TM 55-1730-201-12

CHAPTER 3

OPERATOR AND ORGANIZATIONAL MAINTENANCE INSTRUCTIONS

Section I. OPERATOR AND ORGANIZATIONAL TOOLS, EQUIPMENT AND LUBRICATION

21. SPECIAL TOOLS AND EQUIPMENT.

No special tools or equipment are required to per-

form operator and organizational maintenance on

the maintenance platform.

22. LUBRICATION.

a. General Lubrication Information. This section

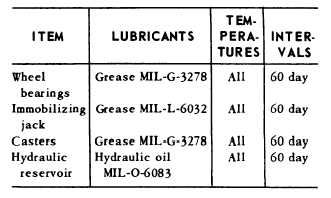

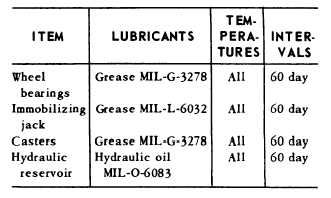

contains a lubrication chart (table 1) which is sup-

plemented by the detailed lubrication information

contained in b below.

b. Detailed Lubrication Information.

(1) Care of Lubricants and Lubrication Equip-

ment. Keep all lubricants in closed containers and

store in a clean, dry area away from heat. Do not

allow dirt, dust, water, or other

23. GENERAL.

To ensure that the equipment

tion at all times, it must be

foreign material to

come in contact with the lubricants. Keep all lu-

brication equipment clean and ready to use.

(2) Points of Application. Follow the detailed

lubrication instructions given in the chart below.

Table 1. Lubrication Chart

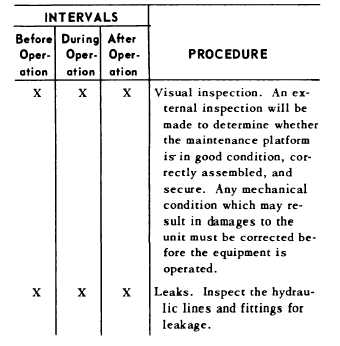

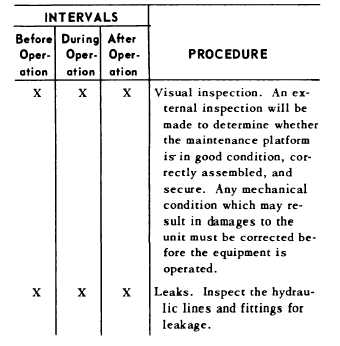

Section II. PREVENTIVE MAINTENANCE SERVICES

is ready for opera-

inspected system-

atically before operation, during operation, and

after operation, so defects may be discovered and

corrected before they result in serious damage or

failure.

The necessary preventive maintenance

services will be performed before operation. De-

fects discovered during operation of the unit will

be noted for future correction, to be made as soon

as operation has ceased. Stop operation immediate-

ly if a deficiency is noticed during operation which

would damage the equipment if operation is con-

tinued. After-operation services will be performed

by the operator after every operating period. After-

operation services will be performed at intervals

based on the normal operation of the equipment.

Reduce interval to compensate for abnormal condi-

tions.

Defects or unsatisfactory operating charac-

teristics beyond the scope of the operator to cor-

rect must be reported at the earliest opportunity

to organizational maintenance. Responsibility for

performance

of preventive

maintenance services

rests not only with the operator, but with the en-

tire chain of command from section chief to com-

manding officer (AR 750-5).

24. OPERATOR’S DAILY SERVICES.

7