lers and nipples (4 and 5, fig. 11-1) for condition and

foreign particles which may cause leakage past sealing

cleanliness. Internal sealing valves must be closed when

valves.

h. Ignition Cable. Check ignition cable prior to

coupling halves are separated. Make sure coupling

halves are fully engaged and locked when connected.

starting engine to insure that connections are tight and

Keep dust caps or dust plugs in place when couplers are

that insulation is not cracked or shorted out.

separated. Remove any

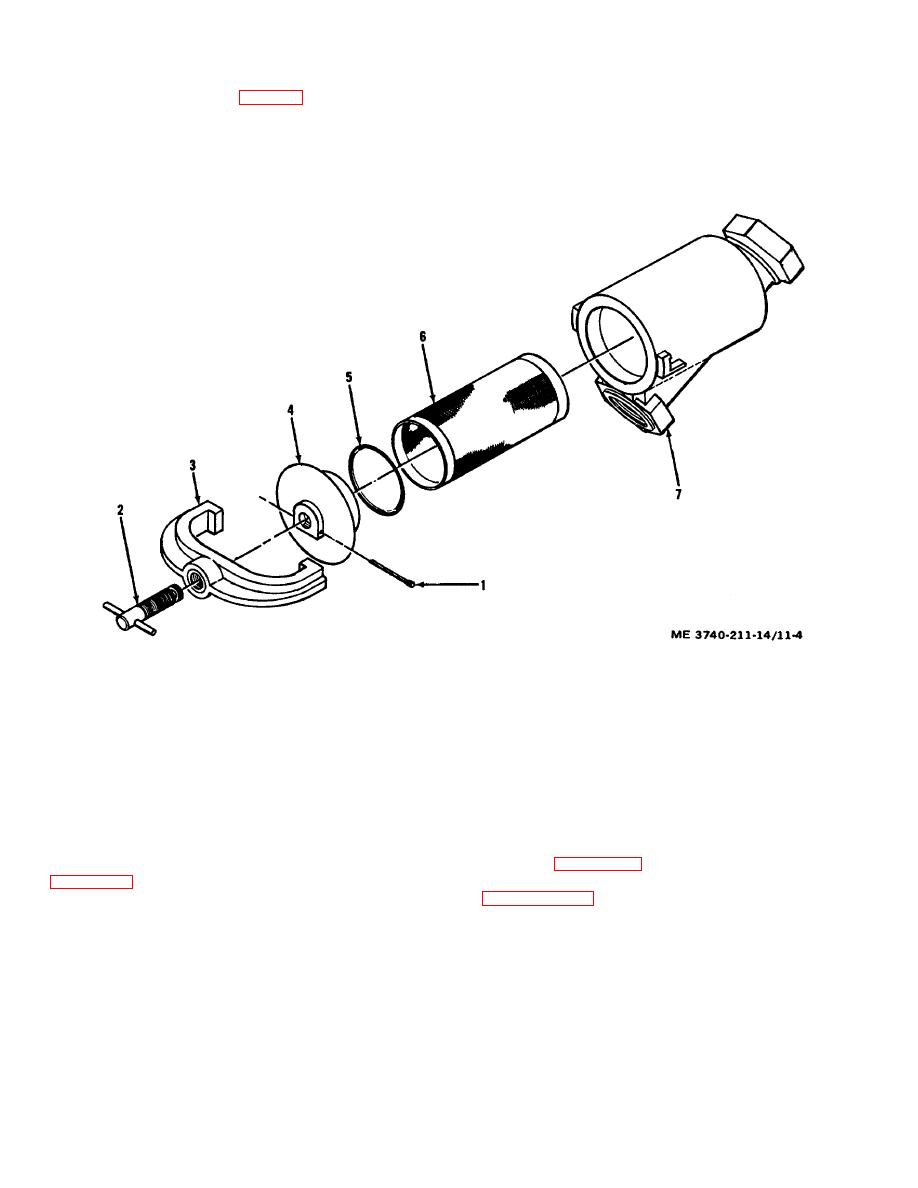

1. Cotter pin

3. Yoke

5. O-ring

7. Body

2. Screw assembly

4. Cap

6. Screen

Figure 11-4. Inlet strainer - exploded view.

Section III. ORGANIZATIONAL MAINTENANCE INSTURCTIONS

special tool required for organizational maintenance

11-6.

Repair Parts, Special Tools, and Equipment

personnel for maintenance of the liquid loading system is

a. Tools and Equipment. Tools, equipment, and

a muffler cleaning tool. This tool can be fabricated as

spare parts issued with or authorized for the liquid

shown in figure 11-5. The tool is used to clean out

loading system are listed in the basic issue items list,

clogged perforations of the muffler as described in

b. Special Tools and Equipment. The only

11-7