TM

55-6680-234-40

Wiring Diagram. Note that end cov-

above. Operate indicator generator

er is marked "FM" and "RM" sig-

at 4470 RPM. Adjust return path

nifying front motor and rear mo-

(10 of figure 9) to obtain a read-

tor; attach wires accordingly. Use

ing of 7000 RPM on engine pointer.

solder 63/37 lead-tin mixture.

If necessary, check magnetism of

m. Calibrate the assembled mechanism as

front magnet assembly (1 of figure

follows:

(1) Place mechanism in the vertical posi-

this reading. If magnet assembly re-

tion (dial horizontal). Check align-

quires remagnetization, be certain to

ment of pointers; if necessary, set

submit it to the thermocycle de-

pointers at zero by adjusting hair-

scribed in the note following e

spring plate (16 of figure 8 and 10).

above. Secure return path in posi-

(2) Connect front or engine motor assem-

tion. Check 0, 4000, and 7000 test

bly to indicator generator TTU-25/

E. Rotor assembly must start with

the application of 150 RPM. If not,

to assure that calibration is within

check magnetization of rotor assem-

tolerance. If mechanism is not prop-

bly (14 of figure 9). Refer to f

erly calibrated at this point, the fault

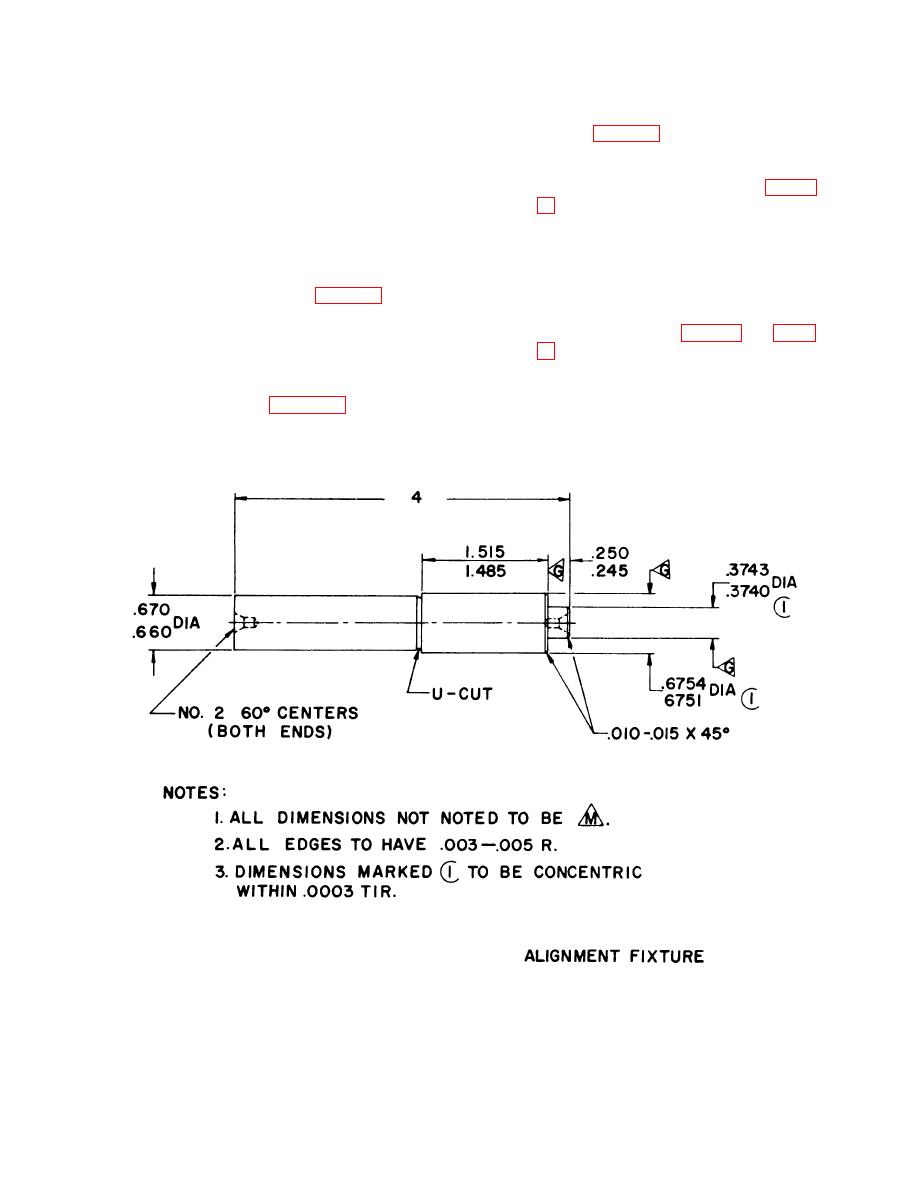

Figure 5. Alignment Fixture.

15