T.O. 1-1A-9

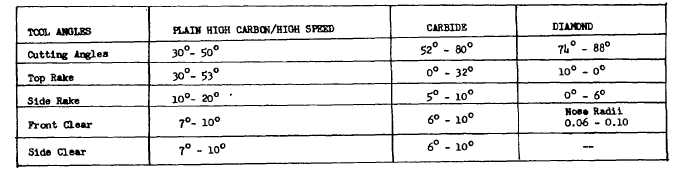

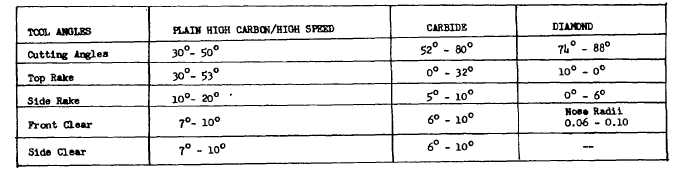

TABLE 3-23. TOOL ANGLES - TURNING.

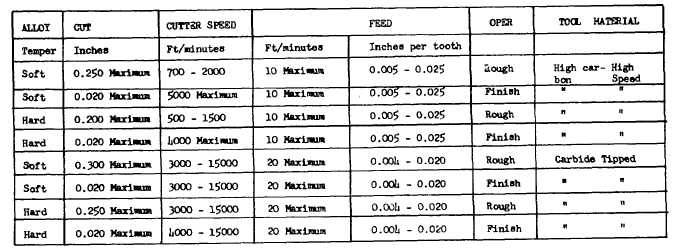

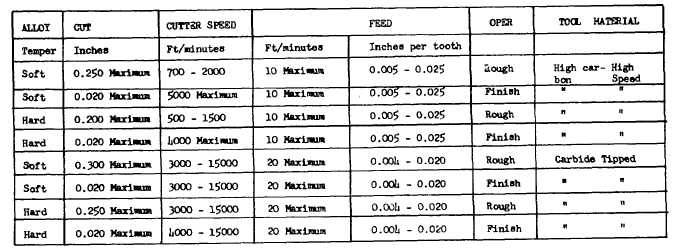

TABLE 3-24. MILLING - SPEEDS AND FEEDS.

Lip Clearance (lip relief): 17 for soft alloys 15 for medium and hard alloys, 12° for silicon alloys Speed: 600 ft/min with

high speed drills and up to 2000 ft/min with carbide tipped drills,

Feed: 0.004-0.012 inch per revolution for drills 3/8 inch diameter, 0.006-0.020 in/rev for 3/8 1 ¼ inch diameter and 0.016

to 0.035 in/rev for drills over 1 ¼ inch diameter. When using carbide tipped drill, feed should be slightly less. Feed also

may be determined by the formular feeds square root of drill diameter (inches) divided by 60 feet: Drill diameter (IN) +

0.002.

b.

Lathe/screw-machine.

Point Angle: 118° 1400

Spiral Angle: 0-28

Lip Clearance (lip relief): 15° 20°

Speed ft/min up to 1500

Feed inches/revolution 0.004-0.016.

(c)

Portable Drills Electric/Air Driven. Due to variables involved no set factors can be given. However, factors

given for drill press should be used as a guide. Feed should be adjusted in accordance with speed of motor to prevent

tip heating and also to satisfy operation/operator.

WARNING

When operating any machinery all safety precautions must be observed, i.e., safety goggles

shall be worn when grinding/ drilling. Machinery shall be inspected to insure that safety

guards are in place/ for safe operation etc. prior to operating. Work shall be securely

clamped to prevent slippage. Consult safety officer when in doubt about the safety of an

operation.

3-194. The drilling of thin material normally does not require coolant/lubrication however adequate lubrication is

essential to drill life and hole quality when drilling holes of ¼ inch depth or more. Soluble oil emulsions and lard oil

mixtures are satisfactory for general drilling. The lubrication should be applied by forced feed spray/flow where possible

and the drill should be withdrawn at intervals to be sure lubricant flows to the drill tip (fill holes completely) when drill is

withdrawn.

3-48