T.O. 1-1A-9

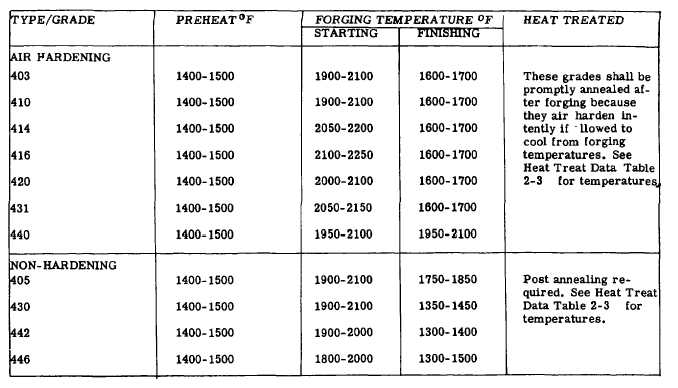

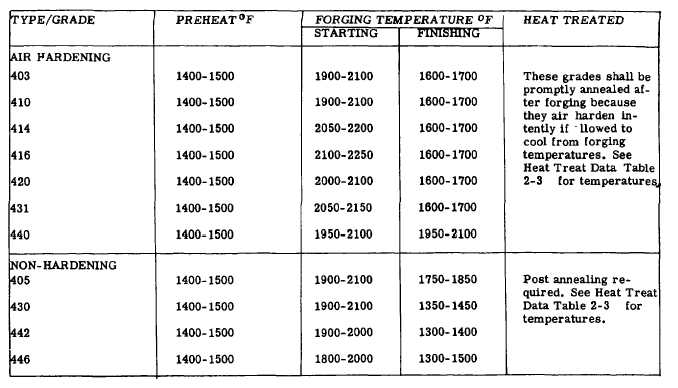

TABLE 2-27. FORGING TEMPERATURE RANGES FOR CORROSION RESISTANT STEEL (CONT'D)

2-268. The straight chromium grades such as 410, 416, 430, 442, and 446 react similar to carbon steel and are

somewhat less ductile than the 300 series stainless. The tensile strength are higher than carbon steel and consequently

will stand higher loads before rupture. Yield strengths are also higher which means that more power is required for

bending and forming. Because of the ductility factor of this series drawing and forming should be limited to 20 25%

reduction.

2-269. The 301, 302, 304, 305 and 316 types can be drawn based on a reduction of 35 to 50%, i.e.. a shape 8 inches in

diameter and 4 inches in depth could be drawn in one operation, based on a 50% reduction.

2-270. The strains set up by severe reductions (above 45% with chromium-nickel types and 20% with straight chromium

types) should be relieved by annealing immediately after the operation is completed, especially if using type 301. If this

material is not relieved in 2 4 hours, it may crack.

2-271. Springback allowance should be about 2 to 3 times the amount allowed for carbon steel, and naturally will vary

according to the type of material being formed. The use of sharp radii shall be avoided where parts are subjected to

flexing or concentrated stresses due to possible fatigue or stress corrosion failure.

2-272. Recommended bend radii for use with stainless is shown in Table 2-26.

2-273. Draw Forming. Stainless steels should be annealed for draw forming, and hardness should not exceed Rockwell

B90. The best drawing grades are of the 18-8 series. In selecting the type for drawing, welding of the finished parts, if

required, shall be considered.

2-274. Drop H2mmer Forming. The most common types of corrosion resistant steel used for drop hammer forming are

301, 302, 304, 305, and stabilized grades 321 and 347. 301 work hardens more rapidly and is subject to strain cracking.

The condition of material for best forming should be annealed. It is possible to form some type (301 and 302) in 1/4 and

1/2 hard condition. However, the severity of the forming operation must be reduced to compensate for the prehardened

material.

2-275. Spinning. Spinning procedures for stainless are similar to those used for other metals. Difficulty and variations

depend on individual characteristics of grade to be worked, i.e., yield strength, ultimate strength, ductility, hardness and

reaction to cold working. The best grades for spinning are those that have low yield strength in soft/annealed condition

and low rate of work hardening such as 304, 305, 403, 410 and 416. The straight chromium grades respond to spinning

similar to carbon steel, however, more power is required. Mild warming above 200°F improves performance of the

straight chromium grades.

2-121