TM 55-1510-221-10

STABILIZED CYLINDER TEMPERATURE

500

1,000

1,500

2,000

CYLINDER PRESSURE (PSIG)

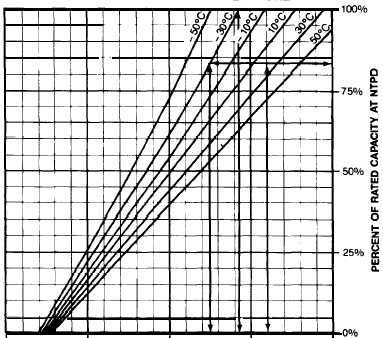

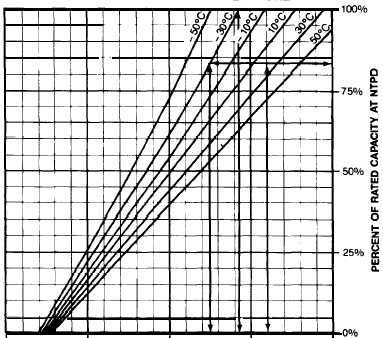

Figure 2-20. Cylinder Capacity vs Pressure and Temperature

KNOWN

Pressure = 1,600 PSIG stabilized cylinder tem-

perature is estimated at 20º C decreased stabilized

cylinder temperature is estimated at -30º C.

METHOD

a. Enter 1600 PSIG move up to 20º C line,

move right to 84%.

b.

Move left on 84% line to -30º C line, move

down to 1250 PSIG.

WANTED

100% capacity pressure at known temperature.

KNOWN

Temperature = -30º C.

METHOD

Move left along 100% line to -30º C line and

move down to 1420 PSIG.

(1.)

Regulator control panels. Each regula-

tor control panel contains a blinker-type flow indica-

tor, a 500 PSI pressure gage, a red emergency pres-

sure control lever placarded EMERGENCY -

NORMAL - TEST MASK, a white diluter control

lever placarded 100% OXYGEN - NORMAL OXY-

AP010340

GEN, and a green supply control lever placarded

ON - OFF. The diluter control lever selects either

normal or 100% oxygen, but acts to select only when

the emergency pressure control lever is in the NOR-

MAL position.

When not in use, the diluter control lever

should be left in the 100% OXYGEN

position to prevent regulator contamina-

tion.

(2.) The emergency pressure control lever

has three positions. Two positions control oxygen

consumption for the individual using oxygen, and

the remaining position serves for testing hose and

mask integrity. In the EMERGENCY position, the

control lever causes 100% oxygen to be delivered at

a safe, positive pressure. In the NORMAL position,

the lever allows delivery of normal or 100% oxygen,

depending upon the selection of the diluter control

lever. In TEST MASK position, 100% oxygen at

positive pressure is delivered to check hose and

mask integrity.

(3.) The 500 PSI oxygen pressure gage

provided on the oxygen control panels should never

2-50