T.O. 1-1A-9

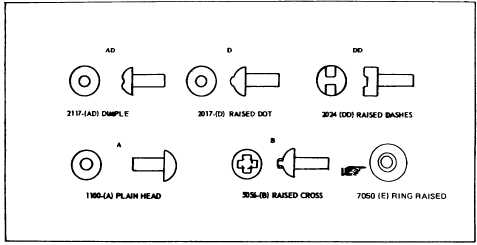

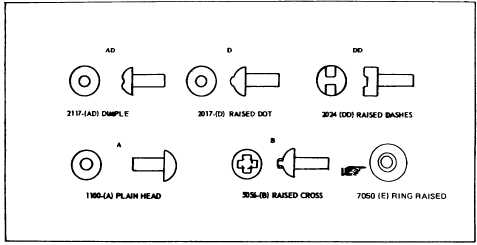

Figure 3-1. Head To Alloy Identification Method

3-37. HEAT TREATMENT OF RIVETS . The heat-treatable alloys commonly used for rivets are 2117, 2017, and 2024.

a. 2117 Rivets. If supplied in T-4 temper no further treatment is required. The rivet is identified by a dimple in the center of

the head (see Figure 3-1-AD for head identification).

b. 2017 or 2017-T4 (D) Rivets. Heat treat prior to installation by heating to 940°F 10°F for 30 minutes in a circulating air

furnace, 1 hour in still air furnace, or 30 minutes in a molten salt bath and quench in water. These rivets must be driven within 20

minutes after quenching or refrigerate at 32°F or lower which will delay the aging time 24 hours. If either time is exceeded re-heat

treatment is required. See Figure 3-1-D for head identification.

c. 2024-0 or 2024-T4 (DD) Rivets. The same conditions apply for these rivets as for the 2017 (D) except heat treat at 920°F

10°F. See Figure 3-1-DD for head identification.

d. 1100 and 5056 Rivets. These do not require heat treatment, install as received. See Figure 3-1-A and 3-1-B for

identification.

CAUTION

Rivets which have been anodically oxide coated should not be reheat-treated in direct contact with

molten salts more than 5 times.

e. D/DD Rivets. These may be stored in refrigerators which ensure that the rivet temperature does not rise above minus 100F.

Rivets held at minus 10°F or below can be retained for use indefinitely. When the rivets are transported, their temperature will be

maintained at minus 10°F or below by being carried in refrigerated boxes. MS20426E and MS20470E, do not require heat treatment,

install as received. See fig. 3-1-E for head identification.

(1) Quality control shall be responsible for periodically checking the temperature of each refrigerator and for prohibiting the use

of rivets in any box when the temperature becomes excessive.

(2) Each refrigerator shall have the rivets removed and be thoroughly cleaned at least once every six months. A tag or placard

that denotes the next cleaning date shall be attached to each refrigerator.

(3) Rivets which remain out of refrigeration for 30 minutes or more shall be reheat treated. These rivets can be reheat treated a

maximum of three times.

3-38. ANNEALING. Aluminum alloys are annealed to remove the effects of solution heat treatment and strain hardening. Annealing

is utilized to help facilitate cold working. Parts work hardened during fabrication are annealed at various stages of the forming

operation so that complicated shapes can be formed. During prolonged forming or stamping operations the metal becomes strain

hardened (commonly called "work hardened") and upon the performance of additional work it will split or crack.

When the above is encountered it is usually necessary to anneal the part one or more times at progressive stages of the forming

operation, if the part is to be successfully completed.

CAUTION

Annealed aluminum parts shall not be used for parts or fittings on aircraft or missiles unless specified

by drawings or other approved engineering data

Change 17 3-18