TM 55-6610-247-40

z. Changing length of calibration arm causes change

a plus error. turn screw out: to correct a

minus error, turn screw in. Each

in speed of rotation throughout range. Adjustment of

revolution of screw will correct an error

calibration arm speeds up or slows down mechanism

of approximately 80 feet.

throughout entire range. See figure 2-9.

NOTE

Check points listed in table 23 are

primary check points to be used during

position error adjustments.

x. Either change of diaphragm position or change in

length of calibration arm speeds up or slows down

mechanism with corresponding in crease or decrease in

rate of hand rotation between zero and maximum

altitude.

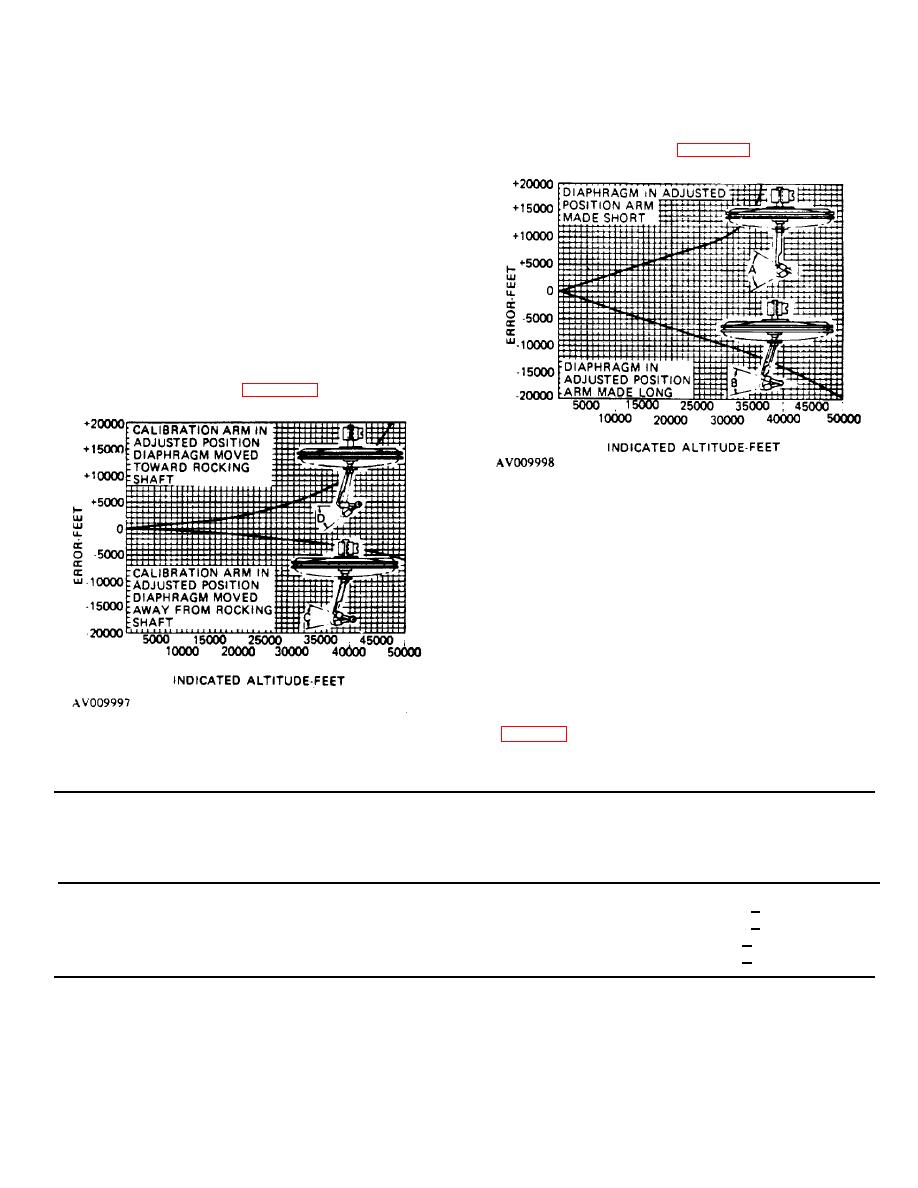

y. Shifting diaphragm position changes speed of

rotation at high altitudes more than at low altitudes.

Shifting diaphragm toward rocking shaft speeds tip

mechanism while shifting it away from rocking shaft

slows down mechanism. See figure 2-8.

Figure 2-9. Effect of Calibration Arm Movement

on Error-feet Range.

aa. By a combination of both adjustments. speed of

rotation can be selectivelv increased or decreased in low,

middle, or high altitude ranges.

ab. The following ratios may be applied when shifting

calibration arm or diaphragm in relation to correction

obtained in instrument indication. Ratios are approximate

but ",ill help in adjusting procedure. Figures for calibration

arm are based on a final change in reading of instrument

caused by turning drum of vernier calibration tool. part

no. TE 639, one segment. Figures for diaphragm are

based on a final change in reading of instrument for initial

change in reading. caused by moving diaphragm. Refer

Figure 2-8. Effect of Diaphragm Movement on

to table 2-4.

Error-feet Range.

Table 2-3. Check Points

STANDARD

EQUIVALENT

SCALE ERROR

ALTITUDES

ATMOSPHERIC PRESSURE

TOLERANCE

MERCURY

FEET

MM

INCHES

FEET

0

760.0

29.92

+20

5,000

632.4

24.89

+40

20,000

349.1

13.75

+130

35,000

178.7

7.04

+350

2-13