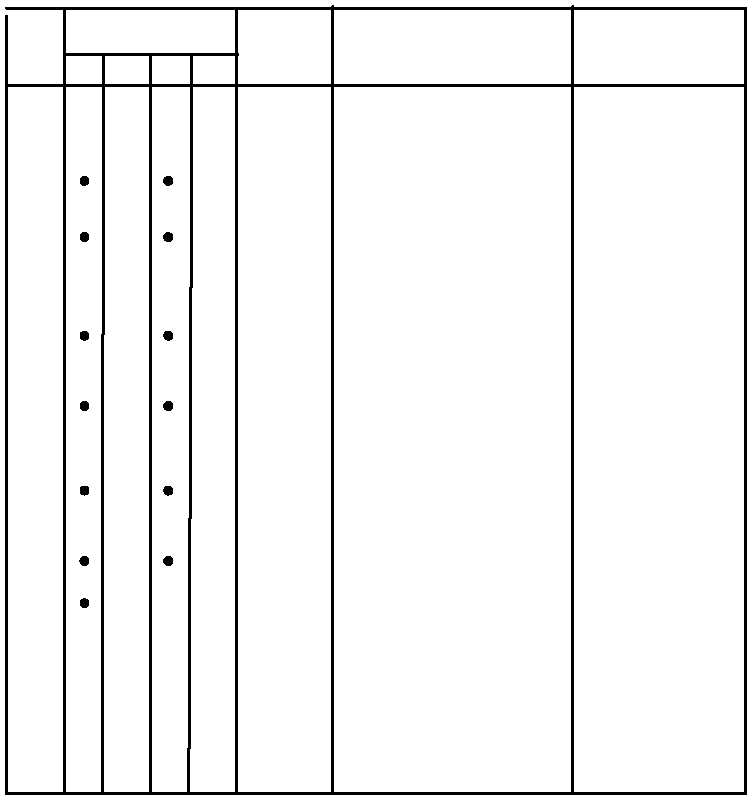

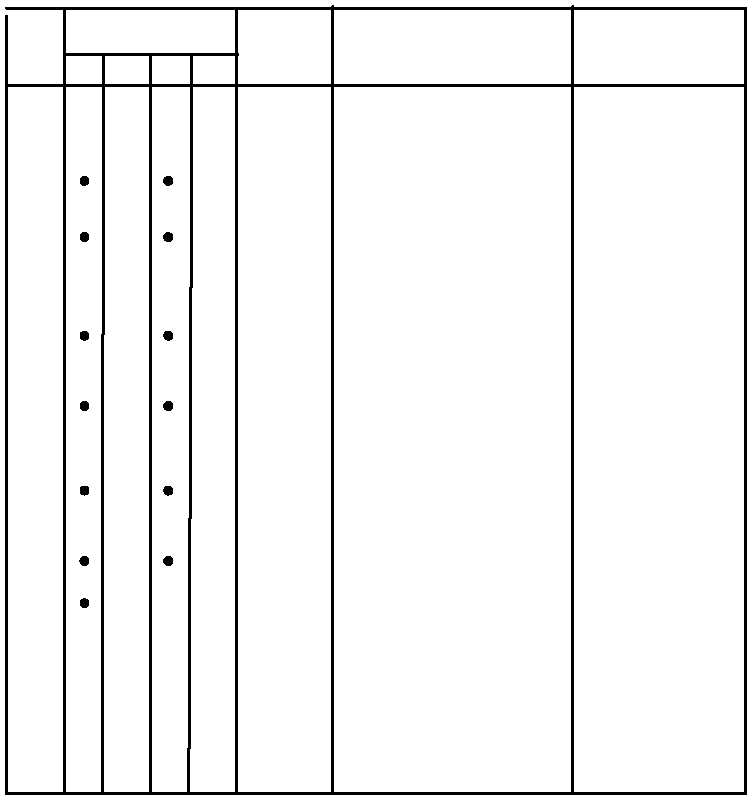

TM 1-8415-215-12&P

Table 2-1. Operator's Preventive Maintenance Checks and Services (Continued)

B

D

A

W

Outer Edge

8.

Beading

Inspect for cracks, looseness or

Cracked, deterior-

other defects. If defective beading,

ated, loose or

refer to Chapter 3, Maintenance.

missing beading.

9.

Microphone

Inspect for loose connection

Screws are

and Headset

screws on rear attachment

missing, micro-

point on helmet; loose

phone will not

microphone or boom.

stay in position

or rear retainer clip

plate is missing.

10.

Night Vision

Inspect for loose screws.

Screws are loose.

Goggle

Attachment

Device

11.

Hook & Pile

Inspect hook & pile to make sure

Hook & pile is

it is not coming loose.

coming loose.

Thermo Plastic

Liner

12.

TPL Cover

Inspect stitching to make sure

Broken or missing

they are not broken. Inspect

stitching.

for holes or worn spots.

Holes or worn spots

in cover.

13.

Plastic Layer

Inspect for minimum of two layers.

Less than two

Assembly

layers.

14.

TPL

Insure proper fit of assembly

Proper fit cannot

Assembly

on users head.

be made by minor

adjustments.

Item To Be

Inspected

Equipment will be

reported not ready/

Available if:

INTERVAL

ITEM

NO.

PROCEDURES

Check for and have repaired

or adjusted as necessary:

2-12