TM 55-6610-247-40

permit arm to be moved and turn vernier drum clockwise.

Rim of drum pushes calibration arm n to rocking shaft.

When drum is turned the distance between two

graduations, it moves arm sufficiently to change altimeter

reading approximately 20 feet at 5,000 feet altitude. After

adjusting length of calibration arm, tighten adjusting

clamp screws and remove calibration tool from rocking

shaft. To move calibration arm out of rocking shaft. turn

drum of calibration tool counterclockwise while gently

pressing end of calibration arm with finger to keep arm in

contact with drum. When altimeter mechanism reading

agrees with that of master altimeter or barometer at 0

and 5.000 feet. slowly reduce pressure until master

altimeter indicates 20,000 feet and record indication of

test altimeter. Reduce pressure to maximum range of

instrument and note indication.

e. If mechanism indicates a reading above or below

that of master altimeter, remove mechanism and

adjust position of diaphragm in mechanism body. If

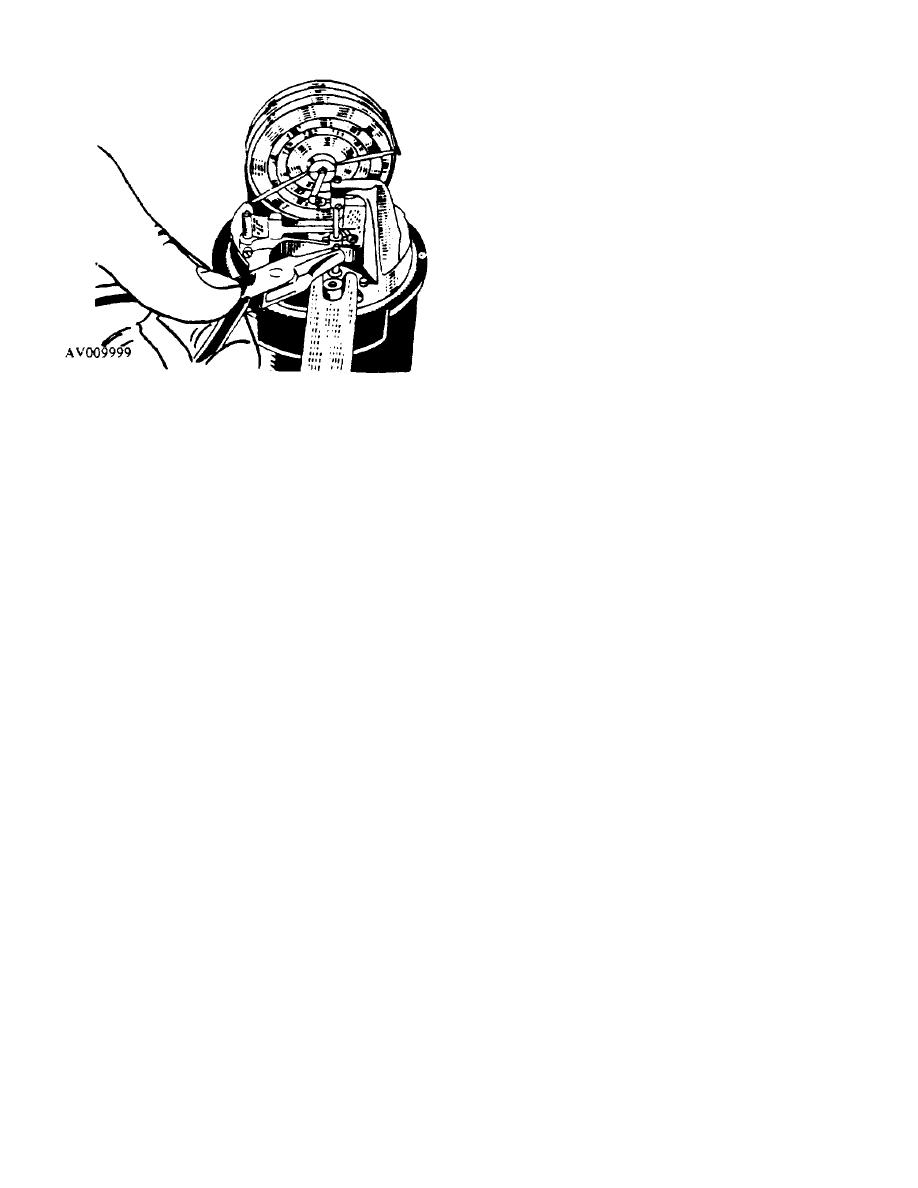

Figure 2-10. Shifting Sector of Rocking Shaft.

mechanism reading is too high, move diaphragm out

away from the rocking shaft). Position of diaphragm may

NOTE

be accurately adjusted with diaphragm calibrating tool,

If hands of master altimeter are below 0,

part no. TE5196. Screw end of tool into diaphragm

close chamber and reduce pressure

centerpiece. Turn large adjustment knob clockwise until

until hands indicate 0. Note position of

sleeve contacts castings. Loosen diaphragm clamping

hand of test instrument. If hand is not on

screw in mechanism body. To move diaphragm toward

0. open chamber to atmosphere and

rocking shaft. turn adjustment knob counterclockwise. To

turn adjustment knob to reposition hand.

move diaphragm away from rocking shaft, turn

Repeat procedure until hands of both

adjustment knob clock wise. Tighten diaphragm clamping

instruments indicate 0 simultaneously. If

screw and remove tool.

hands of master altimeter are above 0,

CAUTION

procedure is similar to that described

The extent that diaphragm may be

above, except instruments must be

moved toward rocking shaft is limited

subjected to pressure.

by balance arm. Do not move

b. Close pressure chamber and slowly decrease

diaphragm too far toward rocking

pressure until master altimeter or barometer indicates

shaft or its expansion in high ranges

a reading equivalent to 5,000 feet.

c. If mechanism shows a plus or minus indication.

will be stopped by balance arm.

f. Shifting diaphragm to correct indication at

remove it and adjust effective length of calibration arm to

which diaphragm link is connected. If mechanism reading

maximum altitude alters both 0 position and setting at

is too high. move calibration arm out of rocking shaft. If

5,000 feet. therefore, mechanism must be adjusted again

mechanism reading is too low, move calibration arm into

so it indicates 0 and 5,000 feet in accordance with

rocking shaft. For accurate adjustment of calibration

preceding steps.

arm, use vernier calibration tool, part no. TE639. Clamp

g. Further adjustment of mechanism should be made

tool onto rocking shaft in highest possible position so

as required until readings come within tolerances

drum rides against end of calibration arm. Then tighten

specified in table 26.

clamp screw.

h. Check backward movement of mechanism by

NOTE

slowly increasing pressure until altimeter indicates a

Clamp screw and screwdrive; should be

minimum of 1,500 feet. maximum of 2.300 feet. Sector

in exact alignment with calibration arm

must be shift with special pliers and wrench as described

before screw is tightened. If not,

in paragraph 28, until above condition exists. See figure

calibration tool will not be correctly

210.

aligned to give accurate adjustment.

d. To move calibration arm into rocking shaft, loosen

adjusting clamp screw just enough to

2-15