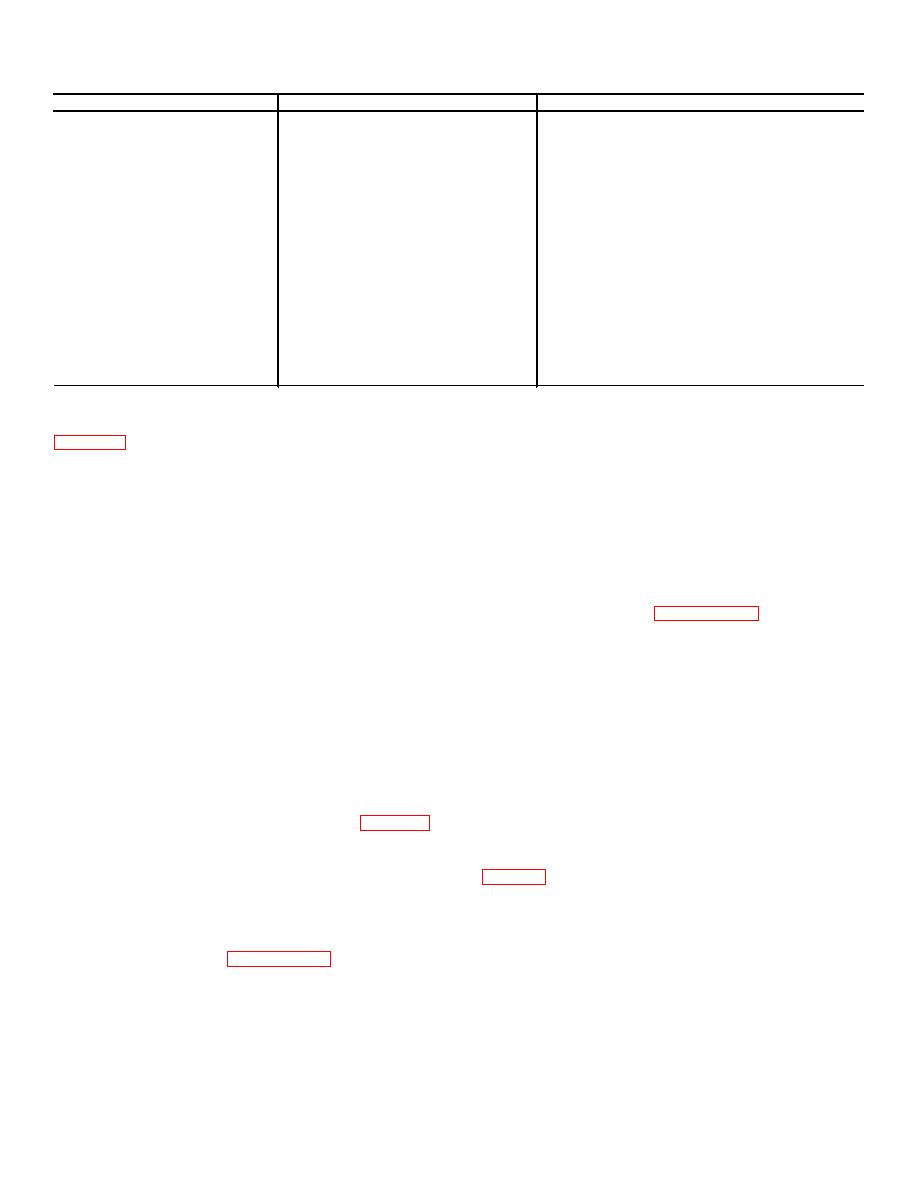

Table 11-2. Operator's Troubleshooting Chart - Liquid Loading System.

Malfunction

Probable cause

Corrective action

a.

a.

1. Engine will not start.

Ignition switch not at ON position.

Place ignition switch to ON position.

b.

b.

Low fuel level.

Fill tank with fresh fuel/oil mixture.

c.

c.

Choke or throttle not set properly.

Adjust choke or throttle as required.

d.

d.

Loosen cap or clean vent.

Gas cap vent plugged.

e.

Vacuum in gas tank.

e.

Loosen cap.

a.

a.

2. Engine not running properly.

Low fuel level.

Fill tank with fresh fuel/oil mixture.

b.

b.

Gas cap vent plugged.

Loosen cap or clean vent.

c.

Air filter dirty.

c.

Clean air filter.

d.

d.

Choked engine.

Push choke in.

3. Pump not pumping.

a. Pump not primed.

a. Fill pump with water.

b. Loose intake line connections.

b. Tighten intake line connections.

c. Pump plugged with contaminant.

c. Stop engine; drain pump and fill with clear, clean

water.

d. Inlet strainer clogged.

d. Clean strainer.

e. Open inlet valve.

e. Input valve closed (handle across tube).

f. Supply fluid depleted.

f. Change supply drums.

g. Pump defective.

g. Refer to organizational maintenance level.

e. Throttle Rod Friction. If throttle rod (28, fig. 11-

(2) Clean the air cleaner element as follows

19) slips or "walks" during engine operation, tighten as

(a) Loosen captive nut (1) and remove

follows:

air cleaner element cover (2). Do not remove nut from

(1) Position ignition switch at OFF to stop

cover.

engine.

(2) Tighten two screws (34) as required to

CAUTION

increase friction of throttle rod clamp (29).

Use care not to allow loose dirt or

(3) Resume normal operation.

dust particles to fall into carburetor

f.

Pump Priming. Since the fluid being pumped

chamber.

lubricates the pump and keeps it cool, make sure the

(b) Before removing air cleaner element

pump contains water or the pumped fluid at all times

(3), remove all loose dirt or dust particles. Then remove

while running. Refer to paragraph 2-1, step b (5) for

air cleaner element.

pump priming procedure.

(c) Slosh the element in clean solvent

g. Inlet Strainer, Hoses, and Couplings.

(not fuel mix), and dry thoroughly before use. If cleaning

WARNING

with solvent is not possible, clean the element by tapping

Insecticide

spray

fluids

are

against a flat surface or by blowing out dust or dirt with

poisonous and should be handled

an air hose.

(d) Replace element after 100 hours of

with care. Avoid splashing fluid or

operation or when it appears clogged and cleaning will

prolonged contact or breathing of

not restore engine power.

fumes. Wash hands before smoking

(e) Install air cleaner element, and

or

eating,

after

contact

with

secure in position with air cleaner element cover and

insecticide fluid.

captive nut.

Prior to operating the equipment, inspect the inlet

c. Fuel Line. Inspect the fuel line (5 fig. 11-2)

strainer, hoses, and couplings for condition and

prior to use, and while engine is running. Observe for

serviceability.

fuel leakage caused by cracked hose or loose

(1) Strainer. Loosen the screw assembly (2,

connections. Stop pump right away if a leak occurs.

Secure loose connections prior to restarting.

(5), and screen (6). Clean the screen by sloshing in

d. Fuel Mixture and Level. Check fuel level prior

clean, running water. Inspect the O-ring, and replace if

to starting pump engine, and fill upon completion of

defective.

operations to prevent moisture condensation in fuel tank.

(2) Hoses. Inspect the hose assemblies for

breaks, cracks, or loose connections. Replace any hose

that proper fuel mixture is used to prevent engine

assembly found to be defective.

malfunctions.

11-6