T.O. 1-1A-9

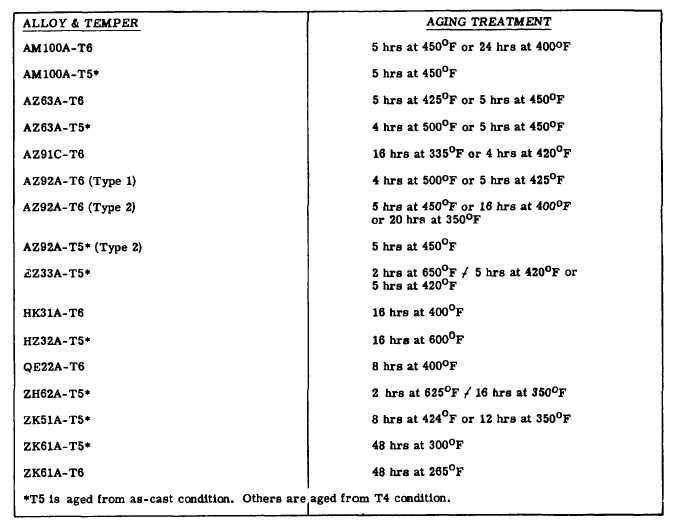

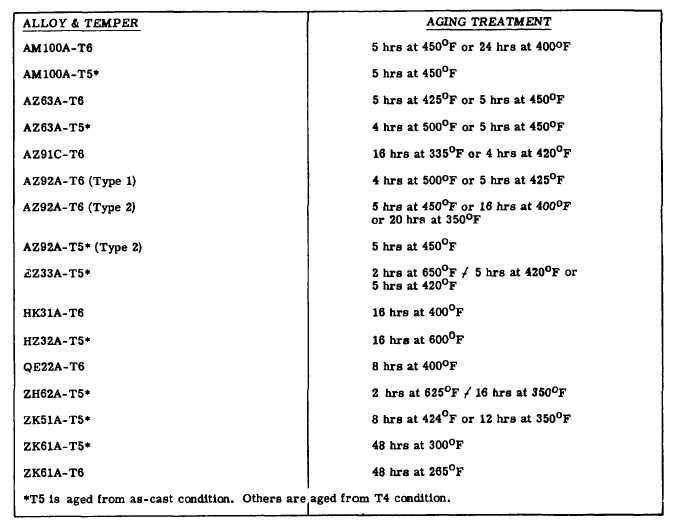

TABLE 4-9. ARTIFICIAL AGING (PRECIPITATION TREATMENT)0

b.

AZ31B and C - Used in low cost extruded bars, rods, shapes, structural sections and tubing with moderate

mechanical properties and high elongation sheet and plate; good formability and strength, high resistance to corrosion,

good weldability. Liquid temperature 1170F; solid 1120°F. Hot working temperature is 450 - 800°F. Annealing

temperature 650F. Stress relief of extrusions and annealed sheet :500°F for 15 minutes; hard rolled sheet = 300

F for

60 minutes. Welding done with helium argon arc using AZ61A or AZ92A rod. Gas welding is not in general use but

resistance welding is. Stress relieve after welding. Foreign equivalents are: British DTD 120A Sheet, 1351350 forgings;

German and Italian, Electron AZ31; French SOC Gen Air Magnesium, F3 and T8.

c.

AZ61A - Use in general purpose extrusions with good properties, intermediate cost; press forgings with good

mechanical properties. Rarely used in sheet form. Hot working temperature 350-750F; shortness temperature above

780°F. Anneal 650°F. Heat treat annealed sheet extrusions and forgings 15 minutes at 500

F rolled sheet 400F for 15

minutes. Weld with helium or argon gas using AZ61A or AZ92A. Resistance welding in satisfactory. Stress relieve after

welding. Foreign equivalents are British BS 1351 (forgings) BS 1354 (extrusions); German AZM.

d.

AZ63A - Used in sand castings for good strength properties with best ductility and toughness. Solution heat treat

at 740°F in a 0.5%-SO2 atmosphere for 10 hours then cool in air. Aging is done at 450°F for 5 hours and cooled in air or

furnace. Stabilize at 300F at 4 hours and cool in air. Foreign equivalents are Elektron AZG, British DTD59A (as cast)

and DTD289 (heat. treated). Good salt water anti-corrosion properties.

e.

AZ80A - Used for extruded and press forged prodc4cts. Heat treatable. Hot working temperature 600-750

F.

Shortness temperature above 775F, annealing temperature 725 F. Stress relief: as extruded, 500F for 15 minutes;

extruded and artificially aged 400°F for 60 minutes; forgings 500for 15 minutes. Foreign equivalents are British 1351

(forgings); German AZ855 Helium or Argon-arc weldable using AZ92A welding rod or may be resistance welded. Stress

relieve after welding.

4-19