TM 55-6610-247-40

cold bath for five minutes. Tap frame lightly and record

in same direction. A turn of the diaphragm support nut

the reading. Any reading other than 0 is an error.

results in a correction of 10 feet.

NOTE

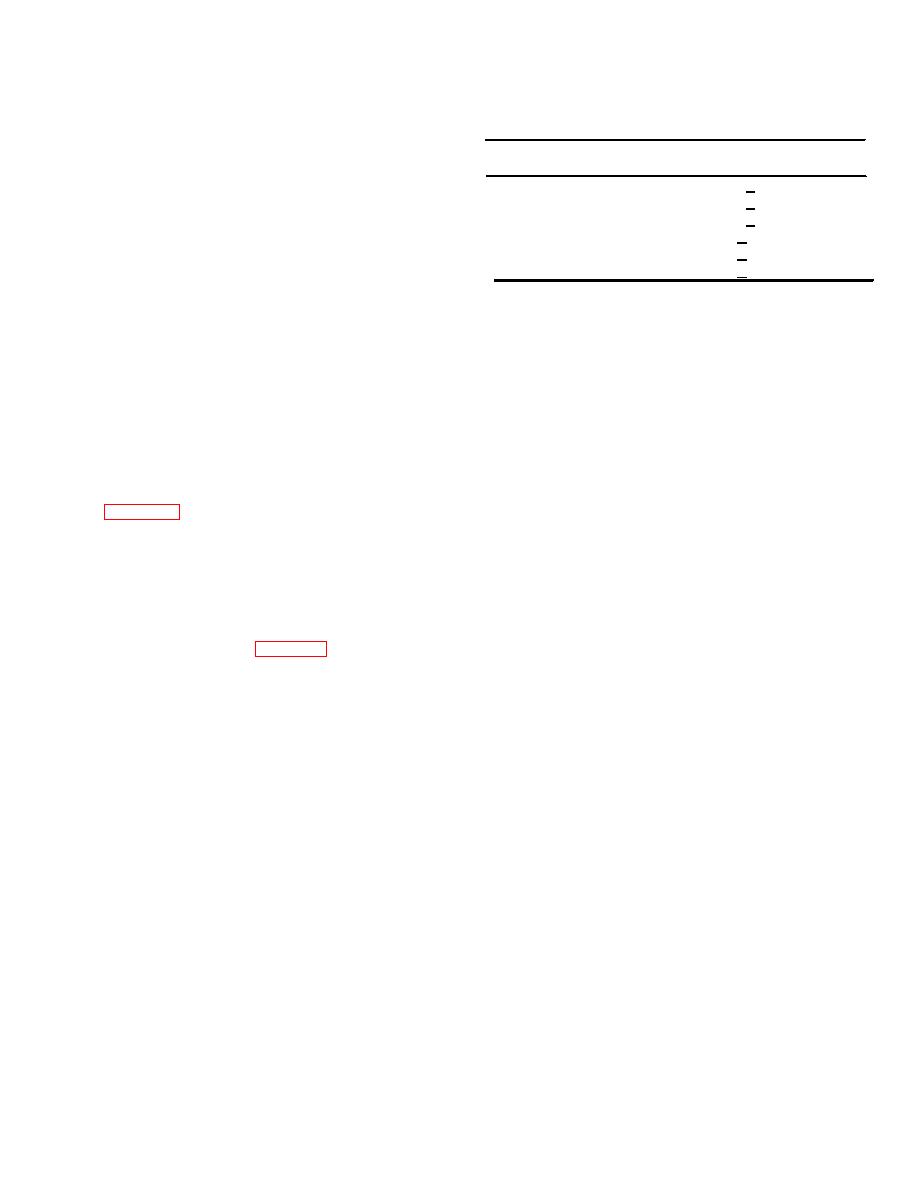

Table 2-2. Progression of Error

Agitate liquid before taking reading.

ALTITUDE

ALLOWABLE CHANGE

When tapping mechanism, strokes

IN FEET

OF READING IN FEET

should be made vertically. Horizontal

0

+30

tapping may move mechanism sideways

6,000

+50

and so shift sector position.

12,000

+80

CAUTION

18,000

+120

To avoid cracking jewels, allow

25,000

+155

mechanism to warm up at room

35,000

+205

temperature. This is best done by

u. When hot bath reading is 50 feet or more below

immersing mechanism in a bath at

cold bath reading, move each push rod to next notch in

room temperature before placing It in

compensator bracket, away from diaphragm.

hot bath.

v. If original hot bath reading is less than 50 feet

below cold bath reading pr when remaining error after

p. Remove mechanism, reset to 0 and immerse in

shifting push rods is still less than cold bath reading, turn

hot bath for five minutes. Tap frame again and record

diaphragm support nut between compensator bracket

reading.

and diaphragm, then turn second diaphragm support nut

q. If reading in hot bath does not differ from reading

in same direction.

in cold bath by more than tolerances specified in table 2-

w. When temperature compensation is completed, if

1, the temperature compensation is satisfactory and no

altimeter was placed in a liquid bath, disassemble

further adjustment is required.

mechanism and clean all parts thoroughly to remove film

NOTE

of oil, paying particular attention to hairspring.

NOTE

throughout range of an instrument with

Use of adjustable centerpiece on current

maximum allowable error at zero feet

altimeters

has

greatly

simplified

altitude: therefore, to maintain a

compensation adjustments.

New

minimum error at various altitudes, it is

centerpiece is made of beryllium copper

important to compensate diaphragm as

which is a harder material than was

near to zero error as possible.

formerly used on the old type

r. If difference in hot and cold bath readings

centerpiece and insures a more friction-

exceeds tolerance shown in table 2-1, adjustment of

free bearing surface for compensator

temperature compensator is necessary.

pins.

Compensation procedure is

s. When hot bath reading is greater than cold bath

basically the same, except now close

reading by 50 feet or more, move both push rods (pins)

adjustments are made with adjusting

between diaphragm. Move rods, one at a time, by

screw on centerpiece instead of two

grasping compensator bracket with tweezers and

locknuts which were formerly used. A

twisting lightly to spring bracket away from end of rod

rough compensation may be obtained by

while shifting rod by grasping it with another tweezer. A

positioning compensating pins

in

movement of one notch gives a correction of from 50 to

dimples of compensator. Each dimple

65 feet in the reading.

will correct an error of approximately 60

t. When original hot bath reading is less than 50 feet

feet.

By increasing angle between

above cold bath reading or when remaining error after

compensating pins and centerpiece, a

shifting push rods is still clockwise, giving a reading that

plus error can be corrected. Conversely,

is too high, turn diaphragm support nut between

a lesser angle will correct a minus error.

compensator bracket and mechanism body so it moves

If distance between dimples is too great

away from diaphragm. Turn second diaphragm support

and does not permit satisfactory

nut between compensator bracket and diaphragm

compensation, it may be further adjusted

by turning screw on centerpiece. To

correct

2-12