TM 55-1510-219-10

by two 10-ampere circuit breakers placarded STANDBY

PUMP #1 or #2, located on the overhead circuit breaker

panel (fig. 2-26), and four 5ampere circuit breakers (2

each in parallel) on the hot battery bus.

c.

Fuel Transfer Pumps. The auxiliary tank fuel

transfer system automatically transfers the fuel from the

auxiliary tank to the nacelle tank without pilot action.

Motive flow to a jet pump mounted in the auxiliary tank

sump is obtained from the engine fuel plumbing system

downstream from the engine driven boost pump and

routed through the transfer control motive flow valve.

The motive flow valve is energized to the open position

by the control system to transfer auxiliary fuel to the

nacelle tank to be consumed by the engine during the

initial portion of the flight. When an engine is started,

pressure at the engine driven boost pump closes a

pressure switch which, after a 30 to 50 second time delay

to avoid depletion of fuel pressure during starting,

energizes the motive flow valve. When auxiliary fuel is

depleted, a low level float switch de-energizes the motive

flow valve after a 30 to 60 second time delay provided to

prevent cycling of the motive flow valve due to sloshing

fuel. In the event of a failure of the motive flow valve or

the associated control circuitry, the loss of motive flow

pressure when there is still fuel remaining in the auxiliary

fuel tank is sensed by a pressure switch and float switch,

respectively, which illuminates a light placarded #1 or #2

NO FUEL XFR on the annunciator panel. During engine

start, the pilot should note that the NO FUEL XFR lights

extinguish 30 to 50 seconds after engine start. The NO

FUEL XFR lights will not illuminate if auxiliary tanks are

empty. A manual override is incorporated as a backup for

the automatic transfer system. This is initiated by placing

the AUX TRANSFER switch, located on the fuel

management panel (fig. 2-13) to the OVERRIDE position.

This will energize the transfer control motive flow valve.

The transfer systems are protected by 5-ampere circuit

breakers placarded AUXILIARY TRANSIEK #1 or #2,

located on the overhead circuit breaker panel (fig. 2-26).

NOTE

In turbulence or during maneuvers,

the NO FUEL XFR lights may

momentarily illuminate after the

auxiliary

fuel

has

completed

transfer.

d.

Fuel Gaging System. The total fuel quantity in

the left or right main system or left or right auxiliary tank

is measured by a capacitance type fuel gaging system.

Two fuel gages, one for the left and one for the right fuel

system, read fuel quantity in pounds. Refer to Section XII

for fuel capacities and weights. A maximum of 3% error

may be encountered in each system. However, the

system is compensated for fuel density changes due to

temperature excursions. In addition to the fuel gages,

yellow No. 1 or No. 2 NAC LOW lights on the caution/

advisory annunciator panel illuminate when there is

approximately 20 minutes of fuel per engine remaining

(on standard day, at Sea Level, Maximum Cruise Power

consumption rate). The fuel gaging system is protected

by individual 5 ampere circuit breakers placarded QTY

IND and QTY WARN #1 or #2, located on the overhead

circuit breaker panel (fig. 226). A mechanical spiral float

gage (fig. 2-13) is installed in the auxiliary fuel tank to

provide an indication of fuel level when servicing the tank.

The gage is installed on the auxiliary fuel tank cover,

adjacent to the filler neck. A small sight window in the

upper wing skin permits observation of the gage.

e.

Fuel Management Panel. The fuel management

panel (fig. 2-13) is located on the cockpit overhead

between the pilot and copilot. It contains the fuel gages,

standby fuel pump switches, the crossfeed valve switch

and a fuel gaging system control switch and transfer

control

switches

are

also

installed.

2-29

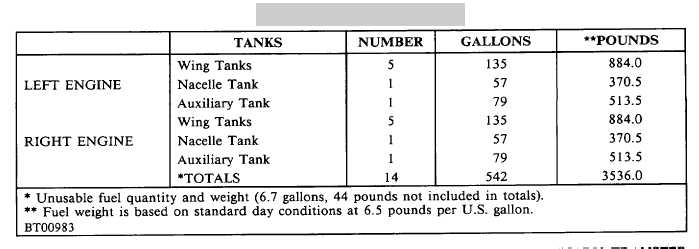

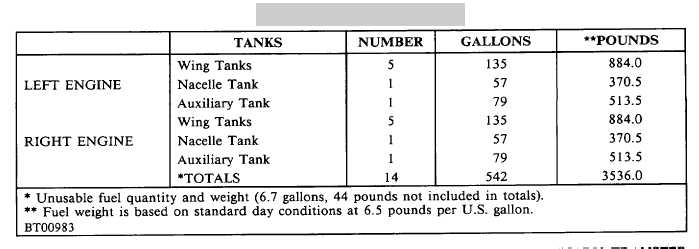

Table 2-2. Fuel Quantity Data