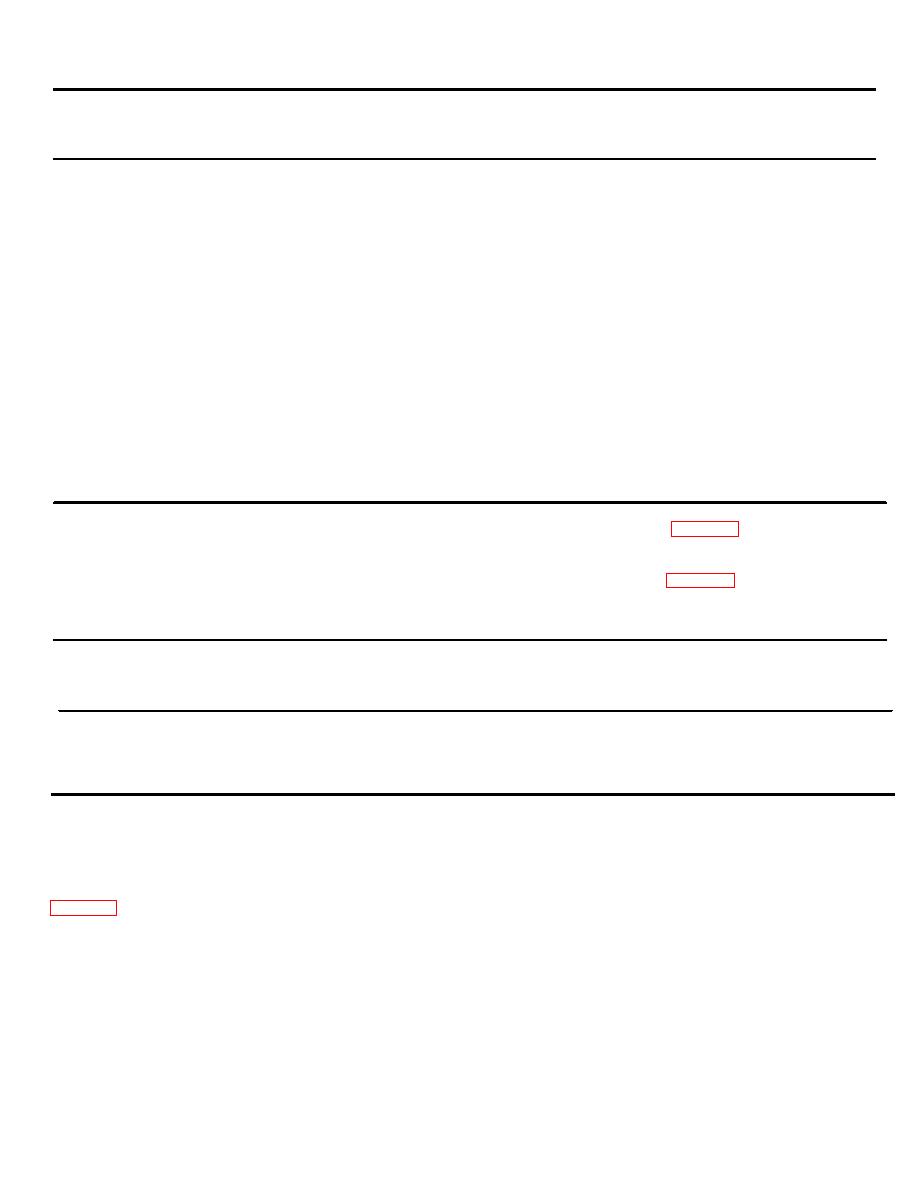

TM 55-6610-247-40

Table 3-2. Scale Error Test

STANDARD

EQUIVALENT

SCALE ERROR

ALTITUDES

ATMOSPHERIC PRESSURE HG

TOLERANCE

PRESSURE MERCURY

FEET

MM

INCHES

FEET

0

760.0

29.92

*20

500

746.4

29.39

20

1,000

732.9

28.86

*20

1,500

719.7

28.33

25

2,000

706.6

27.82

*30

3,000

681.1

26.81

30

4,000

656.3

25.84

*35

5,000

632.4

24.89

40

6,000

609.0

23.98

*40

8,000

564.4

22.22

*60

10,000

522.6

20.58

*80

12,000

483.3

19.03

*90

14,000

446.4

17.57

*100

16,000

411.8

16.21

*110

18,000

379.4

14.94

*120

20,000

349.1

13.75

*130

22,000

320.8

12.63

*140

25,000

281.9

11.10

*155

30,000

225.6

8.88

*180

35,000

178.7

7.04

*350

point or points as listed in table 3-4 take two readings:

corrected by either of the methods described above,

first, before tapping instruments, and, second, after

diaphragm assembly must be replaced.

tapping it. Change in reading of pointers shall not

3-8. Friction Test.

exceed tolerances given in table 3- 4.

Test for friction as follows:

a. While holding pressure constant at any

Table 3-3. Hysteresis and After Effect

EQUIVALENT

PERMISSIBLE

STANDARD

ATMOSPHERIC

VARIATION

ALTITUDE

PRESSURE

FROM SCALE

TEST POINTS

IN FEET

(MM HG)

ERROR (FEET)

First Hysteresis

18,000

379.4

75

Test Point

Second Hysteresis

14,000

446.4

75

Test Point

After Effect

Local Pressure

30

b. While operating instrument at rate corresponding

(2) From 25,000 to 30,000 feet, movement of

pointer must be smooth although not necessarily regular

to an increase in altitude of approximately 3,000 feet per

when vibration is applied.

minute, a further check for friction is as follows:

(3) This test may be combined with test for scale

(1) From 0 to 25,000 feet, without vibration, pointer

error.

must not jump more than indicated tolerances given in

(4) If instrument fails to meet this test, it must be

disassembled and cleaned.

3-3