T.O. 1-1A-9

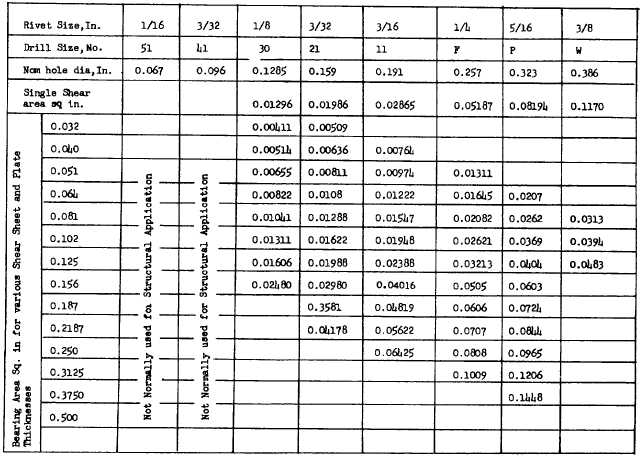

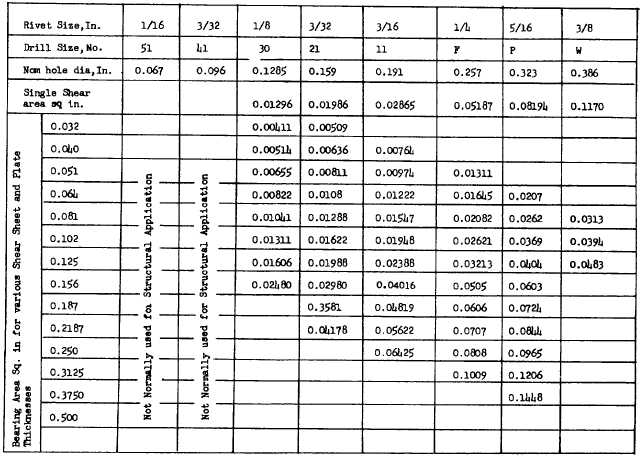

TABLE 3-21. STANDARD RIVET HOLE SIZES WITH CORRESPONDING SHEAR

AND BEARING AREAS FOR COLD DRIVEN ALUMINUM ALLOY RIVETS.

The slower cutting speeds can be overcome to some

extent by securely anchoring the work to the machine

and using heavy rough cutting feeds. The tools used for

rough cut should be (round nose) of heavy construction

and properly ground to operate efficiently. Rough cut

tools should be ground with moderate amount of rake to

provide maximum cutting edge support. Finish tool

should have more top rake and an extra large amount of

side rake. Finishing tool shall be used with fine feeds

only due to the additional side and top rake (finish cut

should not exceed 0.018 inch).

3-190. Most cutting operations by shaping and planing

can be accomplished without cutting fluids, however fine

finishing

can

be

improved

by

lubrication..

Recommended

cutting

compounds

are

kerosene,

mixture of 50-50 lard-oil and soluble oil.

3-191. Tables 3-26 and 3-27 cite suggested turning

speeds, tool angles and feeds. Secure clamping of work

is re-emphasized especially when heavy cutting feeds

are to be used.

3-192. DRILLING ALUMINUM ALLOY . Standard type

twist drills may be used satisfactorily for many drilling

operations in aluminum alloys. However, better results

can be obtained with improved designed drills where

soft material and drilling of thick material or deep holes

are involved. These drills are usually designed having

more spiral twists per inch (see Figure 3-2). The

additional spiral twist gives more worm action or force to

drill causing the drill to cut/feed faster and is helpful in

removing chips, especially in deep hole drilling

operations.

3-193. Generally a drill for a given job should be

selected according to the thickness, type alloy and

machine/drill motor to be utilized. The following is a

general

guide

for

the

selection

of

drills

and

recommended speeds:

(a)

Drill press.

Point Angle: 118-140 for general work and 90°-120°

for high silicon.

Spiral Angle: 24-28 for thin stock and medium depth

holes up to 6 times drill diameters, 24°-48° for deep

holes over 6 times drill diameter.

3-46