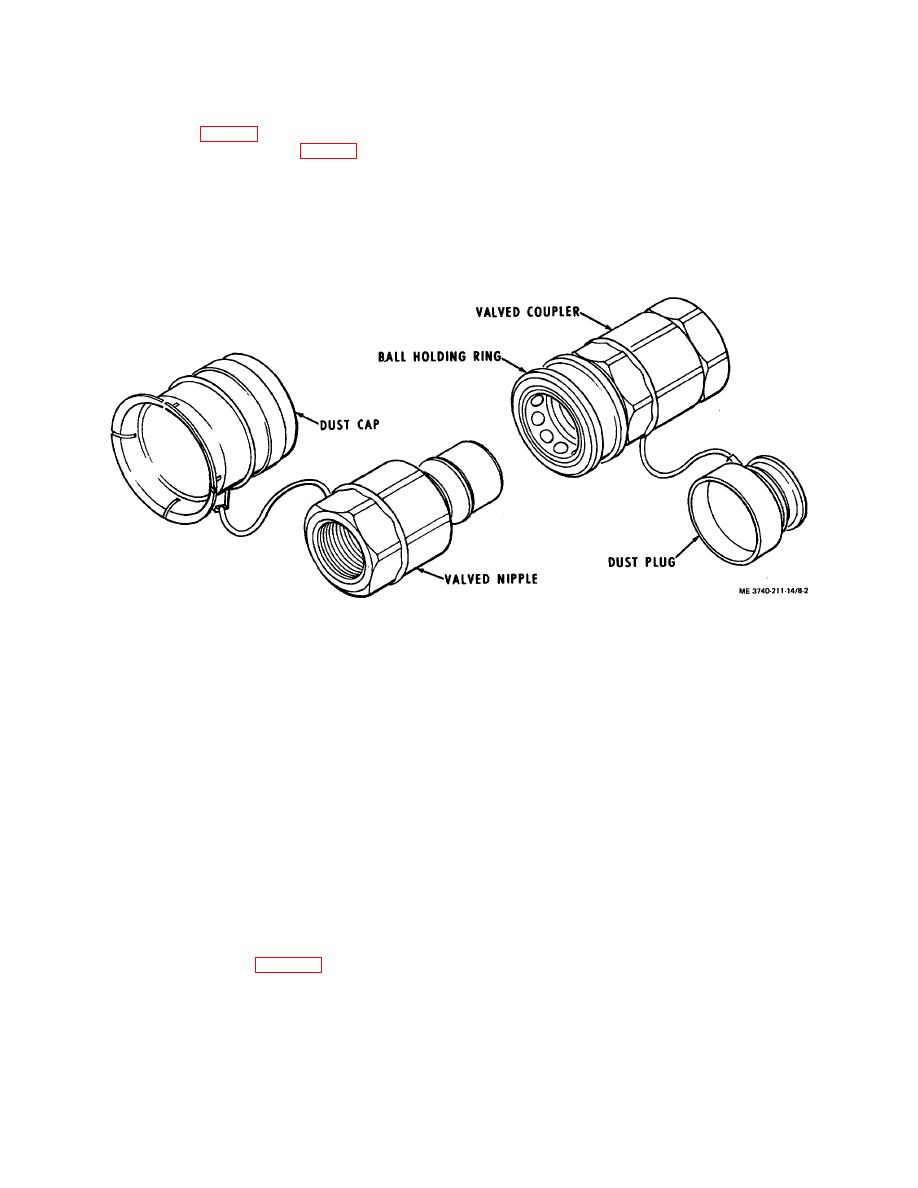

Section II. VALVED QUICK-DISCONNECT COUPLING

balls in the valved coupler half which engage in a groove

8-6. General

on the valved nipple half. The balls are retained in place

by a sleeve on the valved coupler half. Sliding the sleeve

A valved nipple (36, fig. 4-9) is attached to the liquid

away releases the balls, allowing the coupling halves to

loading tube (41). The valved nipple (fig. 8-2) contains a

disengage. When disconnected, springs within each

poppet which is spring-loaded closed against a seat

coupling half return the respective poppets to the closed

within the body. The valved nipple forms the male half of

position. A dust cap and dust cover are attached to the

a quick-disconnect coupling. A valved coupler forms the

valved nipple and valved coupler, respectively, by steel

female half of the quick-disconnect coupling and is part

cables. The dust cap and cover are used to cover the

of the liquid loading system (ch. 11). When the coupling

open ends of the coupler to protect them from dirt,

halves are mated, valves within each half of the coupling

grease, and other contaminants.

force each other open. The coupling is held together by

Figure 8-2. Valved quick-disconnect coupling.

following specific checks:

8-7. Removal

(1) Check threaded parts for crossed or

otherwise damaged threads.

Remove the valved nipple from ground loading tube of

(2) Check condition of teflon seals on valve

the insecticide sprayer as described in paragraph P16,

assemblies for cuts or contamination with foreign

step c.

particles.

(3) Check seating surfaces within nipple and

8-8. Cleaning and Inspection

coupler for nicks, scratches, or other damage.

c. Discard valved nipple or coupler if either is

a. Clean all parts of the valved quick-disconnect

found not to be usable.

coupling thoroughly to remove spray fluid residue, dirt,

lubricants, and other contaminants.

b. Inspect condition of all parts.

Make the

Section III. TANK ASSEMBLY

internal baffles provided for strength and to reduce

8-9. General

sloshing of fluid within the tank during flight. The tank is

translucent with fluid level markings on each end. A fluid

The tank assembly (125, fig. 4-9) consists of a

level gage is mounted on the front side. Fluid level within

cylindrical, molded fiberglass tank with attachment

the tank can be seen through the tank material. In

fittings for components connected to the tank. The tank

addition, connectors for components attached to the tank

has a 200-gallon capacity and is a molded fiberglass

are permanently attached.

reinforced polyester resin structure. It contains two

8-5