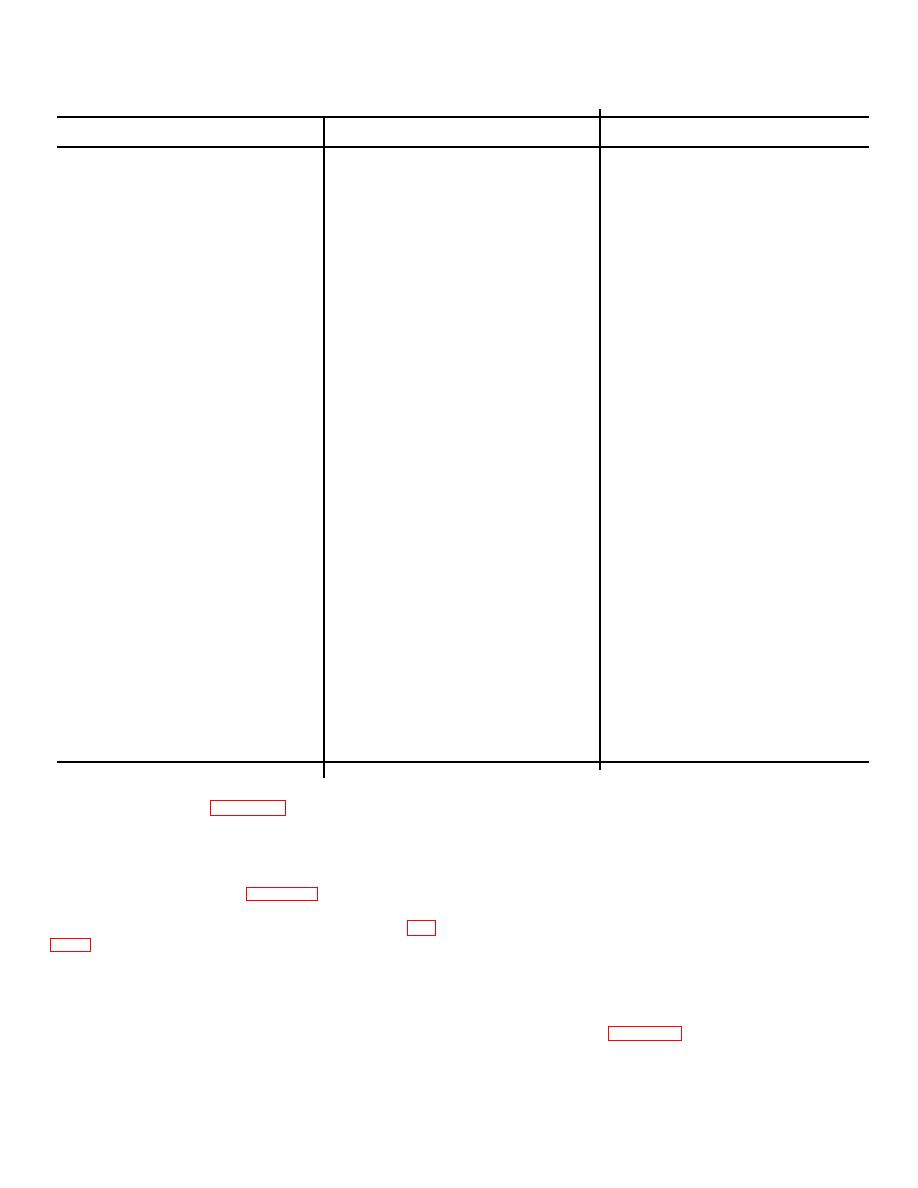

Table 11-7. Direct Support and General Support Troubleshooting Chart -

Liquid Loading System

Malfunction

Probable cause

Corrective action

1. Engine fails to start or starts with dif-

a. Breaker points defective or improperly

a. Regap or replace breaker points (11-

ficulty.

gapped.

13b).

b. Condenser defective.

b. Replace condenser (11-13b).

c. Carburetor dirty or defective.

c. Clean or replace defective carburetor

parts (11-12c).

d. Starter binding or defective

d. Check and correct trouble (11-13a).

e. Spark plug overheated (indicated by

e. Check for:

burned electrode; insulator tip light

1. Clogged muffler (11-&), or

gray or chalk white).

exhaust port or exhaust

manifold (11-8d).

2. Air leak in fuel line (11-5c).

3. Ruptured fuel pump diaphragm

in carburetor (11-13e).

f. Spark plug: wet, fouled indication; in-

f. Check for incorrect carburetor adjust-

sulator tip black, damp oily film over

ment (11-8f); air cleaner element

firing end; carbon layer over entire

clogged (11-5b); wrong fuel mix

nose.

11-5d); faulty ignition parts (11-12d

and 11-13b).

g. Spark plug: oxide fouled indication

g. Check for excessive combustion

(electrode covered with ash-like de-

chamber deposits (11-13d);

posits).

Clogged muffler (11-8c); clogged

cylinder exhaust port

or manifold (11-8d); use of non-

recommended oil, or to much oil in

fuel mix (11-5d).

2. Engine lacks power.

a.

Piston rings worn.

a. Replace piston rings (11-13d).

b.

Cylinder worn or scored.

b. Replace cylinder (11-13d).

c.

Damaged bearings.

c. Replace bearings (11-13d).

d.

Carburetor dirty.

d. Clean or replace defective carburetor

parts (11-13e).

e. Parts binding.

e. Check and replace damaged parts (11-

13d).

f. Damaged or leaking crankcase.

f. Check and correct trouble (11-13d).

3. Engine speed erratic or pump output

a. Parts binding or worn in pump.

a. Check and replace damaged parts (11-

erratic.

12c and 11-13f).

b. Intermittent magneto coil failure.

b. Replace magneto coil (11-12d).

4. Ball valve leaking or will not shut off.

Worn or damaged parts.

Check and replace damaged parts

(11-13g).

5. Couplers leaking or will not engage or

Worn or damaged parts.

Check and replace damaged parts (11-

disengage.

18g).

b. Starter Fan Housing.

connected to the ignition coil (50). Slide the quick-

(1) Removal (fig. 11-15).

disconnect terminal (10) straight onto the coil (50) tab.

(b) Hold the starter fan housing assembly in place

(a) Using a thin-walled 5/16-inch socket wrench or a

with one hand. Pull the starter handle

large screwdriver, remove four housing screws (1 and 2).

(5) out a short distance with the other hand

(b) Lift the starter fan housing and attached parts (3

until the starter fingers engage properly and the fan

through 14) out far enough to clear the end tabs of the

housing seats against the engine.

left and right legs (2 and 5, fig. 11-22). Continue to lift

the starter fan housing out far enough to permit

CAUTION

disconnecting the ignition switch electrical lead (11, fig.

Starter fan housing must seat all

around to avoid breaking of housing

the terminal.

or starter fingers when screws are

(c) Remove starter fan housing assembly from

installed and tightened.

pump engine.

(c) Install and tighten the four screws (1 and 2).

(2) Installation.

Note that lower two screws also secure tabs of right and

(a) Position the starter fan housing assembly (3)

left legs (5 and 2, fig. 11-22) to fan housing. Note also

with attached parts close enough to the engine so that

that the one shorter screw (5/8-in. long) is to be

the ignition switch lead may be

installed in the upper centrally located screw hole.

11-20