TM 55-1510-219-10

pump on the side from which crossfeed is desired. During

crossfeed operation with firewall fuel valve closed,

auxiliary tank fuel will not crossfeed. When the crossfeed

mode is energized, a green FUEL CROSSFEED light on

the caution/advisory panel will illuminate. Crossfeed

system operation is described in Chapter 9. The

crossfeed valve is protected by a 5-ampere circuit breaker

placarded CROSSFEED VALVE located on the overhead

circuit breaker panel (fig. 2-26).

f.

Firewall Shutoff Valves.

CAUTION

Do not use the fuel firewall shutoff

valve to shut down an engine,

except in an emergency. The

engine-driven highpressure fuel

pump obtains essential lubrication

from fuel flow. When an engine is

operating,

this

pump

may

be

severely damaged (while cavitating)

if the firewall valve is closed before

the condition lever is moved to the

FUEL CUTOFF position.

The fuel system incorporates a fuel line shutoff

valve mounted on each engine firewall. The firewall

shutoff

valves

close

automatically

when

the

fire

extinguisher T-handles on the instrument panel are pulled

out. The firewall shutoff valves receive electrical power

from the main buses and also from the hot battery bus

which is connected directly to the battery. The valves are

protected by circuit breakers placarded FIREWALL

VALVE #1 or #2 on the overhead circuit breaker panel

(fig. 2-26), and FIREWALL SHUTOFF #1 or #2 on the

hot battery bus circuit breaker board.

g.

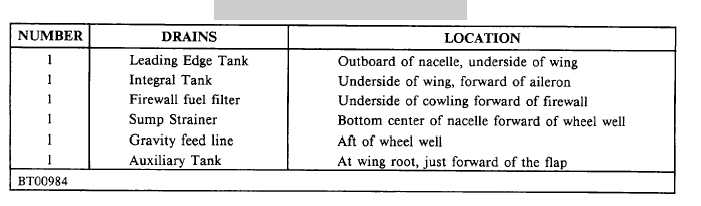

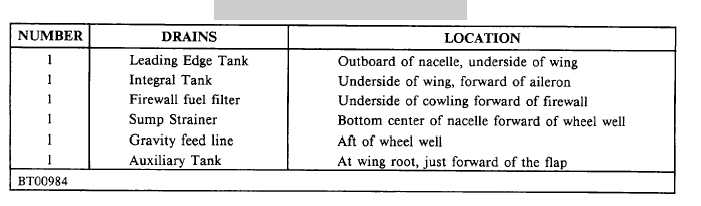

Fuel Sump Drains. A sump drain wrench is

provided in the aircraft loose tools to simplify draining a

small amount of fuel from the sump drain. There are five

sump drains and one filter drain in each wing (Table 2-3).

An additional drain for the extended range fuel system

line extends through the bottom of the wing center section

adjacent to the fuselage. Anytime the extended range

system is in use, a part of the preflight inspection would

consist of draining a small amount of fuel from this drain

to check for fuel contamination. Whenever the extended

range system is removed from the aircraft and the fuel

line is capped off in the fuselage, the remaining fuel in the

line shall be drained.

h.

Fuel Drain Collector System. Each engine is

provided with a fuel drain collector system to return fuel

dumped from the engine during clearing and shutdown

operations back into its respective nacelle tank. The

system draws power from the #4 feeder bus. Fuel

transfer is completely automatic. Fuel from the engine

flow divider drains into a collector tank mounted below the

aft engine accessory section. An internal float switch

actuates an electric scavenger pump which delivers the

fuel to the fuel purge line just aft of the fuel purge shutoff

valve. A check valve in the line prevents the backflow of

fuel during engine purging. The circuit breaker for both

pumps is located in the fuel section of the overhead

circuit breaker panel; placarded SCAVENGER PUMP. A

vent line, plumbed from the top of the collector tank, is

routed through an inline flame arrestor and then

downward to a drain manifold on the underside of the

nacelle.

i.

Fuel Vent System. Each fuel system is vented

through two ram vents located on the underside of the

wing adjacent to the nacelle. To prevent icing of the vent

system, one vent is recessed into the wing and the

backup vent protrudes out from the wing and contains a

heating element. The vent line at the nacelle contains an

inline flame arrestor.

j.

Engine Oil-to-Fuel Heat Exchanger. An engine

oil-to-fuel heat exchanger, located on each engine

accessory case, operates continuously and automatically

to heat the fuel delivered to the engine sufficiently to

prevent the freezing of any water which it might contain.

The temperature of the delivered fuel is thermostatically

regulated

to

remain

between

21°C

and

32°C.

2-34

Table 2-3. Fuel Sump Drain Locations