TM 55-4920-401-13&P

should indicate resistance specified for aircraft being

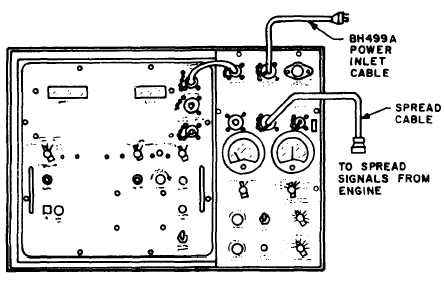

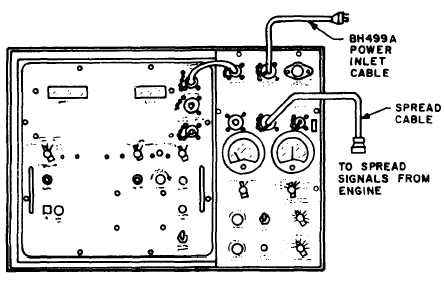

2-6. Temperature Spread Test. The temperature

checked.

spread test checks combustion chamber flame prop-

(10) If either insulation resistance reading is not

agation during engine run. During this test, the

within tolerance, locate source of leakage and repair.

temperature of each thermocouple in the engine can

be read independently with the tester. The average

NOTE

temperature may also be read at any time during

the test. Refer to figure 2-8 and proceed as follows:

Healing of EGT harness of 200 degrees F for

a. Turn FUNCTION SELECT, STD DAY, and

1 hour, letting cool to ambient temperature,

MASTER POWER switches to OFF position.

will increase insulation resistance.

b. Connect spread cable to SPREAD CABLE re-

ceptacles on tester and to spread connector on en-

( 1 1 ) T u r n F U N C T I O N S E L E C T a n d

gine (if required, use spread adapter).

MASTER POWER switches to OFF position before

c. Turn FUNCTION SELECT switch to SPREAD

removing cables from tester and aircraft.

position.

Figure 2-8. Temperature Spread Teat Setup.

d. Turn TEMPERATURE switch to OPERATE

position and MASTER POWER switch to ON posi-

tion.

e. Start engine and stablize rpm.

f. Turn SPREAD switch successively to each

thermocouple position and note reading of each

t h e r m o c o u p l e o n t e s t e r T E M P i n d i c a t o r .

Temperature gradient (spread) between engine

t h e r m o c o u p l e s s h o u l d n o t e x c e e d a l l o w a b l e

technical manual limits.

g. Turn FUNCTION SELECT and MASTER

POWER switches to OFF position before removing

cables from tester and aircraft.

2-5 Engine Trim Check. During operation, the

relationship between rpm, temperature, and fuel

flow is critical. Therefore, the tester, which

measures rpm to ± 0.1 percent and temperature to

± 2 degrees C, is used to measure these engine

functions. The portable trimmer portion may be

removed and placed in the cockpit during trimming.

If aircraft has D’Arsonval type indicator(s) and it is

desirable to check indicator accuracy during engine

trim, a switch box (fig. 2-9), which is an accessory to

the tester, must be used. Refer to figure 2-10 or 2-11

and proceed as follows:

a. Turn FUNCTION SELECT. STD DAY, and

MASTER POWER switches to OFF position and T/

C INPUT switch to CHECK CABLE position.

NOTE

If trimmer section is to be removed

and placed in cockpit, remove power

i n t e r c o n n e c t c a b l e f r o m t e s t e r .

Connect power cable and power cable

adapter to POWER INTERCONNECT

c o n n e c t o r a n d t o p o w e r s o u r c e

i d e n t i f i e d

a t t h e P O W E R

I N T E R C O N N E C T c o n n e c t o r .

Disregard reference to FUNCTION

S E L E C T a n d T / C I N P U T s w i t c h

positions.

Change

4

2-9