T.O. 1-1A-9

3-57. The above are heated by gas, electricity and oil. Regardless of the method utilized it must be demonstrated that

satisfactory results are obtained and the material is not injured.

3-58. AIR FURNACES. Air furnaces are ideal for precipitation (aging), thermal treatments and annealing. These

furnaces are also used for solution heat treating. The initial cost of these type furnaces is higher than for the salt bath

types, but they are usually more economical to operate, safer, cleaner and more flexible. Air furnaces used for heat

treatment of aluminum alloy should be of the re-circulating air type. The heated air in this type furnace is recirculated at

high velocities to obtain a rapid heating cycle and uniform temperatures. The products of combustion must be excluded

from the furnace atmosphere to help avoid high temp oxidation and atmosphere contamination.

3-59. SALT BATHS. The salt baths method has certain advantages over the air furnace. However, the advantages are

usually confined to solution heat treatment only. Associated advantages are uniform temperature without excess danger

of high temperature oxidation and faster heating which reduces the time required to bring the load to temperature.

This method is adaptable for solution heat treating small parts, large thin sections and mixed loads. The above

advantages may be completely nullified by the slower quench caused by the necessary arrangement of equipment, fire

and explosion hazards, and decomposition of the sodium nitrate which when dissolved in quenching water forms a

compound that attacks aluminum alloys. The addition of potassium dichromate (approximately ½ ounce per hundred

pounds of nitrate) tends to inhibit the attach.

3-60. Hollow core casting or parts where the salts are Iikely to be difficult or impossible to remove should not be treated

by bath salt.

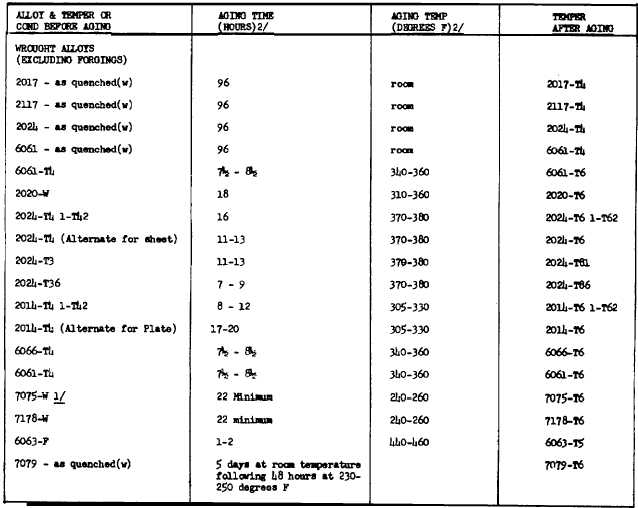

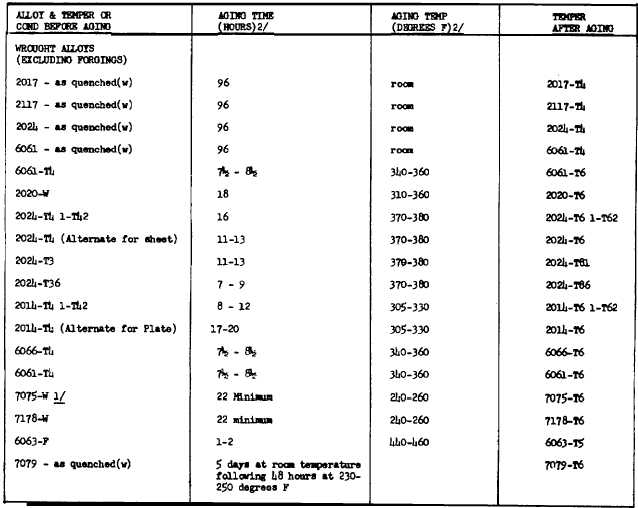

TABLE 3-11. PRECIPITATION (AGING) TREATING TEMPERATURES,TIMES & CONDITIONS.

3-22