TM 55-6680-234-40

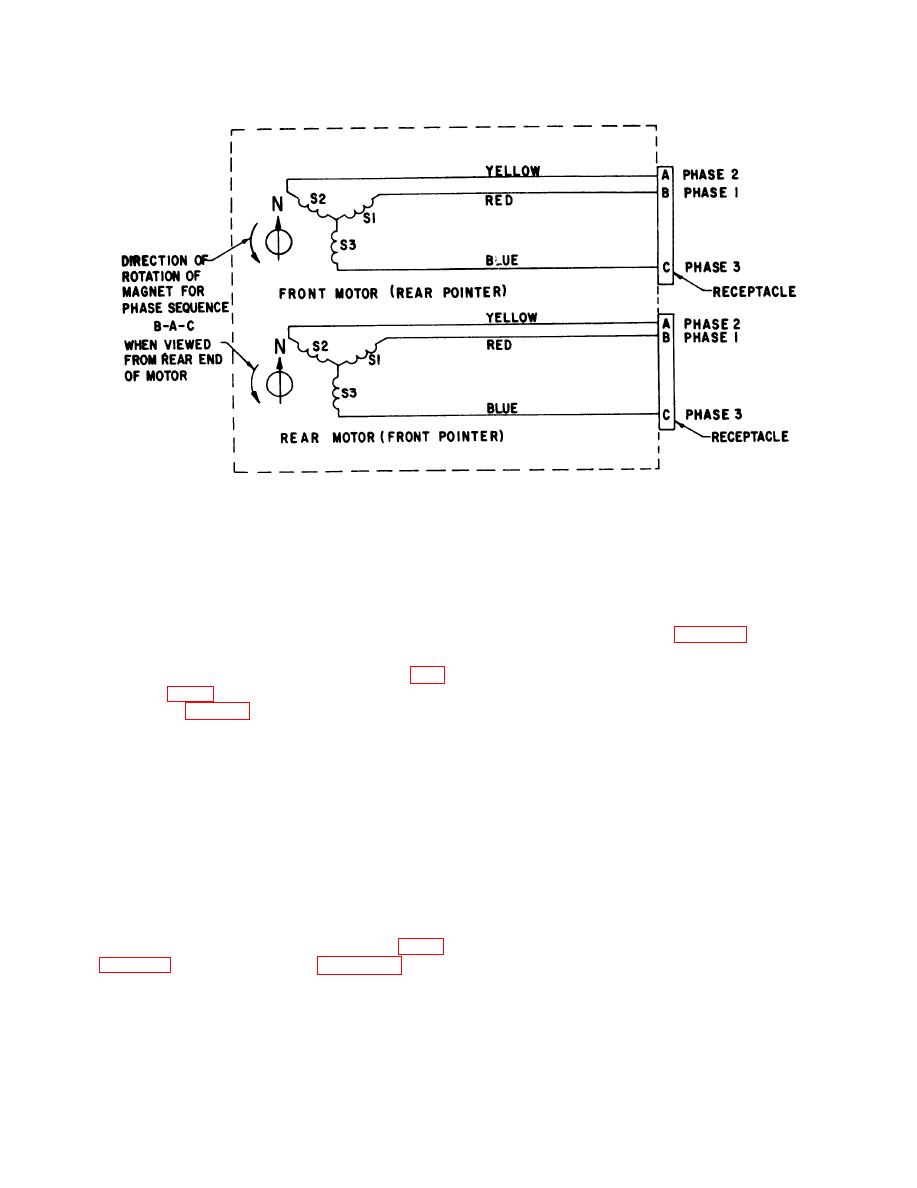

Figure 6. Wiring Diagram

lies in the adjustment of the hair-

tain that the return paths and other compo-

spring. Recheck as outlined in g(5)

nents are securely locked in position with pur-

and (6) above. Place mehanism in

ple glyptol.

normal upright operating position

(dial vertical), Balance unit, as nec-

dial spacer (5) assembled mechanism into case

essary, to maintain proper calibration

assembly (4). Install end cover assembly (28)

by adding balance springs (9 of fig-

so centers of two receptacles are on a hori-

zontal line with unit in normal upright oper-

of figure 8).

ating position with polarizing key of each re-

(3) Again place mechanism in the ver-

ceptacle in the 12 o'clock position in its

tical position (dial horizontal) and

opening.

calibrate the rear motor assembly in

a manner similar to the preceding

procedure except as follows: (This

Comp Sn 63, seal end cover (28) to case assembly (4)

motor also must start with applicat-

ion of 150 RPM as in (2) above.)

around end cover (28) and case assembly (4) to pro-

vide a tight seal

Operate indicator generator at 4516

RPM and adjust rear return path

Caution: Avoid excess solder.

to obtain a reading of 340 RPM.

n. Perform scale error, pointer alignment

p. Pressurize indicator to 20 psi and im-

error, friction error, pointer oscillation error,

merse it completely in clear clean alcohol. Any

and position error tests as outlined in para-

bubbles coming from within the use indicate

a leak which must be repaired. Correct any

Procedure. When these tests have been con-

leak by replacing the defective component or

cluded with unit within tolerance, make cer-

by repairing the faulty soldered joint.

16