T.O. 1-1A-9

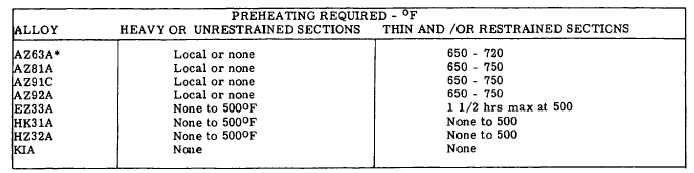

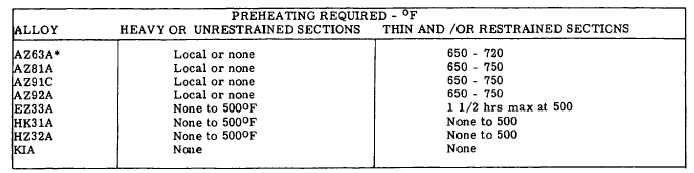

TABLE 4-19. PREHEAT TEMPERATURES FOR WELDING CASTINGS.

Preheat at rate not exceeding 150F/hr from 500F to treating temperature if casting is in -F temper.

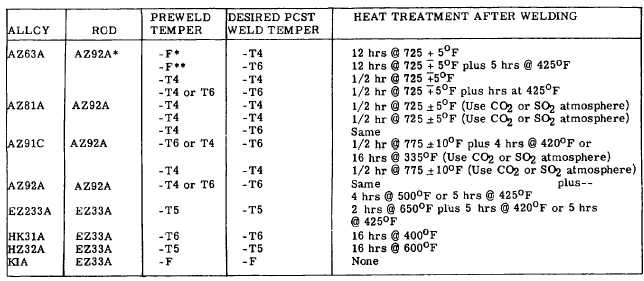

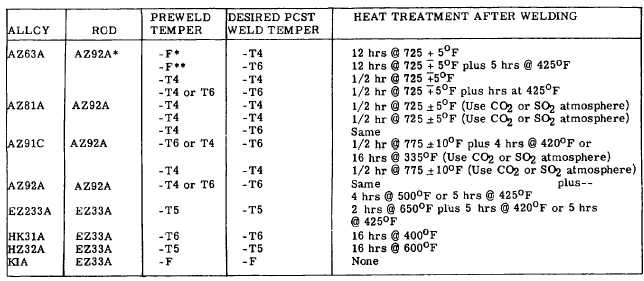

TABLE 4-20. HEAT TREATMENT CASTINGS AFTER WELDING.

UseAZ63A rod if required.

Preheat not exceeding 150F/hr from 500°F - Use AZ63A rod with -F since 12 hrs @ 725F causes germination in

AZ92A welds.

4-73. Welding Methods and Procedures. The following paragraphs will explain the general guidance for manual arc

welding, machine welding and consumable electrode welding. Specific data on alloys should be derived from the use of

applicable specifications for the alloy and for the type welding to be done.

4-74. Prevention or Cracks, Warpage and Stress Corrosion. Cracks sometime occur during welding of some alloys and

can be prevented by one of two methods:

a.

Butt scrap pieces of stock of the dimension and alloy of the material being welded against each end of the joint.

Start the weld in the joint of one scrap piece and continue across onto the opposite scrap piece, welding both scrap and

basic material together for later separation.

b.

Start the weld in the middle of the joint of the material and weld to each edge. No scrap use is necessary here.

Some crack minimization can be gained also if both material and holding fixtures are preheated to 200

400F or by

increasing the speed of the welding.

4-75. Warpage can often be prevented by proper use of jigs or holding fixtures and/or tack welding prior to complete

welding. Tack welds on 0.064" material are 1/16" tacks spaced 1-2 inches apart. On thicker material such as ¼" the

tacks are ¼" 4-5 inches apart. Start the tacks a short distance from the end of the seam. Any straightening of the metal

required from tacking may be done with a soft leather or wood mallet. If work hardening has occurred in apart it may be

corrected by heating the parts at stress relief temperatures and then lightly hammering or pressing it into shape with a

leather or wooden mallet, or by placing the part in the fixture it was welded in and oven heating it to stress relief heat.

Change 13

4-31