PREPARING THE PUMP

UNPACKING

Please read this manual through carefully, at least once,

before you attempt to start and operate the pump. If

you discover that anything was damaged in shipment, or

is missing from the carton, NOTIFY THE SHIPPER

IMMEDIATELY.

Lift the pump out of the carton and strip all of the

packing pieces from the pump. In addition to the pump,

and the manual, you should also find included; a

combination wrench that is very useful.

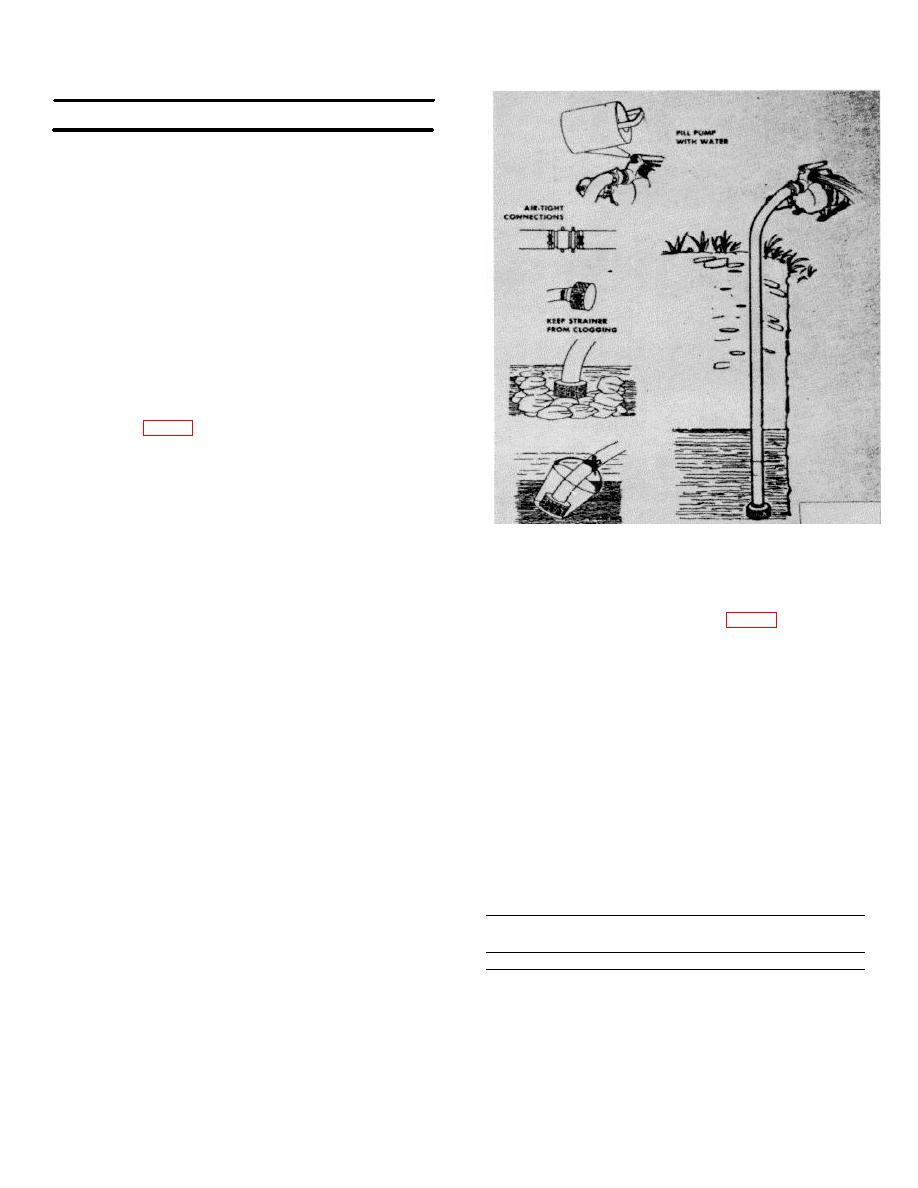

FILL PUMP BODY WITH LIQUID USED

Pour through the intake or discharge nipple, or remove

filler cap, 3, fig 15, and fill through that opening. If

removed, filler cap and gasket must be put back tightly

before pump can be used. Although the pump cannot

prime in dry condition, once filled with water, it will retain

water for automatic priming, and need not be refilled

except if overturned or drained. Draining can be

accomplished either by removing the drain cap and

FIGURE 16. PROPER USE OF SRAINER

gasket (17). or by disconnecting hoses and turning the

pump over. The pump should be drained for shipping

and storing purposes, and in cold weather locations,

When soft, muddy bottom presents a problem of

whenever it is to be shut down long enough to freeze.

clogging, the strainer can often be kept from burying

Before cranking the engine in cold weather, always pull

itself by tying it inside a pail. See fig 16. For seepage

the starter just enough to see whether crankshaft will

control, dig a hole in the floor of the excavation and line

turn freely. If the impeller Is frozen fast, heat the pump

the side of the hole with large rocks-set strainer inside

gradually until the ice melts.

the lined hole. If strainer becomes clogged, pull hose

from water and clean the strainer.

MAKE AIR-TIGHT, FLEXIBLE CONNECTIONS

MIX FUEL IN EXACT PROPORTIONS

All connections on the suction side of the pump must be

made air-tight, or the unit will not prime. Connections

Mix thoroughly in a clean container, pint of a good

on both suction and discharge sides must be flexible,

grade of SAE-30 motor oil per gallon of fresh, regular

permitting floating action of the pump on its mounting.

gasoline. DO NOT FILL THE TANK WHEN THE

When rigid pipe is used, always connect a short section

ENGINE IS RUNNING AS THIS MAY CAUSE A FIRE.

of flexible hose between pipe and pump to maintain

After filling the tank be sure to wipe up any spilled fuel

flexibility. Lay hose out carefully; there should be no

before you start the engine.

sharp bends or kinks in the hose. If hose must be laid

FUEL MIXING TABLE

across a roadway, protect it with planking.

1:16 ratio of S.A.E. 30 Motor Oil to regular gasoline

Instantaneous shut-off pressures, applied when a

vehicle runs across unprotected hose, cause pounding -

OIL

1/2 pint

1 pint

1 quart

can split pump body or damage the hose.

(8 oz.)

(16 oz.)

(32 oz.)

GASOLINE

1 gal.

2 gal.

4 gal.

USE PROPER STRAINER ON SUCTION HOSE

Because this two-cycle engine depends on the oil in the fuel

The strainer prevents particles which could clog the

mixture for internal lubrication, it is important that the fuel be

pump from being sucked into it. Attach the strainer to

uniform in oil content. Moreover, the gasoline should be both

the suction hose and never pump without it.

clean and fresh. All mixing equipment and containers should

be clean. Because oil and gasoline do not combine readily,

Locate the strainer over rock, or as firm a bottom as

the mixing should be done before the fuel is poured into the

possible.

fuel tank.

44