T.O. 1-1A-9

2-300. VAPOR DEPOSITED COATING. Vapor deposited coating's are applied by exposing the base metal to a heated vaporized

metallix coating such as cadmium and aluminum in a high vacuum. The metal coating forms by condensation of the vaporized

coating metal on all exposed surfaces of the base metal. Vapor-deposited coatings can be obtained by processes in which a volatile

compound of the coating is reduced or thermally decomposed upon the heated surface of the base metal. Vapor deposited coatings

are used to provide good corrosion resistance for steel and eliminate sources of hydrogen embrittlement. Specific requirements for

coating, aluminum vacuum deposited, are cited in specification MIL-C-23217A; and for coating, cadmium vacuum deposited, in

specification MIL-C8837.

2-301. MECHANICAL-SURFACE FINISH . The following paragraphs are concerned with mechanical surface finish of the

geometrical irregularities of surfaces of solid materials and established classification for various degrees of roughness and waviness.

The surface roughness of a part is a measurement rating of the finely spaced irregularities, such as the surfaces produced by

machining and abrading (abrasive honing, grinding, filing, sanding, etc.) The roughness height ratings are specified in micro inches

as the arithmetic average of the absolute deviations from the mean surface. Profilometers and other instruments used to measure

surface height if calibrated in RMS (Root Mean Square) average will read approximately 11% higher on a given surface than those

calibrated for arithmetic average. Also associated with roughness high is roughness width, usually specified in inches and the

maximum permissible spacing of surface irregularities. As the arithmetic average of the absolute deviations from the mean surface.

Waviness height rating (when required) may be specified in inches as the vertical distance from peaks to valleys of the waves,

whereas waviness width is the distance in inches from peak to peak of the waves. Figure 2-5 shows the meaning of each symbol

defined.

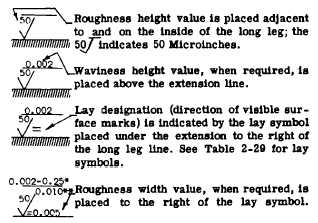

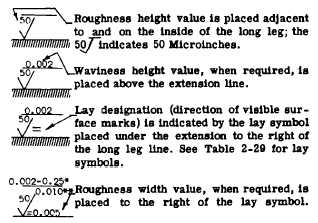

2-302. The symbol used to designate surface irregularities is the check mark as shown below.

*When waviness width value is required, the value may be placed to the right of the waviness height value.

**Roughness width cutoff value, when required, is placed immediately below the right-hand extension.

2-303. Designation of Surface Finish. Surface finish should be specified for production parts only on those surfaces which must be

under functional control. For all other surfaces the finish resulting from the machining method required to obtain dimensional

accuracy is generally satisfactory. The surface chosen (unless already designated) for a specific application will be determined by its

required function. Table 2-29 gives the typical normal ranges of surface roughness of functional parts. The values cited are micro

inches, for example 63T= 63 Micro inches or 0.000063 inches average deviation from mean.

TABLE 2-28. GALVANIC SERIES OF METALS AND ALLOYS.

CORRODED END ANODIC (LEAST NOBLE)

Magnesium

Tin

Magnesium Alloys

Nickel (active)

Zinc

Inconel (active)

Aluminum 7075 Clad

Brass

Aluminum 6061 Clad

Copper

Aluminum 5052

Bronze

Aluminum 2024 Clad

Titanium

Aluminum 3003

Monel

Aluminum 6061 T6

Silver Solder

Aluminum 7075 T6

Nickel (Passive)

Aluminum 7178

Inconel (Passive)

Cadium

Silver

Aluminum 2017 T4

Graphite

Aluminum 2024 T6

Gold

Aluminum 2014T6

Platinum

Steel or Iron

Protected End Cathodic

Lead

(Most Noble)

2-127