Note:

(7) Install spray boom assemblies to tank

installation, using figure 4-2 and the following steps as

Front boom cable passes under pump

guides:

support strut on tank installation (29).

(a) Remove cap (30) from end threads of

1. Insert wire-rope shackle (5) through loop

boom tube.

in end of cable assembly.

(b) Remove plug (31) from end of center

2. Secure wire-rope shackle to holes in

section boom on tank installation (29).

end of lower channel rail of tank installation (29) with

(c) Lightly lubricate threads on connector of

screw (4), washer (3), and nut (2).

(h Make sure rear boom cables have slack.

spray boom tube with suitable thread lubricate.

(d) Attach boom tube to center section boom

Tighten turnbuckle on inboard forward cable until tip

with nozzles aft. Tighten boom attaching nut handtight

of boom is about 3 inches forward of boom centerline.

only at this time.

Then tighten turnbuckle on inboard rear cable to

(e) Attach boom support strut (15), with rivet

adjust boom back to centerline position.

(i) Repeat the process of step (h) preceding

heads up, to inboard tube clamp of spray boom

for outboard cables, except reduce boom deflection for

assembly (19).

Secure with clevis bolt (14), washer

this step to 2 inches.

(13), and nut (12). Attach other end of strut to lower hole

(j) Firmly tighten boom tube to boom center

in end bracket located at upper end of tank installation

(29). Secure with screw (11), washer (10), and nut (9).

section. Hold boom tube securely with strap wrench,

(f) Attach upper boom cable of spray boom

while tightening boom attaching nut.

(k) Check to see if boom tubes are straight.

assembly (19) to upper hole in tank end bracket of tank

installation (29). Secure with screw (8), washer (7), and

If not, repeat preceding steps as required.

(l) Upon completion of cable adjustment, if

nut (6).

(g) Attach front and rear boom cables of

available, use MS 21256 lock clips to secure turnbuckles

spray boom assembly (19) to tank installation as follows:

or 0. 041-inch diameter stainless steel lockwire (1, fig.

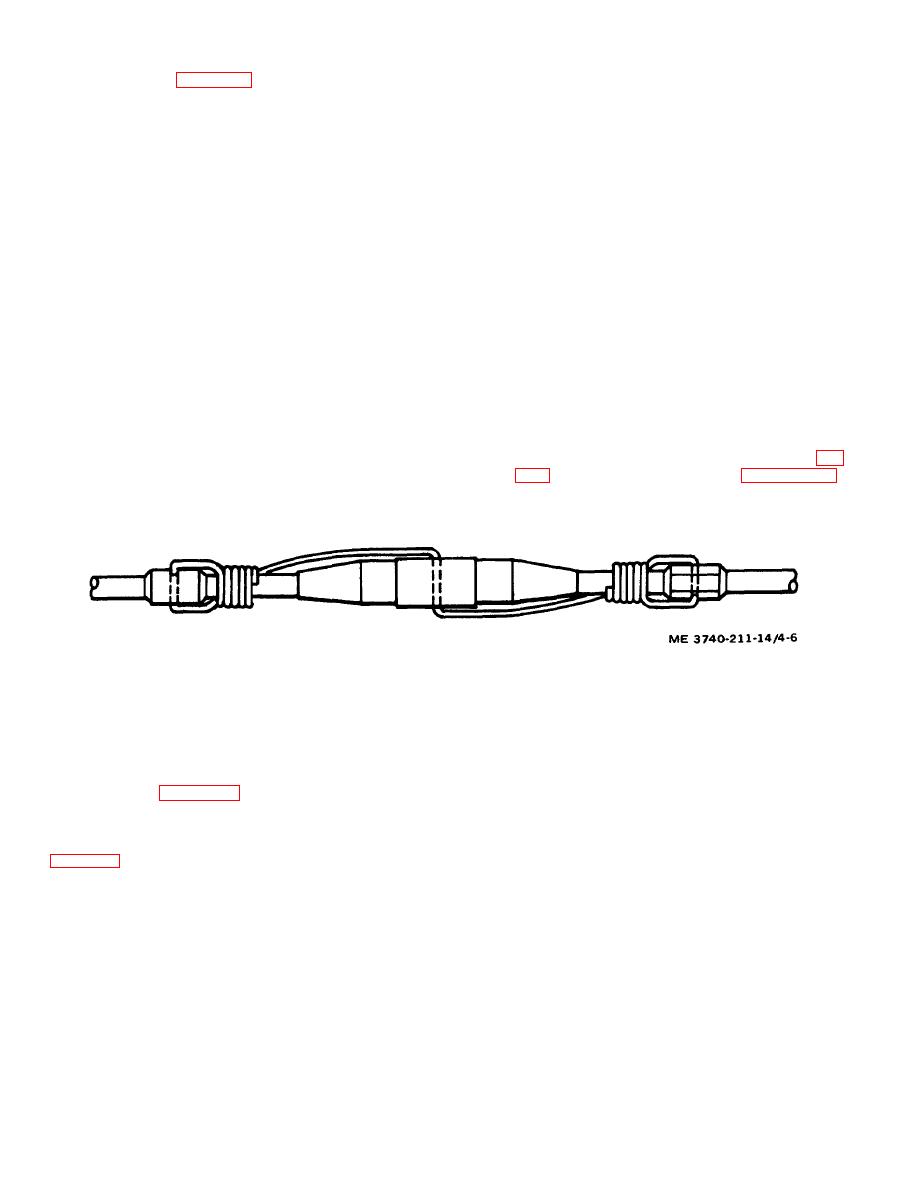

Attach lockwire per figure 4-6, in

accordance with MS 33540.

Figure 4-6. Turnbuckle safetying diagram.

(2) Remove spray boom assemblies as follows:

4-4. Removal from Helicopter

(a) Support spray boom assembly (19) to

a. Usage of the insecticide sprayer is such that it

prevent damage.

normally is removed from the helicopter immediately

(b) Remove lockwire (1) or clips from all

after use. Removal consists of thoroughly flushing and

turnbuckles. Loosen turnbuckles as needed to provide

cleaning the system, as well as removal from the

cable slack.

helicopter. Use figure 4-2 and the following steps as

Note:

guides:

Retain all attaching hardware by replacing in

(1) Thoroughly drain and clean the tank and all

attachment points from which removed.

fluid lines as described in the post flight operation (ref

(c) Remove nuts (2), washers (3), and

screws (4), retaining wire-rope shackles (5) to tank

Use noncorrosive mineral oil following use of oil-

installation (29). Remove wire-rope shackles from front

base spray fluid. Use water following use of water-

and rear boom cable assemblies of spray boom

base spray fluid. Use the liquid loading system for this

assembly (19).

operation to clean that system at the same time.

4-10