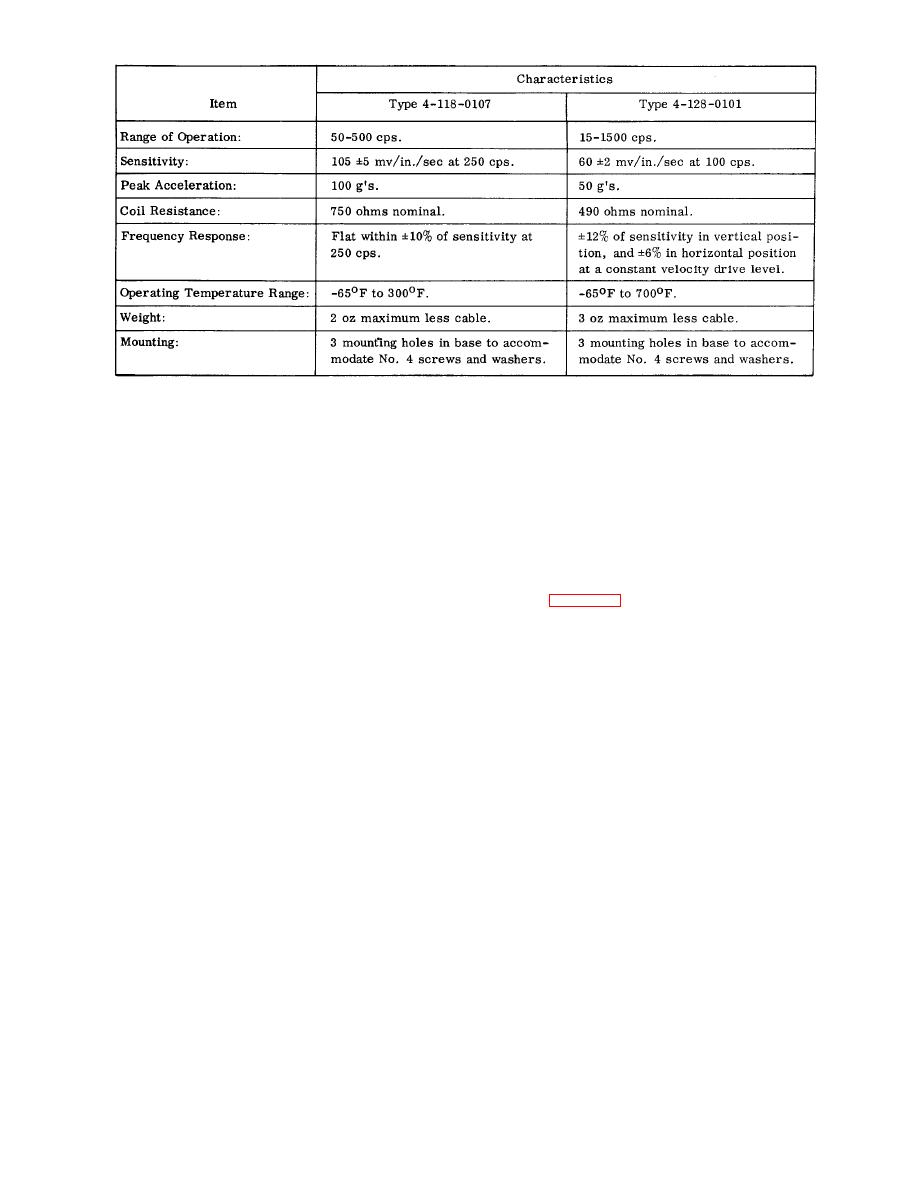

Technical Characteristics, Vibration Transducer Types 4-118-0107 and 4-128-0101

1-24. APPLICATIONS.

1 - 2 0 . RECORDING EQUIPMENT. The vibration

meter output may be permanently recorded for de-

tailed waveform study by connecting a galvanometers

1-25. The vibration test kit measures engine vibra-

tion at specified operating speeds of the N1 and N2

of a recording oscillograph to the GALV. connector

on the rear panel of the vibration meter. The vibra-

systems. Vibration transducers attached to adapters

tion meter readings are not affected by the use of this

mounted on the engine, transmit electrical impulses

connector. Full scale on the meter corresponds to

through cables to the vibration meter. The vibration

approximately 555 microampers rms in the galva-

meter indicates the total amount of engine movement

nometer circuit. Galvanometers with resistance of

(peak-to-peak displacement) in mils. Meter indica-

100 ohms or less should be used.

tions are recorded on an Engine Vibration Test Data

Sheet (see figures 1-9 through 1-12). The recorded

1-21. OSCILLOSCOPES. A cathode-ray oscilloscope

figures are compared with the figures given on the

with an input impedance of 0.5 megohm or greater

data sheet for maximum permissible engine vibra-

may be connected to the SCOPE connector on the front

tion. If these maximum figures are exceeded, the

panel of the vibration meter. This permits simul-

cause of the excessive vibration must be found and

taneous viewing of the amplitude and velocity indica-

corrected before the engine can be accepted for

tions on the vibration meter and waveforms on the

unrestricted flight.

1-26. Vibration engine tests are performed by third

echelon maintenance activities. Measurements are

1-22. EXTERNAL METER. An external meter may be

taken after removal and installation of the first stage

used for remote indication of velocity of displacement.

turbine rotor assembly, the engine combustion sec-

This meter should have a full scale value of 500 micro-

tion, the engine exhaust section, or when excessive

ampere dc and a resistance of 200 ohms or less.

engine vibration is suspected.

1-23. CONTROL AND WARNING DEVICES. A wide

1-27. PREPARATION FOR USE.

variety of special circuits may be devised for auto-

matic control of equipment, or for warning operators

1-28. Paragraphs 1-29 through 1-30 are installation

of unsafe vibrations of any predetermined magnitude.

procedures and preliminary checkout procedures for

Any of the three vibration meter output circuits may

the vibration test kit.

be used for this purpose, provided the impedances in-

troduced are within the specified ranges. Devices con-

1-29. PRELIMINARY SYSTEM CHECKOUT. Prior

nected to the ac outlets should have pure resistive

to installation of mounting adapters and transducers

inputs. All three output connections may be used

on the engine, check the system out to be sure that

simultaneously.

all parts are functional, as follows: