T.O. 1-1A-9

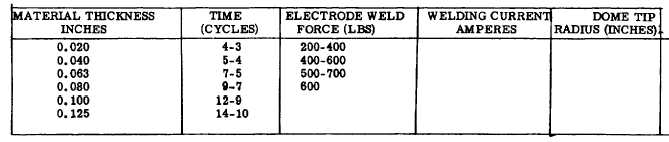

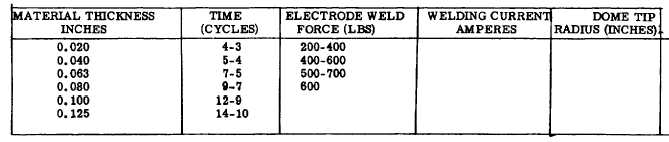

TABLE 4-28. SPOT WELDING AX31B SINGLE PHASE AC SINGLE WELD FORCE.

4-89. The second type of AC spot welding is done using a three phase frequency converter operation. This also is

referred to as pulsation welding. Line voltage and frequencies are transformed into single direction current pulses by

transformers and controls. Standard machines produce from 1 to 5 pulses. Table 4-29 gives reference data for welding

with these machines. Although this table only presents single weld force data, dual force operation with both weld and

force pressure applied makes welding of the alloys possible at lower current and electrode forces. Best general weld-to-

forge force is about 1-1 to ½ -2.

4-90. Electrostatic spot welding is accomplished using DC transformer-condenser machines operated on the principal of

electrical current from step-up transformer being stored by condensers and then discharged through the electrodes and

the alloy metals. The resulting heat, when used with correct pressure and under proper timing and intensity control, will

effectively weld the metal together. The intensity of available current is governed by the transformer; turn ratio 480:1 is

the best for magnesium.

4-91. A means of reversing current flow direction or polarity should be provided since electrode tip life can be greatly

extended if the polarity is reversed for each successive weld. An example for this type welding is given in Table 4-30.

Using this method with automatic operation, however, requires speed control reduction 'o insure full charging of the

condenser before discharge, otherwise inconsistent welding may occur.

4-92. Beam welding in done in a manner similar to spot welding with the added advantage that a continuous fluid and

gas tight seam can be made by overlapping the welds. Shear strength compares very favorably to those of conventional

spot welds; e.g., 10752250 lbs/linear inch for 0.040 0.0125" thick AZ31B alloy.

4-93. MAGUESIUM ALLOY SURFACE TREATMENT.

4-94. Some magnesium surface treatments outlined in, Military Spec MIL-M-3171 for corrosion protection and producing

suitable paint surfaces are as follows:

a.

Type I - Chrome-Pickle Treatment used for temporary storage, domestic shipment, electrical bonding and touch-

up of previously treated work. Applicable to all alloys when close dimensional tolerance is not required (commercially

known as DOW No. 1).

b.

Type II - Dichromate Treatment For general long time protection of all alloys except magnesium cerium and

magnesium-manganese alloys (commercially known as DOW No. 7).

c.

Type IV - Galvanic Anodizing Treatment For general long time protection of all alloys when close dimensional

tolerances are required (commercially known as DOW No. 9).

d.

Type VI - Chromic Acid Brush -Or Treatment For temporary storage, protective touch-up of previously treated

work, and brush application where parts and assemblies are too large to be immersed. Applicable to alloys when close

dimensional tolerances are not required (commercially known as DOW No. 19).

e.

Type VII - Fluoride Anodizing Treatment For cleaning of magnesium alloys as a substitute for shot or grit

blasting, by providing a relatively inert film when close dimensional tolerances are required and a good base favorable to

paint adhesion (commercially known as magnesium elektron fluoride anodize).

4-95. T.O. 42C2-1-7 provides instructions covering the procedures to be used in the processing of magnesium base

alloys for the coatings listed above. Additional types of treatments (anodic) are specified by "IL Specification MIL-M-

45202. Application of some methods also cited in T.O. 1-1-2 andT.O. 1-1-8.

4-38