TM 55-1510-219-10

opened, allows the distribution of the pressurized

extinguishing agent through a plumbing network of spray

nozzles strategically located in the fire zones of the

engines.

b.

Fire Pull Handles. The fire control handles,

which are used to arm the extinguisher system are

centrally located on the pilot's instrument panel (fig. 2-

28), immediately below the glareshield. These controls

receive power from the hot battery bus. The fire detection

system will indicate an engine fire by illuminating the

master fault warning light on the pilot's and copilot's

glareshield and the respective #1 or #2 FIRE PULL lights

in the fire control T-handles. Pulling the fire control T-

handle will electrically arm the extinguisher system and

close the fuel firewall shutoff valve for that particular

engine. This will cause the red light in the PUSH TO

EXTINGUISH switch and the respective red #1 and #2

FUEL PRESS light in the warning annunciator panel to

illuminate. Pressing the lens of the PUSH TO

EXTINGUISH switch (after lifting one side of its spring-

loaded clear plastic guard) will fire the squib, expelling all

the agent in the cylinder at one time. The respective

yellow caution light, #1 or #2 EXTGH DISCH on the

caution/advisory annunciator panel will illuminate and

remain illuminated until the squib is replaced.

c.

Fire Extinguisher System Test Switch. A rotary

test switch, placarded FIRE PROTECTION TEST, is

located on the copilot's subpanel. The test functions,

placarded EXTGH #1 #2, are arranged on the left side of

the switch and provide a test of the pyrotechnic cartridge

circuitry. During Before Exterior Check, the pilot should

rotate the test switch through the two positions and verify

the illumination of the green SQUIB OK light on the

PUSH TO EXTINGUISH switch and the corresponding

yellow

#1

or

#2

EXTGH

DISCH

light

on

the

caution/advisory annunciator panel.

d.

Fire

Extinguishing

System

Supply

Cylinder

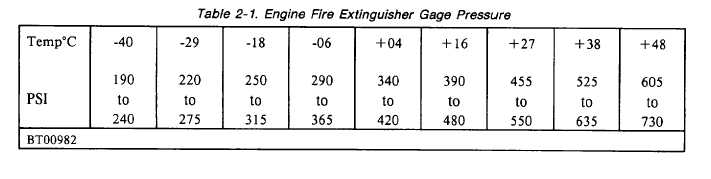

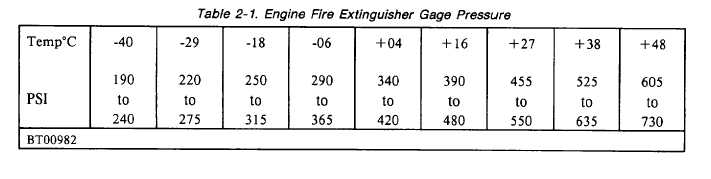

Gages. A gage, calibrated in PSI, is mounted on each

supply cylinder for determining the level of charge and

should be checked during preflight (table 2-1).

2-27. OIL SUPPLY SYSTEM.

a.

The engine oil tank is integral with the air-inlet

casting located forward of the accessory gearbox. Oil for

propeller operation, lubrication of the reduction gearbox

and engine bearings is supplied by an external line from

the high pressure pump. Two scavenge lines return oil to

the tank from the propeller reduction gearbox. A non-

congealing external oil cooler keeps the engine oil

temperature within the operating limits. The capacity of

each engine oil tank is 2. 3 U. S. gallons. The total

system capacity for each engine, which includes the oil

tank, oil cooler, lines, etc. , is 3. 5 U. S. gallons. The

oil level is indicated by a dipstick attached to the oil filler

cap. Oil grade, specification and servicing points, are

described in Section XII, Servicing.

b.

The oil system of each engine is coupled to a

heat exchanger unit (radiator) of fin-and-tube design.

These exchanger units are the only airframe mounted part

of the oil system and are attached to the nacelles below

the engine air intake. Each heat exchanger incorporates

a thermal bypass which assists in maintaining oil at the

proper temperature range for engine operation.

2-28. TORQUE LIMITER

A torque limiter is installed in the torquemeter

pressure transmitter boss on the front case of the

propeller reduction gearbox. The limiter incorporates a

sealed bellows, connected directly to torquemeter oil

pressure, which works against an externally adjustable

torque-limit spring. Torquemeter oil pressure is sensed at

the inside of the bellows assembly, and during normal

operating conditions the torquemeter oil pressure is not

high enough to compress the torque-limit spring. When

high torque pressure is sensed, the bellows will stretch

and compress the spring assembly. This will permit a

limited amount of governing air pressure to be bled from

the fuel control unit and will continue to do so until engine

speed is reduced, resulting in a proportional reduction in

engine torque pressure.

2-26