T.O. 1-1A-9

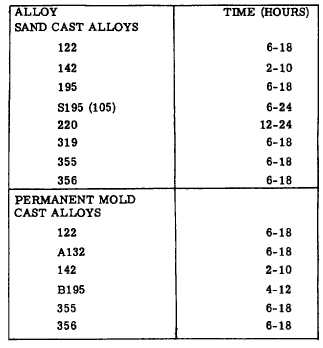

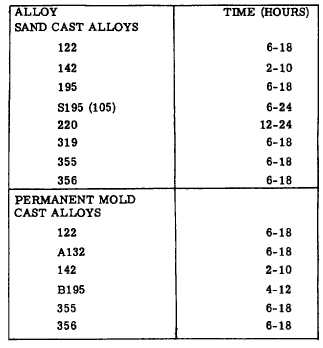

TABLE 3-9. SOAKING TIME FOR SOLUTION

TREATMENT OF CAST ALLOYS.

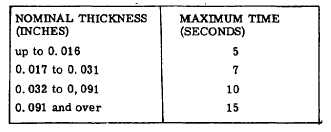

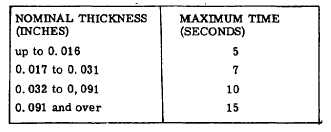

TABLE 3-10. RECOMMENDED MAXIMUM

QUENCH DELAY, WROUGHT ALLOYS (FOR

IMMERSION TYPE QUENCHING).

NOTE

Quench delay time begins at the instant furnace

door begins to open or at the instant any portion of

a load emerges from a salt bath and when last

portion of the load is immersed in the (water)

quench tank. The maximum quench delay may be

exceeded (usually confined to large sections or

loads) if temperature will be above 775° F when

quenched.

3-51. HEAT TREATMENT.

3-52. PRECIPITATION (ARTIFICIAL AGE) HEAT

TREATMENT. Precipitation heat treatment of many

aluminum alloys is necessary to obtain the required

properties. Heating of some aluminum alloys bare or

alclad at an elevated temperature, but well below the

annealing temperature, after solution heat treatment will

result in tensile and yield strength well above those

obtained by room temperature aging. The above will

also apply to alloy 2024. However, this process will

reduce the elongation factor of the material and

increase resistance to forming. Therefore, most forming

operations should be performed prior to this stage of

treatment.

3-53. Mechanical properties obtained from precipitation

(aging) are dependent on the amount of cold work

present in the material at the time of aging. The

selection of materials for various uses will therefore be

governed by the severity of the cold work to be

performed, strength and condition of the material

required.

3-54. Annealing or solution heat treating will remove

any properties developed as a result of cold working the

material. Subsequent heat treatment and aging of

annealed material or aging of solution heat treated

material will result in T-6 condition, provided the

material is Mot cold worked prior to aging. The higher

strength conditions can only be obtained by a controlled

amount of cold work prior to aging. Conditions T-81 or

T-86 would necessitate a cold work percentage of

approximately 1% for T-81 and 6% for T-86 after

solution heat treated and prior to aging.

3-55. Field accomplishment of the cold work required to

produce the higher strength conditions is considered

impractical. This is due to the amount and types of

equipment necessary to stretch or roll the material in

order to produce these conditions.

3-56. HEAT TREATING EQUIPMENT . Equipment and

heating media used are divided into two distinct groups.

They are liquid baths and controlled atmosphere. Either

method has certain advantages over the other and it

generally is advisable to weigh the advantages desired

and consider environmental conditions.

3-21