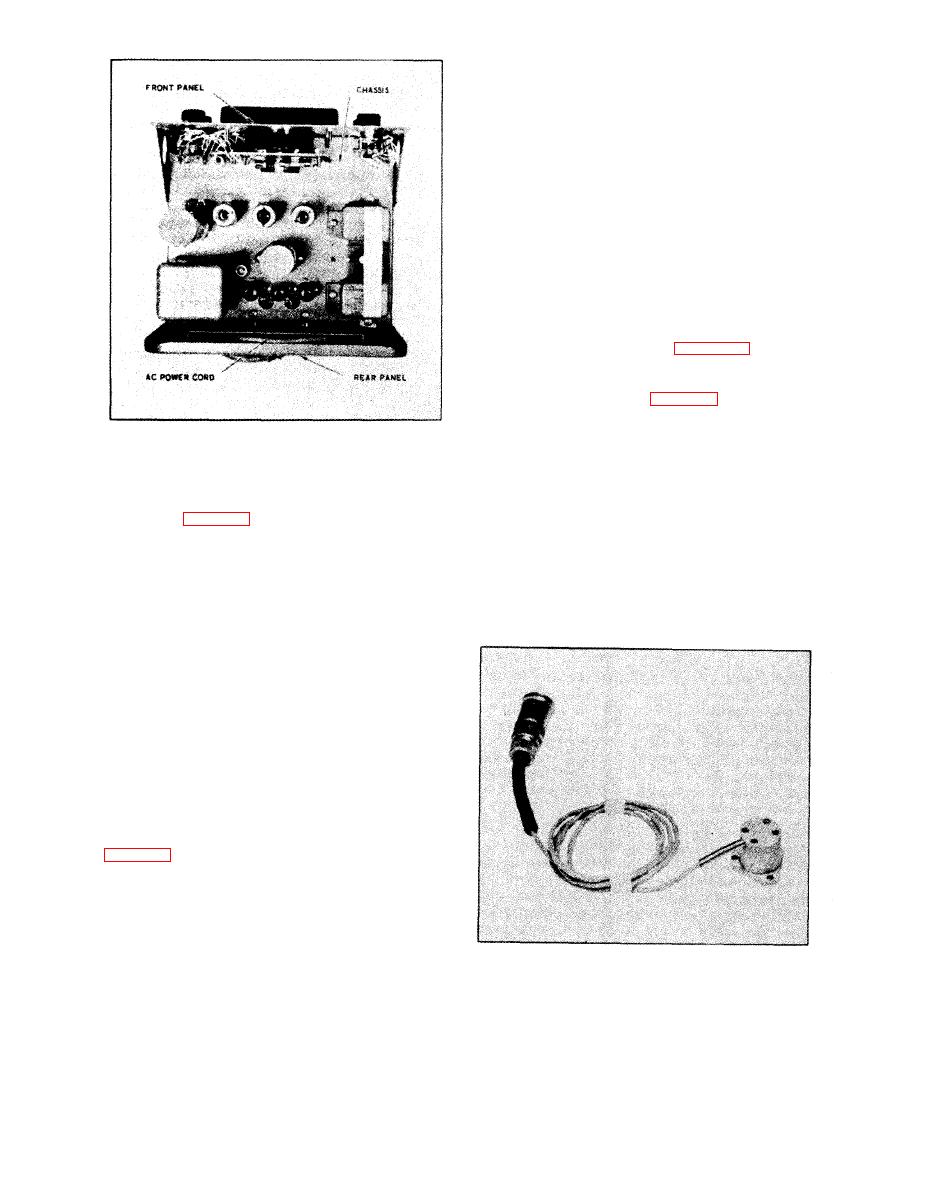

vided for each channel for adjusting the channel gain

for the type of transducer being used. A self-

generated calibration signal provides a means for

calibrating each channel individually. The output of

the selected channel is normally read directly on the

meter. The front panel contains an indicating meter

and the primary operating controls. Four sensitivity

controls are located behind an access door near the

bottom of the front panel. An electrical connector is

provided on the front panel for connecting an oscillo-

scope to the vibration meter output circuit. The rear

panel contains four channel input connectors, an

input power fuse, and connectors for connecting an

external remote meter and a galvanometers to the

vibration meter output circuit. A six-foot long ac

power cord is permanently attached to the vibration

meter. This cord is stored in a recessed section of

the rear panel as shown in figures 1-3 and 1-4.

1-7. VELOCITY VIBRATION TRANSDUCER ASSEM-

BLY, Type 4-128-0101. (See figure 1-5.) The velocity

vibration transducer is a linear, self-generating unit

that produces a voltage output proportional to vibra-

tional velocity. Measurements of vibratory motion is

Top View, Cover Removed

accomplished by using the seismic mass principle.

The transducer measures vibrations of from 15 to

per second). Additional equipment may be included in

1500 cps, and is designed for use with the Type

the system for further examination or for recording,

1-117-0105 Vibration Meter. The transducer con-

as shown in figure 1-2.

verts mechanical vibrations into ac voltage signals

1-4. PHYSICAL DESCRIPTION.

which are proportional to the velocity of vibration.

1-5. The vibration test kit consists of one vibration

1-8. CABLE ASSEMBLIES AND CABLE REELS. The

meter, three vibration transducers, five cable assem-

vibration monitoring kit includes three 300-inch cables

blies mounted on five cable reels, eight different

(Part No. 49657-300) and two 900-inch cables (Part

types of adapters and brackets for mounting the

No. 49657-900) wound on five cable reels (Part Nos.

transducers on the aircraft engine, and an ac ground-

ing plug adapter. All components are contained in a

hermetically sealed, aluminum carrying case for

maximum protection from outside environment. Each

component fits into an individual cutout of a molded

animal hair cushion support where they are further

protected against vibration and shock. The carrying

case has two handles on each end, and is secured

closed by six latches. A relief valve is included to

equalize the pressure inside the case. The carrying

case conforms to Specifications MIL-C-4150E, MIL-

T-945A, and MIL-STD-108D Class I.

1-6. VIBRATION METER TYPE 1-117-0105. (See

able precision instrument consisting of a chassis

assembly and case assembly. The chassis assembly

consists of a chassis suspended between a front panel

and a rear panel. The instrument provides four input

channels. Each channel will accommodate any self-

generating transducer with characteristics compatible

with the vibration meter. A sensitivity control is pro-