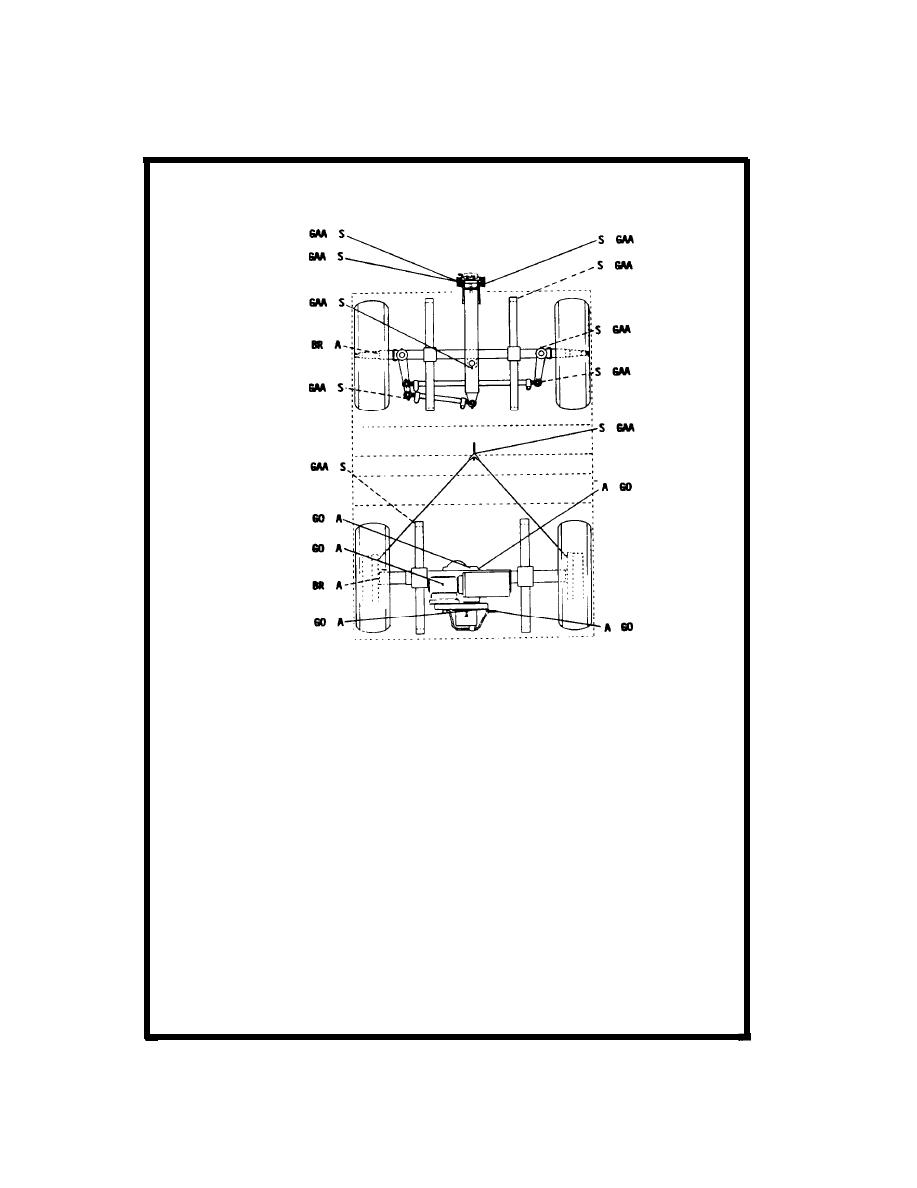

Tow Bar Latch Pivot

Tow Bar Latch

(See Note 2) (H)

(See Note 2) (H)

Tow Bar Pivot

Spring Eyes

(1 fitting) (G)

(See Note 3) (I)

Tongue Horizontal Pivot

(1 fitting) (F)

Steering Knuckle

Bearing (Top and

Front Wheel Bearing

and Bottom) (E)

(Annually remove,

clean, dry, repack hub)

Tie Rod Ends

(2 fittings) (C)

Steering Drag Link

(2 fittings) (D)

Brake Cable

Assembly

(See Note 5) (J)

Spring Eyes

(See Note 3) (I)

Rear Axle

Rear Axle Differential

Differential

Fill and Level (Check

Drain (Drain

level) (See Note 4) (A)

and Refill )

(See Note 4) (B)

Gear Drive Fill (Drain

and Refill) (See Note 4)

Rear Wheel Bearings

(Annually remove, clean,

dry, repack hub)

Chain Drive Housing Fill

Chain Case

and Level (Check Level )

Housing Drain

(See Note 4) (A)

(Drain and

Refill)

(See Note 4) (B)

5. BRAKE CABLE ASSEMBLY. Semiannually lubri-

NOTES

Drain

cate brake cable connection points with a thin

1. ENGINE GEARCASE AND OIL FILTER.

coat of GAA. Lubricate brake lever bearing

gearcase and replace oil filter semi annual 1 y or

surfaces with OE/HDO.

every 250 engine operating hours, whichever

occurs first. Drain only wisen hot after oper-

6. OIL CAN POINTS. Semiannually lubricate all

Inspect magnetic drain plug and oil

ation.

filter for metal particles. The presence of

hinges, latches, and clutch and brake linkages

with OE/HDO.

metal particles may indicate internal engine

damage. Refill with MIL-L-23699 to full mark

Copy of this lubrication order will remain with

on gearcase fill level indicator (2.3 qts).

the AGPU at all times. Instructions contained

Run engine for 15 minutes and recheck oil

herein are mandatory.

level.

2. TOW BAR LATCH. Semiannually lubricate tow By order of the Secretary of the Army:

bar latch lever bearing surfaces sparingly with

Coat latching surfaces with a thin

OE/HDO.

coat of GAA.

3. SPRING EYES. Semiannually lubricate spring

eyes with OE/HDO.

4. DRIVE GEARCASES. Drain gearcases annually.

Drain only when unit is warm after operation.

Check level at axle differential. Level should

be within 1/2 inch of plug opening when cold,

and at plug level when at operating temper-

ature.

L055-1730-229-12

CARD 2 OF 4