T.O. 1-1A-9

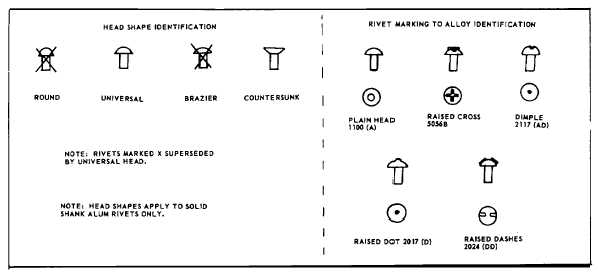

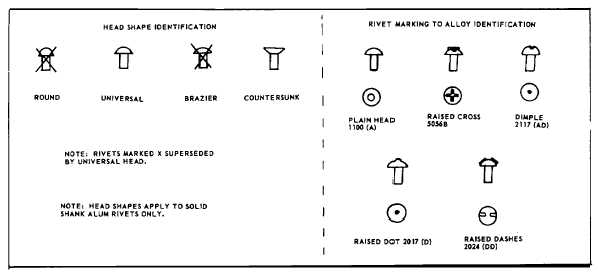

TABLE 3-17. GENERAL RIVET (ALUM) IDENTIFICATION CHART.

CAUTION

Heat treatment and most other operations

requiring use of heat will be accomplished

prior to installing rivets, since heating after

rivets are installed will cause warping and

possible corrosion if salt bath is used. The

salt from the bath will contaminate cracks

and crevices of the assembly and complete

removal cannot be assured.

3-168. Shear strength (ultimate) of a driven rivet can be

determined by the formula Ps=SsAN. Ps=ultimate

shear strength (pounds), Ss=specified shear strength of

the driven rivet (psi), A=cross sectional (area of the

driven rivet, normally equal to hole cross section

(square inch) and N=number of shear planes. For shear

strength of protruding and flush head rivets see Table 3-

19.

3-170. Rivet Selection. Unless otherwise specified,

rivets should be selected that have comparable strength

and alloy as material being assembled. This is an

important factor in preventing corrosion from dissimilar

metal

contact

and

to

assure

structurally

sound

assemblies. The following tables are provided as a

general guide for selection of rivet alloy vs. assembly

alloy.

3-171. The formula Ps = Sb AC can be used to

determine failure in bearing strength. Ps = ultimate

bearing strength of the joints (lbs), Sb = specified

ultimate bearing strength of the plate (psi) and Ac =

projected crushing area (bearing area) of rivet, or

diameter (sq in) see Table 3-20 for typical bearing

properties of aluminum alloy plates and shapes.

3-172. Rivet hole preparation is one of the key factors

in controlling (1) successful upsetting of rivet head (2)

material separation and buckling which weakens the

structural strength of the rivet joint (3) corrosion attack

of rivets and material after equipment is placed in

service/use. The rivet hole should be drilled,

punched/reamed to size that allows the minimum

clearance (approximately 0.003 for thin sheet and up to

about 0.020 for 0.750 - 1.000 inch thick material)

required to insert rivet without forcing. Theoretical rivets

holes should be completed i.e., drilled, reamed to size,

deburred, chips removed that may lodge or be trapped

in between surface of metal and treated (anodized, etc.)

before starting to rivet assembly. The above cannot

always be accomplished, especially where the assembly

is large and requires the application of a large amount of

rivets due to hole tolerance and variations in holding

clamping/pressures. To overcome these problems

requires that holes be pilot drilled and reamed to size at

time rivet is to be installed. This method has a twofold

purpose (1) allows easy insertion of rivets, (2) prevents

elongation of rivet holes and resulting weakening of rivet

joint.

3-173. Rivet holes drilled/reamed after assembly is

started should be treated by coating with zinc chromate

primer or other approved material. Two methods for

coating rivets and improving protection of hole surfaces

from corrosion are:

3-37