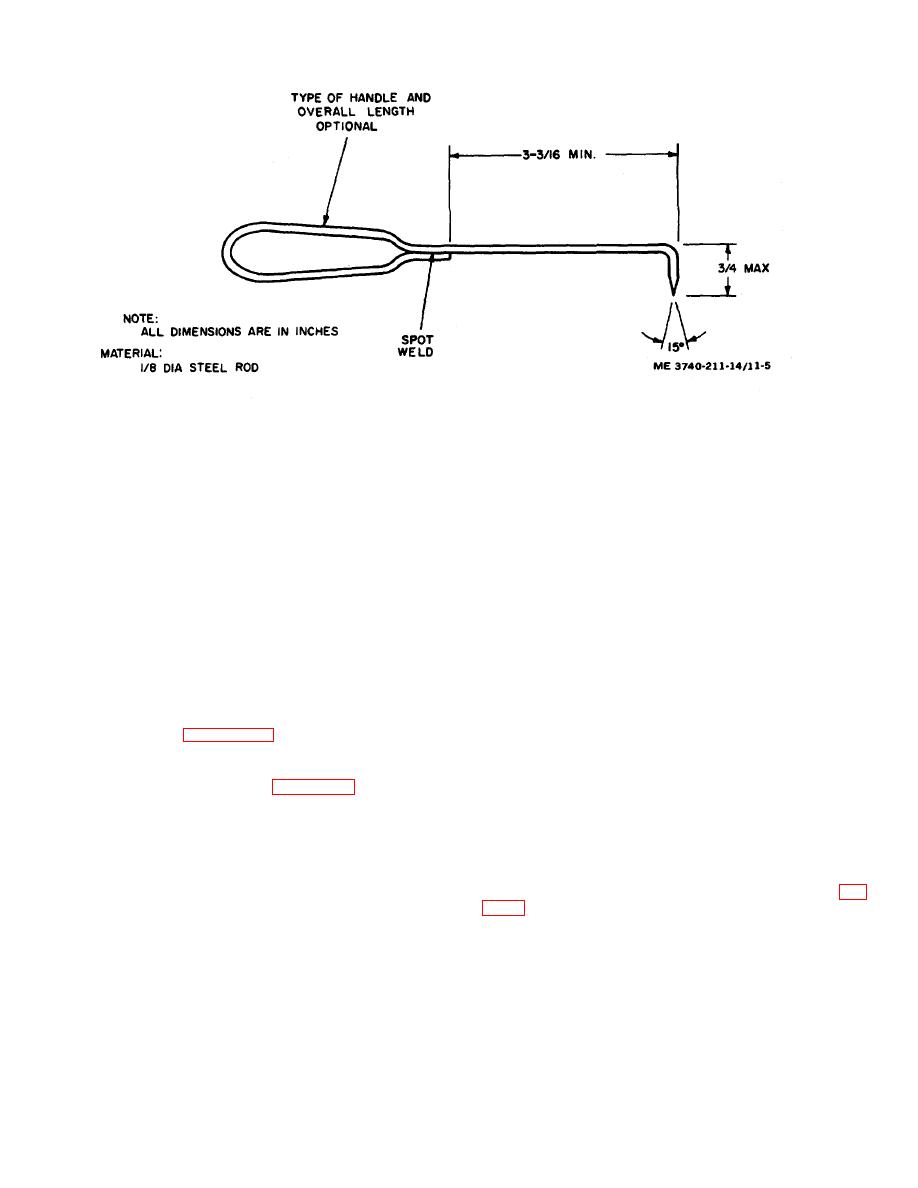

Figure 11-5. Fabrication of muffler cleaning tool.

c. Maintenance Repair Parts.

Repair parts and

from rear end of spark plug while pulling

starter handle (this may require two

equipment covering organizational maintenance for the

men) If sparks do not jump, the trouble

liquid loading system are listed and illustrated in TM 5-

is in the electrical system. (Report this

3740-211-24P.

condition to direct support maintenance.)

If sparks jump, replace spark plug. If

11-7.

Preventive Maintenance Checks and

this does not correct the problem, the

Services

trouble is in the fuel system. Check fuel

a. General. Insure that the liquid loading system is

lines, fuel tank, and carburetor.

ready for operation at all times. Inspect the equipment

systematically so that defects may be discovered and

11-8.

Maintenance of Liquid Loading System

corrected before they result in serious damage or failure.

a. General. Instructions in this paragraph are to

Perform necessary preventive maintenance checks and

inform and guide organizational maintenance personnel

services listed in step b, following. Item numbers

in maintaining the liquid loading system.

indicate the sequence of minimum inspection

b. Spark Plug Service.

requirements.

(1) A fouled or dirty spark plug which has

b. Organizational Preventive Maintenance Checks

caused trouble will often prove serviceable after it has

and Services.

been thoroughly cleaned, washed, and properly gapped.

maintenance checks and services applicable to

organizational maintenance.

CAUTION

tabulation of troubleshooting activities pertinent to

When setting spark plug gap be sure

organizational maintenance. The chart serves only as a

not to damage electrodes or

guide and does not preclude the possibility of other

insulator.

troubles existing.

(2) Service spark plug as follows:

Note:

(a) Carefully unscrew spark plug (HI-

A quick check of pump condition for

tension) lead (43, 11-15) from end of spark plug (41, fig.

troubleshooting

purposes

is

to

disconnect shielded ignition cable from

(b) Using a 13/16-inch deep socket

spark plug and hold end of the cable

wrench, remove the spark plug and gasket (41 and 42).

approximately /4 inch

11-8