TM 1-1510-223-10

Change 3 9-5

12. ENG START switch — OFF after TGT peaks.

13. CONDITION lever — HIGH IDLE.

14. PROP lever — As required.

15. POWER lever — As required.

16. Engine cleanup — Perform if engine start was

unsuccessful.

17. GENERATOR switch — RESET, then ON.

18. Engine AUTO IGNITION — As required.

19. PROP SYNC switch — As required.

20. Electrical equipment — As required.

21. Cabin air mode switch — As required.

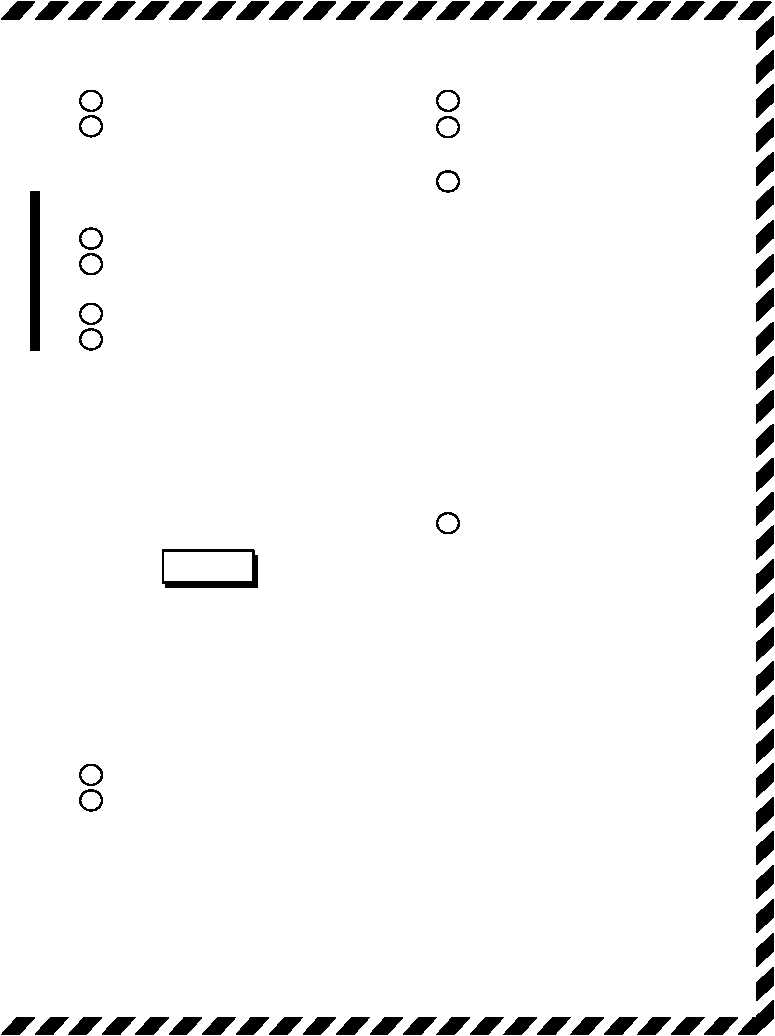

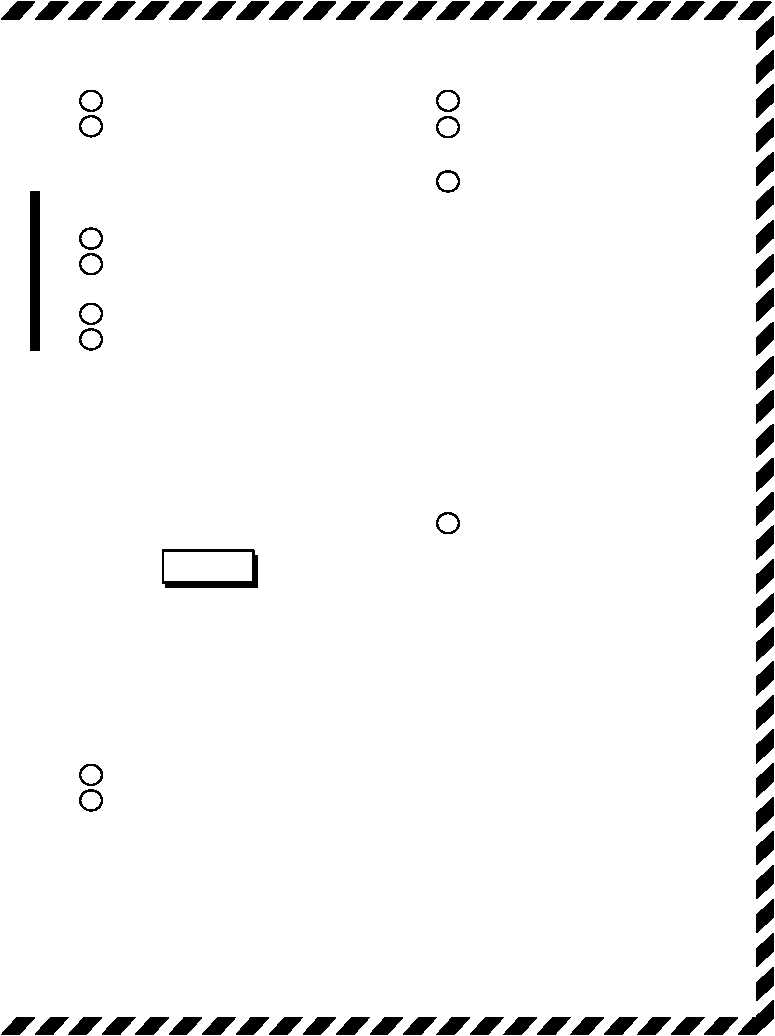

9-11. MAXIMUM GUIDE.

In the event of failure of both engines, maximum glid-

ing distance is obtained by feathering both propellers to

reduce propeller drag and by maintaining the appropriate

airspeed with the gear and flaps up. Figure 9-2 gives the

approximate gliding distances in relation to altitude. The

procedure to follow in the event of failure of both engines

is as follows:

1. Gear — UP.

2. Flaps — UP.

WARNING

Determine that procedures for restarting first

and second failed engines are ineffective before

feathering second engine propeller.

3. PROP levers — FEATHERED.

4. Airspeed — As required (fig. 9-2).

9-12. SINGLE-ENGINE DESCENT/ARRIVAL.

Perform the following procedure prior to the final de-

scent for landing:

1. CABIN CONTROLLER — Set.

2. ICE & RAIN switches — As required.

3. RECOG lights — On.

NOTE

Set windshield anti-ice to NORMAL as required

well before descent into icing conditions or into

warm moist air to aid in defogging. Turn off wind-

shield anti-ice when descent is completed to

