TM 55-6610-247-40

s. Loosen screw 150) and remove jewel setting

modified to a 'D' configuration pointers (16, 17, and 18).

ring (20) and dial (23) shall be discarded

assembly 140).

f. Remove gear assemblies (29, 30 and 31).

NOTE

g. Remove pin (32) and retaining ring (33).

The arm and balance assembly (41)and

h. Before removing top plate mechanism assembly

diaphragm assembly (46) should not be

(34). remove shoulder screws, (3, figure 2-2). Lift off top

removed from mechanism body unless

bearing plate assembly (4) and wheel assembly (10).

they are to be replaced.

i. 'With a pair of parallel jaw pliers, grasp a spoke of

t. Loosen screw (51) and remove arm ,and balance

top plate mechanism assembly (34, figure 2-1) and

assembly (41).

remove it from case (47). Refer to paragraph 2-4 for

u. Loosen screw (52) and remove diaphragm

repair and

replacement procedures of top plate

assembly (46) from body assembly (47).

mechanism assembly (34).

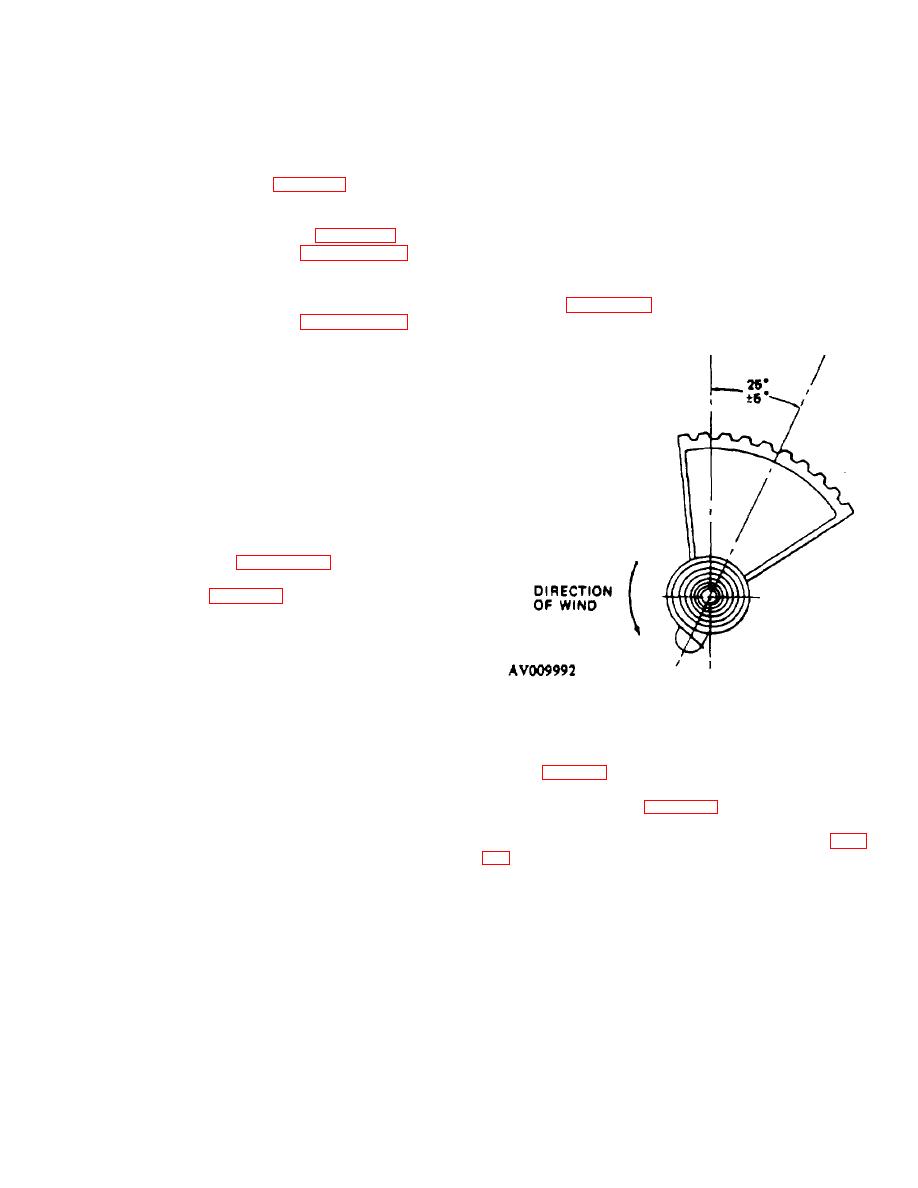

v. Rocking shaft and sector assembly has a strong

j. Grasp a spoke of mechanism assembly (36) and

hairspring. Figure 2-3 shows direction of wind and

remove it from case (47). Refer to paragraph 2-4 for

position of end of hairspring so it will have three-fourths

repair and

replacement procedures for mechanism

to one-turn tension when pinned at assembly.

assemblv (36).

j.l. If installed, remove shim (36A) from the case.

k. Place top plate mechanism assembly (1, figure 2-

21, diaphragm down, in a suitable assembly stand.

CAUTION

Pressure shall be applied evenly as any

side pressure may break hand staff

pinion

I. With back end of a pair of tweezers, press down

on hand staff pinion (14), pressing jewel setting

assembly (13) from mechanism body.

m.

Lift pinion (35, figure 2-11 off top plate

mechanism assembly (34).

n. Remove pin (15, figure 2-2), diaphragm link 16 h,

and calibration arm (17).

o.

Remove pin (42), balance link (44), and

calibration arm 143).

NOTE

Calibration arms II - and 43) should be

left in shaft assembly 120). Move these

Figure 2-3. Direction of Hairspring on Rocking

arms for adjustment and balancing only.

Shaft.

2-2. Cleaning.

p. Remote setscrew (191, then lift shaft assembly

Clean all parts by washing them in clean benzene,

1201 straight up so lower pivot clears jewel. and remove

(item 2, table 1-3), and dry with clean, dry. compressed

it from mechanism through cutout provided in front of

air. Clean pivots by pressing them into end grain of dry

casting.

pithwood (item I 11. table 1-3) and twirling them

q. Remove screws 128) and carefully pry bridge

between fingers. Clean jewels and bearing holes by

assembly 130) from mechanism body. Carefully turn

twirling sharpened end of a pegwood stick (item 12, table

bridge assembly over toward center of mechanism

assembly 1121. Holding bridge assembly firmly at right

with a no. 2 watchmaker's brush dipped in benzene.

angles to mechanism, push tapered pin 42') free with

2-3. Inspection.

pliers.

Inspect as follows:

r. With tweezers inserted through opening in side -if

a. Inspect all gear teeth for wear or damage.

casting. grip pinion of wheel and hair- spring assemble,

b. Inspect jewels for chips or cracks.

(33) and lift it straight up so lower pivot clears jewel (31).

c. All pinions and pivots must be free from

Move wheel and hairspring assembly (33) along channel

in mechanism body and out.

Change 5 2-6