T.O. 1-1A-9

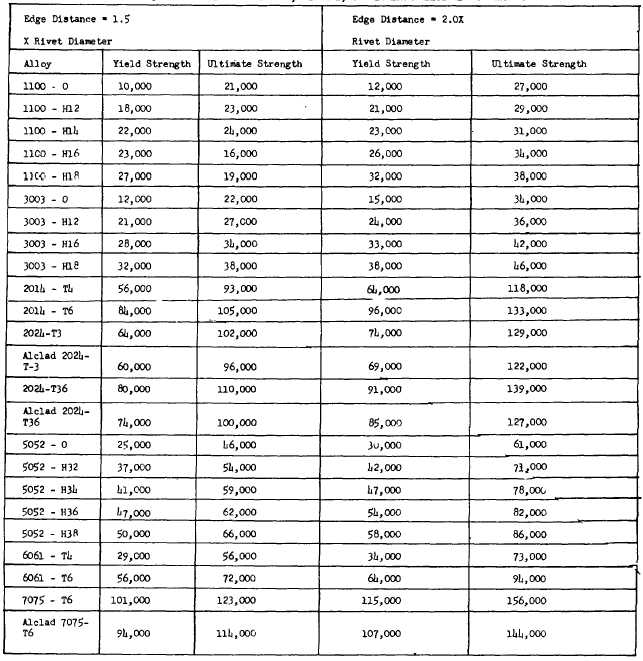

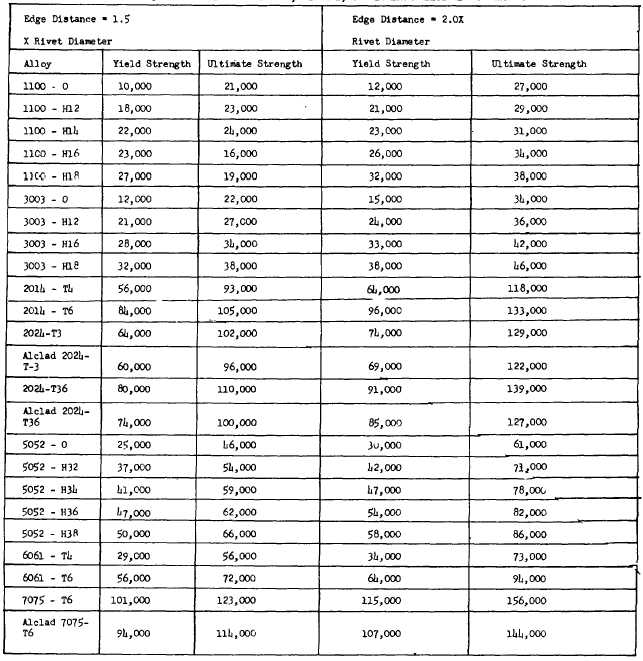

TABLE 3-20. BEARING PROPERTIES, TYPICAL, OF ALUMINUI ALLOY PLATES AND SHAPES.

3-186. Milling cutters should be inclined to work

3-188. Tables 3-24 and 3-25 cite suggested speeds,

and beveled on leading corner (least bevel for finish

contour and tool angles, for milling aluminum. The

cuts) to minimize clatter.

best combination of cutting speeds, feed and cut for

a given job will depend on design of tool/cutter, kind

3-187. The cutting fluids for milling aluminum

of tool material, condition of machine, machine power,

should combine cooling and lubrication properties.

size, clamping method and type material being worked.

Coolant lubrication should be applied under pressure

(atomized spray if available) in large quantities to

3-189. SHAPING AND PLANING . The speed at which

tool and work. The recommended cutting fluids are

aluminum alloys can be cut by planing and shaping is

water base cutting fluids such as soluble oils and

somewhat slower in comparison to other machining

emulsions, mixed 1 part to 15 for high speeds and

methods, due to equipment design and limitations.

1 part to 30 for low speed cutting.

3-45