Section IV. DIRECT SUPPORT AND GENERAL SUPPORT

MAINTENANCE INSTRUCTIONS

plies normally available to using organizations.

11-9.

General

a. Scope. These instructions are published for the

lists

manufacturer's

sizes,

tolerances,

desired

use of direct support and general support maintenance

clearances, and maximum allowable wear and

personnel maintaining the liquid loading system. They

clearances pertaining to the liquid loading system pump

provide information on the maintenance of the equipment

engine.

which is beyond the scope of tools, equipment,

personnel, or sup-

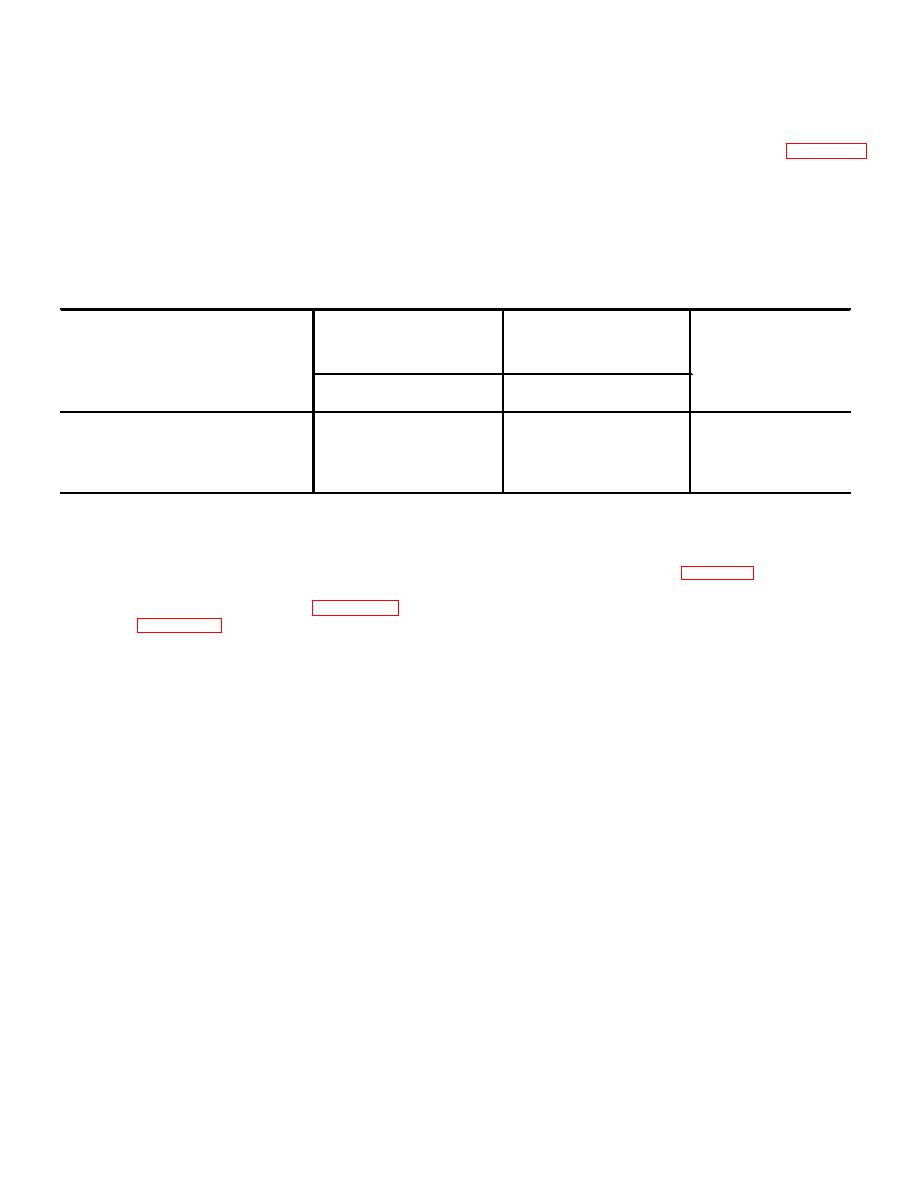

Table 11-5. Repair and Replacement Standards

Manufacturer's

dimensions and

tolerances in

Desired

inches

clearance

Maximum allowable

Component

Minimum

Maximum

Minimum

Maximum

wear and clearance

Crankshaft:

Needle bearing journals

0.6245

0.6250

0.0005

0.0010

0.0005

Connecting rod roller journal

0.5565

0.5570

--------

0.0005

Connecting rod needle bearing journal

0.5615

0.5625

--------

0.0010

for direct and general support maintenance personnel

11-10.

Special Tools and Equipment

performing major overhaul work on the liquid loading

a. Special Tools and Equipment. No special tools

system pump. Tools listed in table 11-6 are not available

and equipment are required.

for issue, .but can be fabricated by qualified maintenance

b. Specially Designed Tools and Equipment. The

personnel for expedient repair by utilization.

specially designed tools listed in table 11-6 and

illustrated in figures 11-8 through 11-14 are

11-13