Description

Vibration Table Setting With Ambient

Part No.

Temperature at 75 50F

Vacuum Pump-Dual-

1400B (W. M. Welch,

Velocity

Seal

Chicago, Ill.) (or equal)

(In./Sec/Rms)

Frequency (cps)

Bell Jar 6-1/2 x 11 in.

95460 (Corning Glass,

2.0

*15

Corning, N. Y.) (or equal)

2.0

*30

Variable Transformer,

V-10 (General Radio Co.

2.0

50

130V, 60 cycle

Cambridge, Mass.)

2.0

100

(or equal)

1.0

250

0.5

500

Vibration Control

28024-B-2 (Consolidated

0.25

*1,000

Electrodynamics)

0.25

*1,500

Taper Plug

28024-AE-3 (Consolidate

*Not required for Type 4-118-0107.

Electrodynamics)

Straight Plug

28024-AE-4 (Consolidate

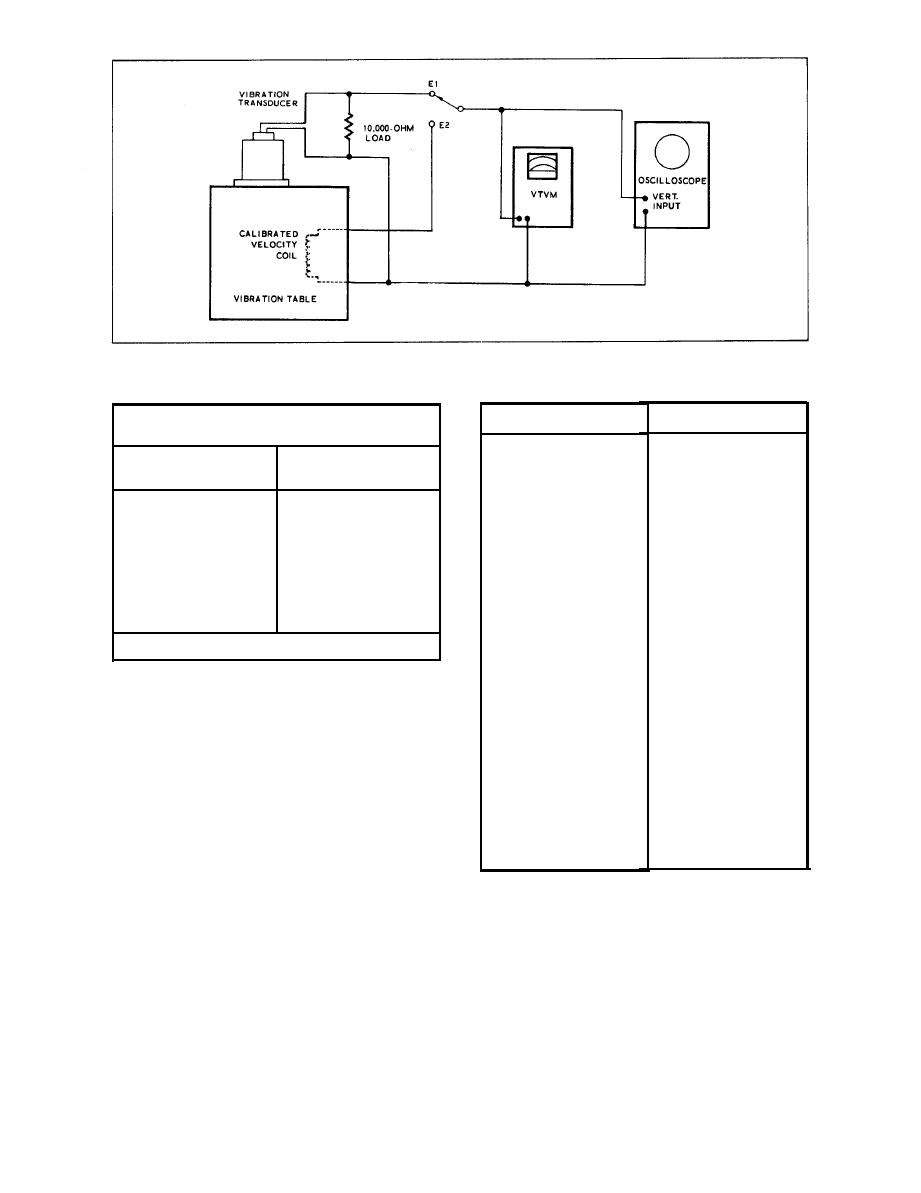

Figure 1-35. Transducer Sensitivity Test Data

Electrodynamics)

Button Setting Plug

28024-AE-5 (Consolidate

(2) Connect a 130V, 60 cycle, variable trans-

Electrodynamics)

former to Knockdown Coil Part No. 28024-AE-8.

Holding Fixture

NOTE

28024-AE-6 (Consolidate

Electrodynamics)

The velocity vibration transducer assembly

Spanner Wrench

28024-AE-7 (Consolidate

operates with a 10,000 ohms resistance load.

Electrodynamics)

(3) Set the variable transformer for 30V ac out-

Knockdown Coil, AC

28024-AE-8 (Consolidate

put, and within 5 seconds manually pass the knock-

Electrodynamics)

down coil over the velocity vibration transducer as-

s e m b l y until it is totally enclosed. Remove the

knockdown coil and again note the output voltage.

NOTE

Required for Overhaul of the Vibration

Transducer Type 4-118-0107

Do not turn off the variable transformer when-

ever the knockdown coil is in the vicinity of the

velocity vibration transducer assembly.