TM 55-4920-227-15

connected to a shaft that actuates the control nut and

speed to a minimum, stop the unit and

pivoted strut, which slides the movable varidisc on the

disconnect the power source.

main motor shaft toward its companion disc thus causing

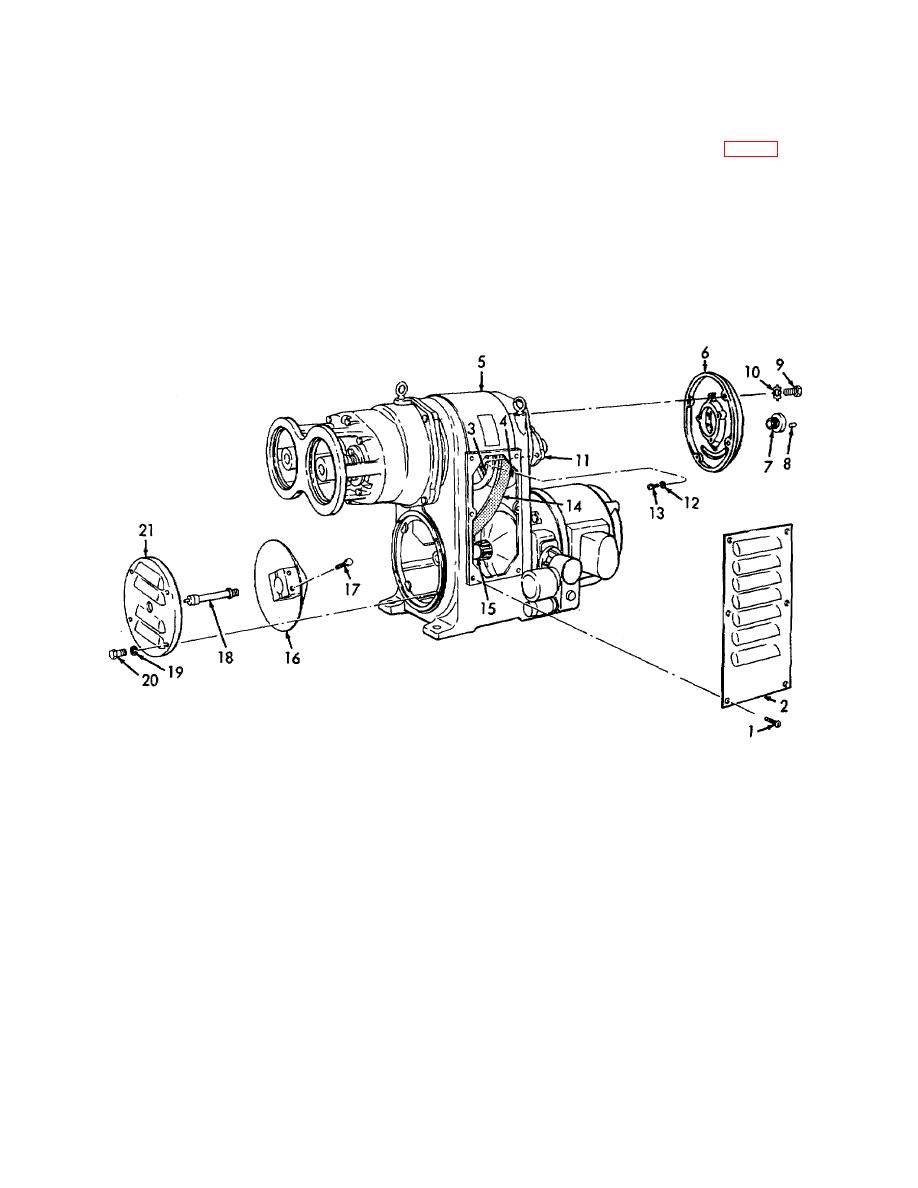

(2) Remove six screws (1, fig. 16) and remove

the varibelt to climb upward on the tapered vaidiscs to a

the louvered cover (2) from each side of the

larger diameter. Simultaneously, the varibelt causes the

case frame (5).

movable varidisc on the driven shaft to retract, permitting

(3) Remove four screws (20) and lockwashers

the varibelt to assume a smaller diameter increasing the

(19) from the end cover (21) and remove the

driven shaft speed, while the main motor speed remains

end cover from the case frame.

constant.

(4) Remove the lubrication extension (18) from

the end of the motor shaft (15).

54. Varibelt Removal and Installation

a. Removal,

(1) Start the test stand and reduce the varidrive

1

Screw (12 rqr)

12

Washer

2

Louvered cover (2 rqr)

13

Screw (3 rqr)

3

Varidisc (Movable)

14

Varibelt

4

Varidisc (Stationary)

15

Motor shaft

5

Case frame

16

Varidisc (Stationary)

6

End cover

17

Screw, cap, hex -hd, 1/2-13 x 2 1/4 in. (4 rqr)

7

Busing retainer nut

18

Lubrication extension

8

Screw (2 rqr)

19

Washer

9

Screw (4 rqr)

20

Screw (4 rqr)

10

Washer (4 rqr)

21

End cover

11

Bearing cap

Figure 16. Varibelt removal and installation.

AGO 6729A

28