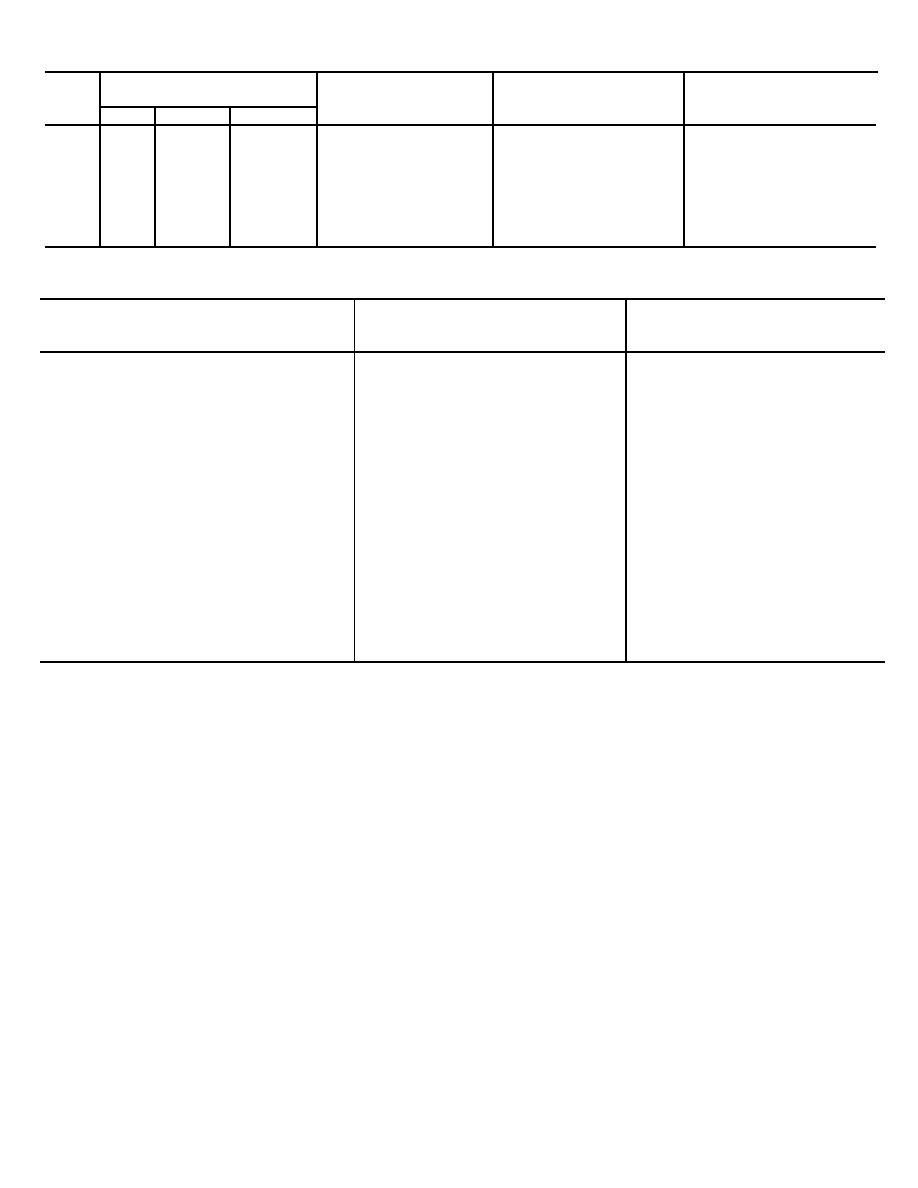

Table 3-1. Operator's Preventive Maintenance Checks and Services.

Item

No.

Daily Interval

Item to be inspected

Procedure

Reference

B

D

A

01

Insecticide sprayer

Perform pre-light check

2-1

02

X

Pump assembly

Do not allow to run dry

2-7c

X

3-3d

2-7e

03

X

Insecticide sprayer

Perform post flight check

1

B = before operation; D = during operation; A = after operation.

Table 3-2. Operator's Troubleshooting Chart.

Malfunction

Probable cause

Corrective action

1. Booms noticeably vibrate or misalign in

Cable tension out of adjustment.

Land aircraft and adjust tension (4-

flight

3a (7)).

2. Leak develops in system during flight.

Faulty fluid system components.

Apply pump brake; stop operations

(2-7d).

3. Use of pump causes vibration.

Fan blade damaged, or pump

Apply pump brake; stop operations

(2-7d).

bearings faulty.

Cancel mission; return to base (2-

4. No response to start spray command.

a. Loose connection or connector on

7d).

control valve.

b. Inlet or outlet couplings split.

Cancel mission; return to base (2-7d).

Stop pump at once using pump

brake(2-7d).

5. No response to stop spray command.

Loose connection or connector on

control valve.

a. Brake cable or cable connector

6. Spray intermittent.

See footnote at end of table.

loose.

b. Faulty windmill drive on pump.

See footnote at end of table.

a. Contamination in spray nozzle.

7. Spray uneven

See footnote at end of table.

b. Faulty pump.

See footnote at end of table.

c. Boom tee strainer clogged.

See footnote at end of table.

For intermittent or uneven spray, record condition for service. Depending upon severity of condition, complete or

discontinue mission.

3-2