CHAPTER 5

DIRECT SUPPORT AND GENERAL SUPPORT

MAINTENANCE INSTRUCTION'S

Section I. REPAIR PARTS, SPECIAL TOOLS AND EQUIPMENT

maintenance of the insecticide sprayer.

5-1. Tools and Equipment

Tools, equipment, and spare parts issued with or

5-3. Maintenance Repair Parts

authorized for the aircraft-mounted insecticide

sprayer are listed in the basic issue items list,

Repair parts and equipment covering Direct Sup-

port and General Support maintenance levels for

the insecticide sprayer are listed and illustrated

5-2. Special Tools and Equipment

in TM 5-3740-211-24P.

No special tools or equipment are required for

Section II. TROUBLESHOOTING

insecticide sprayer.

The chart serves only as a guide

5-4. Toubleshooting Chart

and does not preclude the chance that other troubles

exist.

and General Support maintenance level for the

Section III. GENERAL MAINTENANCE

removal of hoses, use procedures given in paragraph 4-

5-5. Removal of Components

15, step c.

When installation calls for attachment of

Removal of major components, as described in section

hoses, use procedures given in paragraph 4-15, steps d

IV following, often requires removal of components

and e.

Clean all threaded connectors thoroughly.

authorized for removal by organizational maintenance

Use MIL-T-27730 teflon tape on all pipe threads.

level.

When procedures are lacking for removal of

Use suitable thread lubricant on all tube fittings.

parts, refer to pertinent paragraphs of chapter 4.

Use tire soap on inside diameter of low-pressure

5-6. Hose Removal and Installation

hoses to aid in installation.

Whenever removal of major components calls for

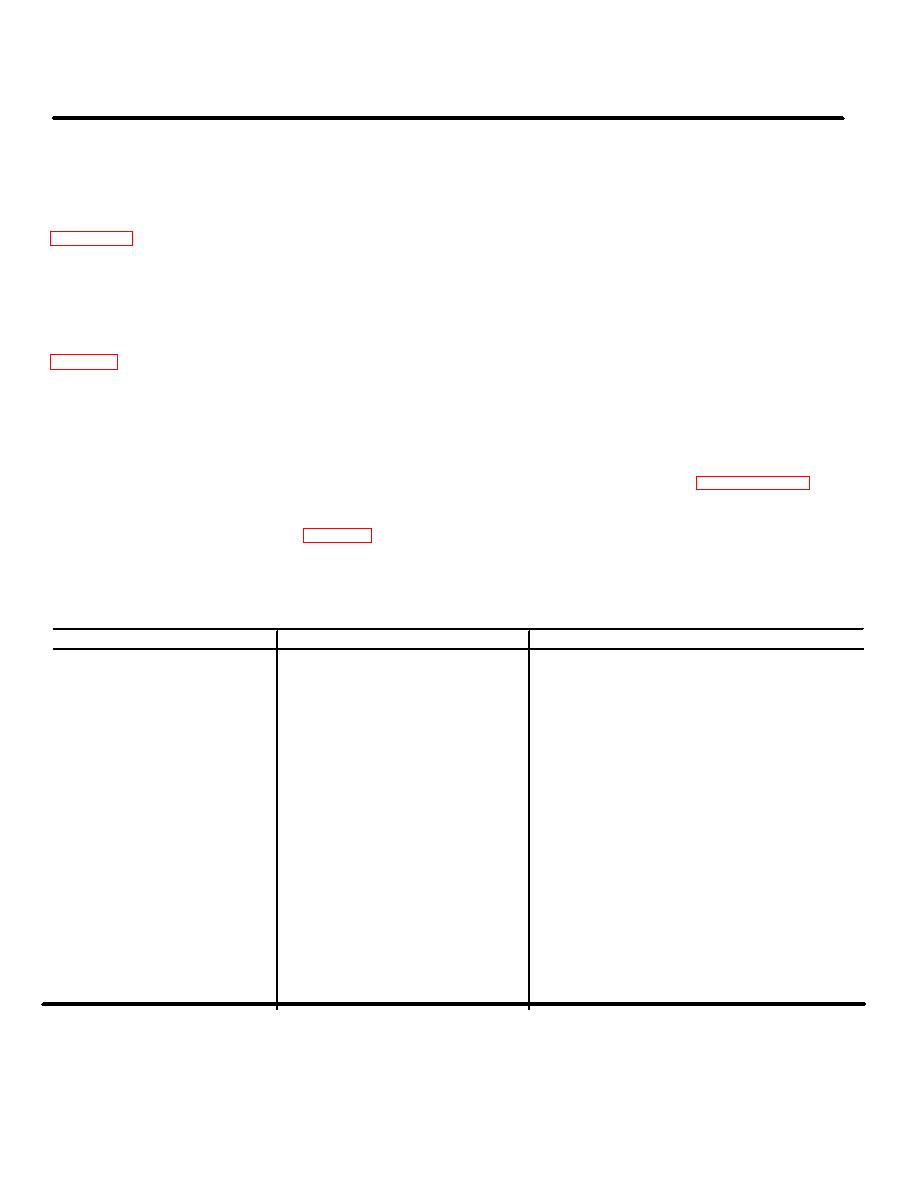

Table 5-1. Direct Support and General Support Troubleshooting Chart.

Malfunction

Probable cause

Corrective action

1.

Tank support damaged.

Combat damage or improper handling.

Repair or replace damaged components

(9-1/9-4).

2.

Leaks in tank.

a. Holes or cracks.

a. Repair tank (8-12).

b. Severe damage or faulty seals.

b. Replace tank (8-9/8-14).

3.

Couplings leak.

a. Foreign particles present.

a. Clean couplings.

b. Faulty seals

b. Replace coupling (8-6/8-8).

4.

Leak develops in system installed in

Faulty fluid system components.

Repair or replace faulty components.

aircraft.

5.

Use of pump causes vibration.

Pump bearings faulty.

Replace pump bearings (7-11/7-16).

6.

Pump leaks through weep holes.

Seals faulty

Replace seals (7-11/7-16).

7.

No response to spray command.

a. Faulty control valve.

a. Replace or repair control valve (8-1/8-5).

b.

Pump brake sticks.

b.

Replace brake cable (4-22) or repair pump brake (7-

7/7-10).

8.

No response to stop spray command. a.

Faulty control valve.

a.

Remove and repair control valve (8-1/8-5).

b.

Pump brake sticks.

b.

Replace brake cable (4-22) or remove and repair

pump brake (7-7/7-10).

9.

Spray intermittent.

Faulty synchromatic windmill pump drive.

Remove and repair pump and brake assembly and

windmill assembly as required (7-2/7-16).

10. Spray uneven.

Faulty pump.

Remove and repair pump (7-11/7-16).

11. Unable to adjust windmill blade angle. Synchromatic windmill internal mechanism -

Remove and repair synchromatic windmill

damaged.

assembly (7-2/7-6).

5-1