lower altitudes and when heating is no longer

required. This will preclude possible wind screen

distortions.

4. Windshield anti-ice — As required.

5. Radio altimeter — As required.

6. Altimeters — Set to current altimeter setting.

7. ASE — As required.

8. Flare/chaff dispenser safety pin — Insert.

9. Arrival briefing — Complete.

NOTE

When landing with one engine inoperative,

maintain airspeed at a minimum of Vyse until

landing is assured. A go-around after flaps are

fully extended may not be possible.

9-13. SINGLE-ENGINE BEFORE LANDING.

1. PROP lever — HIGH RPM.

2. Flaps — As required.

3. Gear — DN.

4. Landing lights — As required.

5. Yaw damp — Off.

6. BRAKE DEICE switch — Off.

9-14. SINGLE-ENGINE LANDING CHECK.

Perform the following procedure during final ap-

proach to runway.

1. Autopilot/yaw damp — Disengage.

2. GEAR DOWN lights — Check.

3. PROP lever (operative engine) — HIGH RPM.

NOTE

To ensure constant reversing characteristics,

the propeller control must be in the HIGH RPM

position.

4. Flaps — As required.

9-15. SINGLE-ENGINE GO-AROUND.

The decision to go around must be made as early as

possible. Elevator forces at the start of a go around are

very high, and a considerable amount of rudder control

will also be required at low airspeeds. Retrim as required.

If rudder application is insufficient, or applied too slowly,

directional control cannot be maintained. If control diffi-

culties are experienced, reduce power on the operating

engine. Insure that the aircraft will not touch the ground